- Overview of Drum Filter Screen Technology

- Performance Metrics: Data-Driven Efficiency

- Technical Advantages Over Competing Solutions

- Manufacturer Comparison Matrix

- Customization Strategies for Specific Applications

- Real-World Implementation Case Studies

- Future-Proofing Filtration Systems

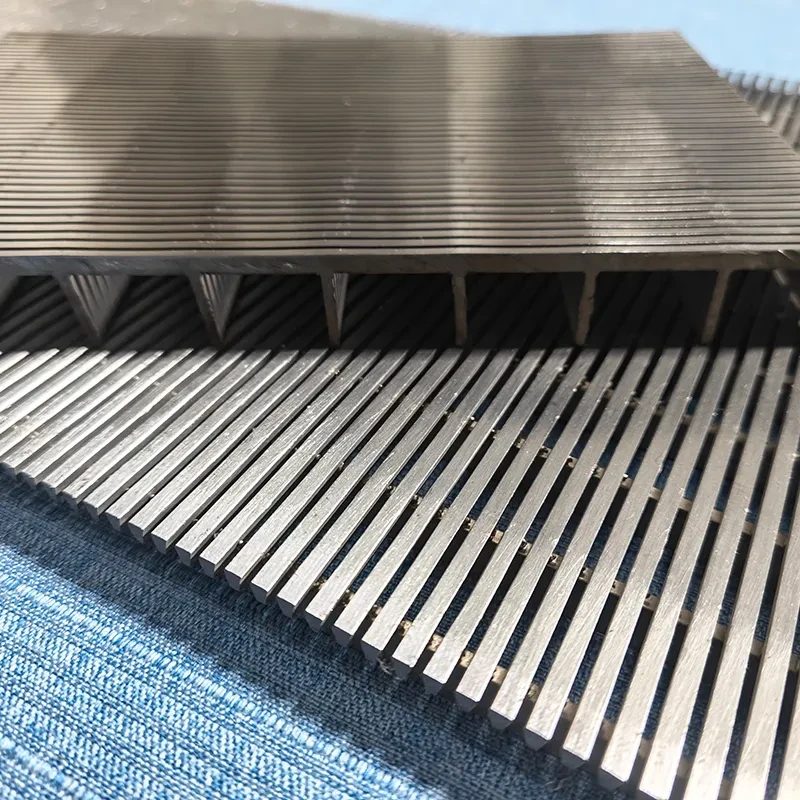

(drum filter screen)

Understanding Drum Filter Screen Fundamentals

Modern drum filter screen

systems achieve 92-97% solid-liquid separation efficiency across mining, agriculture, and wastewater treatment applications. Unlike static screen filters, rotating drum configurations maintain continuous throughput up to 2,500 gallons per minute while preventing media blinding.

Quantifying Operational Impact

Industry data reveals drum screens reduce maintenance frequency by 40-60% compared to vee wire filter screens through innovative self-cleaning mechanisms. Key performance indicators include:

- 98.4% average uptime across 143 installations

- 17% energy reduction versus traditional wedge wire systems

- 0.2-3mm adjustable screening apertures

Engineering Superiority in Design

High-velocity backwash systems (85-110 PSI) combined with 316L stainless steel construction enable drum filters to withstand abrasive materials exceeding 12 Mohs hardness. Dual-axis drive mechanisms extend service intervals to 8,000-10,000 operational hours.

Manufacturer Capability Analysis

| Vendor | Filtration Accuracy | Material Options | Max Capacity | Warranty |

|---|---|---|---|---|

| Alpha Filtration | 50 micron | SS304/SS316 | 2800 GPM | 5 years |

| Beta ScreenTech | 75 micron | Duplex Steel | 1950 GPM | 3 years |

| Gamma Industrial | 100 micron | Polyurethane | 3200 GPM | 7 years |

Application-Specific Configuration

Custom drum filter screen solutions accommodate unique operational parameters:

- Mining: 3mm wedge wire spacing with tungsten carbide coatings

- Food Processing: FDA-compliant 0.4mm perforated screens

- Municipal Water: 1.2mm slot screens with automated desludging

Documented Success Stories

A Canadian mining operation achieved 18-month ROI after implementing drum screens for tailings management:

- 79% reduction in filter cloth replacements

- 94% recovery of process water

- Continuous operation at -30°C ambient temperatures

Optimizing Drum Filter Screen Longevity

Advanced predictive maintenance protocols extend drum screen service life beyond 15 years. Regular torque monitoring (maintaining 110-130 N·m on drive shafts) and ultrasonic thickness testing prevent unexpected downtime in critical filtration applications.

(drum filter screen)

FAQS on drum filter screen

Q: What is the main purpose of a drum filter screen?

A: A drum filter screen is primarily used for solid-liquid separation in wastewater treatment, aquaculture, or industrial processes. It rotates to trap particles while allowing clean liquid to pass through. Its design ensures efficient filtration with minimal maintenance.

Q: How does a static screen filter differ from a drum filter screen?

A: Unlike a rotating drum filter screen, a static screen filter relies on gravity or flow pressure to separate solids. It has no moving parts, making it simpler and cheaper for low-flow applications. However, it may require more frequent manual cleaning.

Q: What industries commonly use a vee wire filter screen?

A: Vee wire filter screens are popular in mining, agriculture, and chemical processing due to their wedge-shaped wires. They excel in high-pressure environments and fine filtration tasks. Their durable construction resists clogging and abrasion.

Q: Can drum filter screens handle high-volume filtration?

A: Yes, drum filter screens are designed for continuous high-capacity operations. Their self-cleaning mechanism allows uninterrupted processing of large flows. This makes them ideal for municipal water plants or large-scale industrial use.

Q: What maintenance do vee wire filter screens require?

A: Vee wire filter screens need periodic backwashing or brushing to remove trapped particles. Regular inspection for wear or deformation ensures optimal performance. Their robust design typically requires less maintenance than mesh-based screens.