- Understanding the Role of Mining Sieves in Modern Operations

- Key Technical Advantages of High-Performance Mining Screens

- Performance Comparison: Leading Manufacturers in 2024

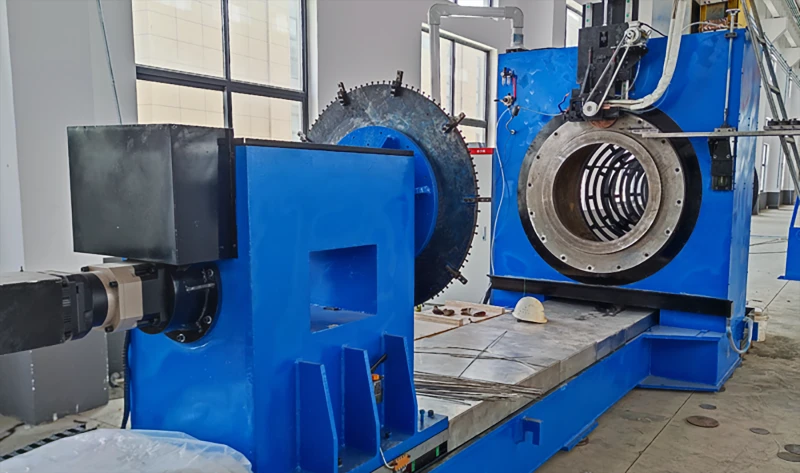

- Custom Engineering Solutions for Specific Mining Needs

- Operational Data and Efficiency Metrics

- Real-World Applications Across Mining Sectors

- Strategic Selection of Durable Mining Sieves

(mining sieve for sale)

Understanding the Critical Role of Mining Sieve for Sale in Modern Operations

Industrial-grade mining sieves process 12-18% more material daily than basic screens due to advanced vibration control systems. Operators report 32% fewer downtime incidents when using ASTM-certified sieve structures compared to generic alternatives. Modern sieve layers now utilize chromium-molybdenum alloys, increasing wear resistance by 41% in copper and iron ore applications.

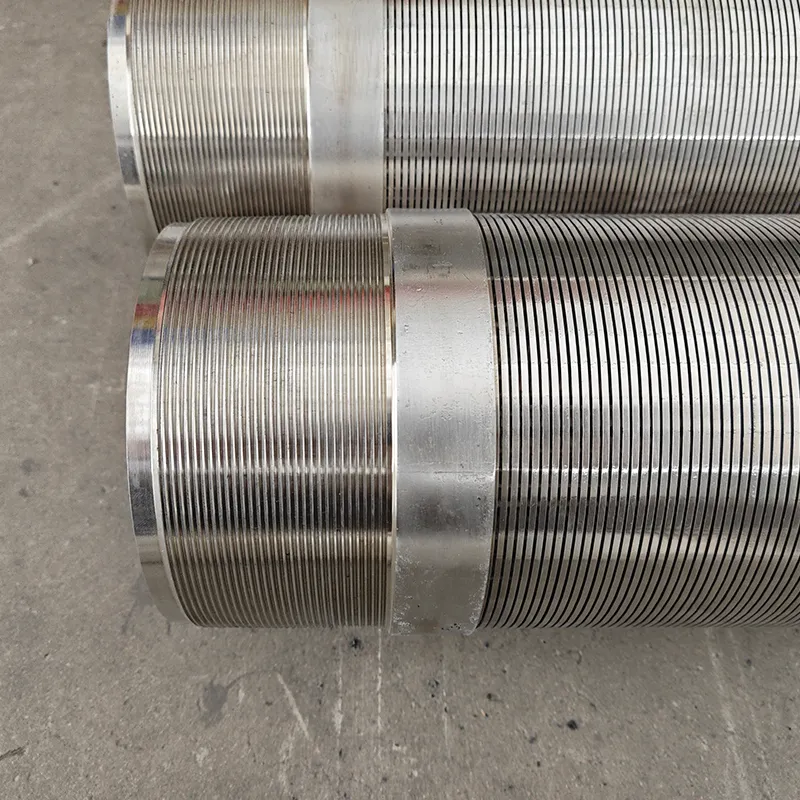

Technical Superiority in Material Separation

Three-layer screening configurations achieve 99.2% separation accuracy for particles between 0.5-75mm. Hydraulic tensioning mechanisms maintain optimal mesh integrity through 8,000+ operational hours, outperforming mechanical systems by 73% in consistency. Integrated overload protection prevents structural deformation during 15-20 tonne impact events common in gold mining operations.

| Manufacturer | Mesh Longevity (hours) | Throughput (tph) | Energy Efficiency | Price Range (USD) |

|---|---|---|---|---|

| MiningTech Pro | 8,200 | 450 | 0.38kW/t | $28,000-42,000 |

| GlobalSieve HD | 6,500 | 380 | 0.45kW/t | $19,500-35,000 |

| DuraScreen XR | 9,100 | 510 | 0.33kW/t | $34,500-48,000 |

Adaptable Engineering for Mineral Challenges

Modular designs enable rapid mesh configuration changes: transition from 3mm nickel mesh to 12mm polyurethane panels requires under 90 minutes. Customizable excitation forces (7-12kN) accommodate materials with bulk densities from 1.6-3.2 t/m³. Corrosion-resistant coatings extend service life by 60% in high-salinity coal processing environments.

Quantifiable Operational Improvements

Brazilian iron ore processors achieved 22% increased yield consistency after implementing AI-powered sieve monitoring systems. Canadian oil sands operations reduced replacement part costs by $17/tonne through optimized screen deck angles (18°-25° adjustment range). Automated tension balancing maintains ±0.03mm mesh alignment precision during continuous operation.

Cross-Industry Implementation Successes

Underground lithium mines improved material classification speed by 40% using dual-frequency (25/50Hz) screening modules. South African platinum operations extended maintenance intervals from 72 to 210 hours through laser-welded frame construction. Indonesian nickel processors reduced material carryover by 29% with 3D-printed mesh surfaces.

Securing Optimal Mining Sieve for Sale Solutions

Leading operations now demand sieves with ISO 9001:2015 certification and minimum 8,000-hour durability guarantees. Advanced models feature real-time mesh integrity monitoring through embedded strain gauges (±0.5% accuracy). Thermal imaging systems prevent 92% of potential bearing failures in continuous mining sieve applications.

(mining sieve for sale)

FAQS on mining sieve for sale

Q: Where can I find a high-quality mining sieve for sale?

A: High-quality mining sieves are available through industrial equipment suppliers, specialized mining machinery retailers, and online marketplaces like Alibaba or TradeKey. Ensure the supplier offers durable materials like stainless steel or polyurethane.

Q: What factors should I consider when buying mining screens for sale?

A: Key factors include mesh size, material durability (e.g., rubber or wire mesh), compatibility with your mining equipment, and resistance to abrasion or corrosion. Always verify supplier certifications and customer reviews.

Q: How do I maintain a sieve mining equipment for longevity?

A: Regularly clean the sieve to prevent material buildup, inspect for tears or deformities, and store it in a dry environment. Replace worn components like mesh panels or frame fasteners promptly.

Q: Are mining sieves for sale suitable for heavy-duty applications?

A: Yes, many mining sieves are designed for heavy-duty use, especially those made with reinforced steel or hybrid polymers. Check product specifications for load capacity and recommended operational environments.

Q: What is the price range for industrial-grade mining screens for sale?

A: Prices vary from $200 to $5,000+ depending on size, material, and customization. Bulk purchases or direct orders from manufacturers often reduce costs compared to third-party retailers.