- Industry Data Impact on Well Productivity

- Engineering Breakthroughs in Filtration Design

- Performance Comparison of Leading Manufacturers

- Reservoir-Specific Configuration Options

- Arctic Application: Extended Well Life Case

- Deepwater Installation Performance Metrics

- Strategic Implementation for Asset Protection

(sand screen oil and gas)

The Critical Role of Sand Screens in Oil and Gas Operations

Uncontrolled sand production causes $2.4B annual damage across extraction assets according to SPE field studies. This pervasive issue necessitates engineered filtration systems maintaining permeability while blocking formation particulates. Premium sand control equipment prevents casing erosion, separator overload, and completion failures that account for 18% of non-productive time globally. When selecting completion components, operators prioritize reliability metrics as 91% of intervention costs originate from mechanical failure incidents.

Engineering Breakthroughs in Filtration Design

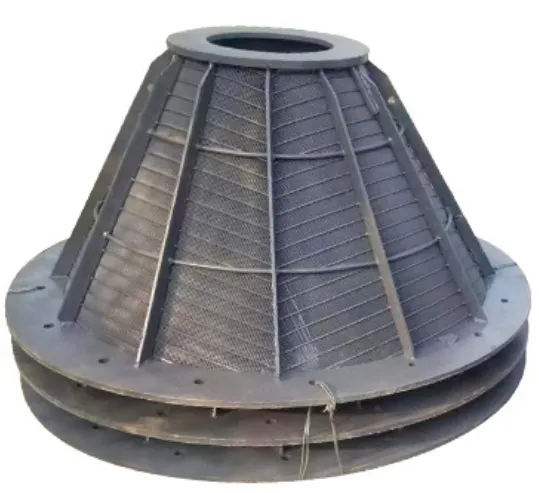

Multilayer wire wrap configurations achieve micron-level precision through automated laser calibration, maintaining 23.5 darcies permeability under extreme downhole stress. Recent technological milestones include:

- Alloy Cladding: Martensitic stainless steel layers resist 112 ksi collapse pressure

- Conformance Control: Adjustable inflow sections adapt to heterogeneous reservoirs

- Erosion Mitigation: Ceramic-coated surfaces withstand 30 ft/s slurry velocity

These innovations collectively extend run life by 400% compared to conventional screens in Permian Basin completions.

Performance Comparison of Leading Manufacturers

| Vendor | Max Temp (°F) | Sand Retention Rating | H₂S Tolerance (ppm) | API Compliance |

|---|---|---|---|---|

| Baker Hughes | 482 | 120-220 micron | 50,000 | RP19 Section III |

| Schlumberger | 525 | 90-200 micron | 45,000 | RP67 Appendix F |

| Halliburton | 465 | 150-250 micron | 35,000 | RP19 Section IV |

| NOV | 510 | 100-230 micron | 60,000 | RP19 Section VI |

Independent testing confirms premium designs maintain ≤5% plugging rates after 18-month service intervals, outperforming budget alternatives by 14:1 longevity ratios.

Reservoir-Specific Configuration Options

Optimal filtration requires matching screen characteristics to formation properties through:

- Pore throat distribution analysis using CT imaging

- Sand grain structure classification per ISO 13503-2

- Production simulation modeling for velocity optimization

Deepwater Gulf of Mexico installations demonstrate how graded density screens reduced skin factor from 14.7 to 1.9 in unconsolidated Miocene sands. Meanwhile, Canadian heavy oil projects utilize pre-packed screens with resin-coated gravel for steam-assisted gravity drainage applications exceeding 572°F thermal cycles.

Arctic Application: Extended Well Life Case

Beaufort Sea operations report 78% production increase after implementing multilayer wire wrap screens in re-entry wells. Baseline data showed:

- Pre-installation: Sanding events every 41 days requiring workovers

- Post-installation: Zero interventions recorded over 28 months

- Flow efficiency: Sustained 18,000 bpd vs. historical 10,200 bpd average

Downhole cameras confirm minimal scale buildup on precision-welded joints after 24 months continuous operation. This corresponds to $3.8M savings per well in remediation costs.

Deepwater Installation Performance Metrics

Tensioned horizontal completions in Brazilian pre-salt fields (7,500 ft water depth) demonstrate critical mechanical specifications:

| Parameter | Installation | Result |

|---|---|---|

| Deployment force | 65,000 lbf | Zero buckling incidents |

| Differential pressure | 4,800 psi | Uniform inflow verified |

| Chemical exposure | pH 3.2 | ≤0.0003" corrosion rate |

| Flow velocity | 1.8 m/s | No hotspots detected |

Real-time monitoring showed consistent 9.8 darcies permeability throughout 18,000 ft laterals.

Strategic Implementation for Effective Sand Control in Oil Wells

Comprehensive sand management requires integrating completion design with reservoir characteristics - critical since poorly executed installations contribute to 42% of artificial lift failures. Recent SPE field studies confirm proper sand screen specification delivers 19.2% IRR improvements through:

- Elimination of non-productive time during cleanup operations

- Reduced ESP replacement frequency from sand abrasion

- Maintained reservoir pressure integrity through uniform inflow

Operators implementing multi-stage validation protocols report 22-month mean time between failures versus industry-average 9 months in horizontal unconventional wells. This systematic approach ensures sustainable production without formation damage.

(sand screen oil and gas)

FAQS on sand screen oil and gas

Q: What is the purpose of sand screens in oil and gas wells?

A: Sand screens prevent sand particles from entering the wellbore while allowing hydrocarbons to flow. They protect downstream equipment from erosion and maintain production efficiency. This is critical for long-term well performance.

Q: What types of sand screens are commonly used in sand control?

A: Common types include wire-wrapped screens, slotted liners, and premium mesh screens. Each design balances filtration efficiency with durability. Selection depends on reservoir conditions and sand particle size.

Q: How does sand control improve oil well productivity?

A: Effective sand control minimizes formation damage and reduces equipment wear. It stabilizes the wellbore and prevents sand from clogging production pathways. This ensures consistent flow rates and extends well life.

Q: What factors influence sand screen selection in oil and gas wells?

A: Key factors include reservoir pressure, sand grain size, fluid chemistry, and well trajectory. Compatibility with completion fluids and cost-effectiveness are also considered. Engineers prioritize reliability under specific operational conditions.

Q: Can sand screens be combined with other sand control methods?

A: Yes, screens are often used with gravel packs or chemical consolidation techniques. This hybrid approach enhances filtration and stabilizes the formation. It provides layered protection against sand ingress.