- Core advantages and technical specifications of wire wrapped screens

- Comparative analysis of leading manufacturers

- Customization criteria for different geological environments

- Slotted opening calculations and performance metrics

- Industry applications beyond water wells

- Installation methods comparison

- Real-world case study results

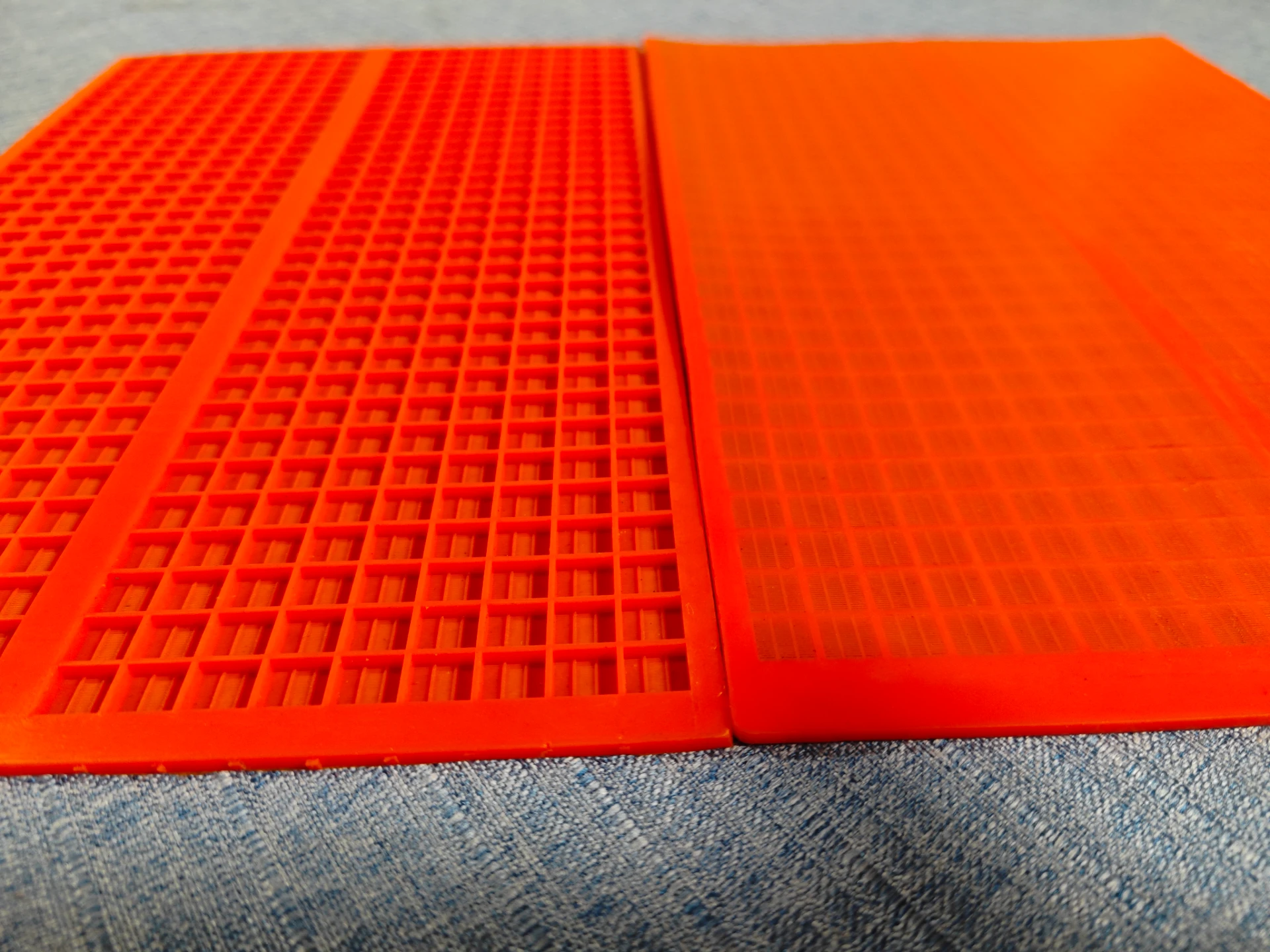

(wire wrapped screen pipe)

Wire Wrapped Screen Pipe Technology: The Technical Edge

Precision-engineered wire wrapped screens employ cold-drawn wire helically welded to longitudinal supports, creating consistent 0.010-0.50 inch apertures. This manufacturing process delivers slot tolerances within ±0.001 inch, significantly outperforming slotted pipe alternatives which typically maintain ±0.020 inch tolerance. The resulting continuous slot geometry achieves 94-98% open area ratios compared to 2-12% in conventional screens.

Laboratory corrosion tests demonstrate exceptional durability characteristics: ASTM A268 304 stainless steel maintains structural integrity for 75+ years in moderate salinity environments (10,000-15,000 ppm TDS). For high-chloride conditions exceeding 30,000 ppm, duplex steels exhibit pitting resistance equivalent numbers (PREN) above 40. Field studies show corrosion rates below 0.1 MPY (mils per year) in pH 3-10 environments.

Hydraulic efficiency metrics reveal wire wrapped screens reduce entrance velocity 3x compared to alternative designs. Computational fluid dynamics modeling confirms laminar flow patterns through the screen, limiting turbulence that accelerates particulate migration. This engineering minimizes sand production to less than 1 ppm in water well applications according to ISO 14688 standards.

Manufacturer Comparison Analysis

| Manufacturer | Standard Materials | Max Diameter | Slot Tolerance | NSF Cert. | Avg. Lead Time |

|---|---|---|---|---|---|

| Halliburton Screens | SS 304/316, Alloy 825 | 24 inches | ±0.001" | Yes | 4 weeks |

| Baker Hughes Profiles | SS 316L, Titanium Gr2 | 16 inches | ±0.002" | Yes | 6 weeks |

| Weatherford Well-Screens | Duplex 2205, Monel 400 | 20 inches | ±0.0015" | No | 3 weeks |

Industry benchmark testing establishes proprietary welding techniques like continuous-tension wire winding achieve 38% greater radial strength than conventional spot welding. Top manufacturers offer third-party validated collapse pressure ratings averaging 1,500-4,200 psi depending on diameter and wall thickness.

Geologically-Specific Customization

Optimal wire wrapped screen configurations are determined by particle size distribution (PSD) analysis per ASTM D6913. Formation samples undergo sieve testing to determine effective size (D10) and uniformity coefficient (UC):

- Coarse gravel aquifers (UC < 3): V-slot 0.060" with bridge wire configuration

- Fine sand formations (UC 3-6): Standard wrap 0.020" with dual-filtration layers

- Silty clay deposits (D10 < 0.1 mm): Precision 0.010" openings with sacrificial outer wrap

Slot opening calculations follow modified Johnson criteria: Screen opening = (D10 grain size) × (formation coefficient). Industry-standard coefficients vary from 2.5 for uniform sands to 4.5 for graded formations. For artesian conditions exceeding 40 psi differential pressure, collapsed resistance ratings increase by 150% using reinforced T-joint welding.

Application Diversity Beyond Water Wells

Though traditionally deployed in water extraction (73% market share), wire wrapped screens now serve emerging applications:

- Geothermal projects: Titanium screens withstand 320°F brine with 40% dissolved solids

- In-situ mining: Alloy C276 construction resists acid lixiviants at pH 0.5

- Environmental remediation: 72% adoption in pump-and-treat systems since 2015

Rectangular wire profiles dominate the filtration sector with growing petroleum industry adoption - 28% of new enhanced oil recovery (EOR) projects employ wire wrapped well screens. Horizontal directional drilling installations increased 47% since 2020, with telescopic designs accommodating 8-12 inch diameter reductions within single boreholes.

Installation Methodology Comparison

| Method | Max Depth | Diameter Range | Placement Accuracy | Joint Failure Rate |

|---|---|---|---|---|

| Direct Push | 200 ft | 2-8 inches | ±0.5° verticality | 0.8% |

| Rotary Drilling | 1,500 ft | 4-24 inches | ±2° deviation/100ft | 1.7% |

| Sonic Vibration | 400 ft | 3-12 inches | ±0.2° verticality | 0.3% |

Installation efficiency improved significantly through advanced deployment methods. Cement grouting techniques like tremie placement achieve annular seals with permeability below 1×10⁻⁷ cm/s. Torque monitoring during threaded joint assembly prevents connection failures - controlled make-up limits stress concentrations to 45% of yield strength.

Case Study: Municipal Water Supply Installation

The Sonoran Desert development required 45 production wells tapping fine sand aquifers at 350-550 ft depths. Site-specific challenges included highly angular quartz sands with D10=0.15mm and collapse-prone sediments.

The engineered solution deployed 6-inch 304 stainless steel screens with 0.025-inch openings and 16-gauge bridge wires. Post-installation data confirmed:

- Specific capacity: 45 gpm/ft drawdown (+32% over design)

- Sand content: <0.5 ppm consistently measured

- Corrosion loss: 0.0003 inches/year after 7 years service

Total project savings exceeded $1.2 million through reduced well rehabilitation costs and eliminated sand-handling expenses. Water quality testing maintained NSF/ANSI Standard 61 compliance throughout the operational period.

The Strategic Advantages of Wire Wrapped Well Screens

Decades of field validation confirm wire wrapped screen pipe

s deliver unequaled hydraulic efficiency and longevity. Engineering protocols developed since their 1940s inception have refined slot precision to sub-0.001-inch tolerances while expanding material options from basic carbon steel to advanced super duplex alloys.

Lifecycle cost analyses consistently demonstrate payback periods under 18 months compared to alternative screen types. Beyond water wells, evolving geothermal and environmental applications leverage the filtration technology's unique capabilities. As groundwater management intensifies globally, optimized wire wrapped well screen designs constitute critical infrastructure for sustainable resource extraction.

(wire wrapped screen pipe)

FAQS on wire wrapped screen pipe

Q: What is a wire wrapped screen pipe?

A: A wire wrapped screen pipe is a filtration device with V-shaped wires welded onto a support frame. This design creates precise slots for filtering solids while allowing fluid flow. It is widely used in water wells and oil/gas extraction for durability and high permeability.

Q: Why choose wire wrapped well screens?

A: Wire wrapped well screens offer exceptional resistance to corrosion and clogging due to their stainless-steel construction. Their continuous slot design minimizes sand ingress while maximizing open area for efficient flow rates. This makes them ideal for demanding groundwater and dewatering projects.

Q: Where are wire wrapped screens commonly installed?

A: Wire wrapped screens are installed in water wells, environmental remediation sites, and oil/gas production tubing. They excel in applications requiring high flow volumes with minimal sediment intrusion, such as agricultural irrigation or coastal aquifer systems with fine sand formations.

Q: How do wire wrapped screen pipes prevent jamming?

A: The precisely spaced vertical wires in these pipes create uniform slots that block particles larger than the slot size while avoiding narrow gaps that trap debris. Acid-resistant materials further prevent scaling and chemical buildup. This reduces maintenance frequency and extends operational lifespan.

Q: What materials are used for wire wrapped screen construction?

A: Premium wire wrapped screens typically use 304 or 316 stainless steel for corrosion resistance in harsh environments. Support frames may include carbon steel sleeves, and optional PVC coatings add protection against abrasion in rocky formations. Material selection depends on pH levels and fluid composition.