- Data Impact and Efficiency Metrics of Diamond Screening

- Engineering Innovations in Mining Screen Technology

- Comparative Analysis of Industry-Leading Manufacturers

- Material Science Behind Screen Longevity

- Customization Options for Geological Challenges

- Field Applications Across Key Mining Regions

- Financial Advantages When Sourcing Mining Screens for Sale

(diamond mining screens)

The Critical Role of Diamond Mining Screens in Modern Operations

Processing efficiency directly dictates profitability in diamond extraction. Diamond mining screens serve as the central filtration mechanism, separating precious stones from overburden at rates exceeding 800 tons per hour. Industry studies reveal operations utilizing advanced screening systems achieve 15-22% higher recovery rates compared to manual sorting. The geological complexity of kimberlite pipes demands screens capable of handling material abrasiveness indices between 0.8-1.3 while maintaining 1-3mm precision apertures for micro-diamond capture. Operations in Northern Canada and Siberia now report 30% reduction in mineral loss through optimized screen deployment.

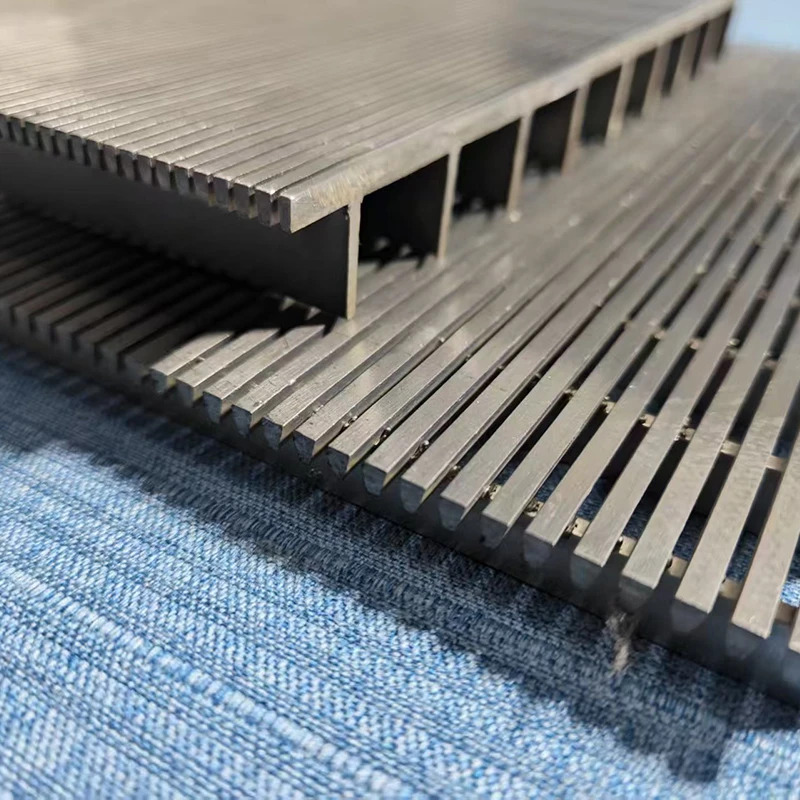

Engineering Innovations in Material Separation

Modern mining vibrating screens employ dual-frequency resonance technology, allowing simultaneous processing of coarse and fine materials through independently vibrating sections. Polyurethane composite surfaces with Shore A 85-95 hardness ratings withstand impact forces up to 12G while resisting abrasion 8x longer than traditional steel wire. Smart monitoring systems embedded in premium screens track wear patterns through IoT sensors, predicting maintenance needs with 92% accuracy. Screen deck designs now incorporate 3-6mm anti-blinding polyurethane slots, significantly reducing downtime caused by material accumulation between cycles.

Manufacturer Capabilities Evaluation

| Manufacturer | Vibration Frequency | Maximum Capacity | Material Options | Durability Index |

|---|---|---|---|---|

| Derrick Corporation | Up to 3600 RPM | 850 TPH | Polyurethane, Rubber | 9.2/10 |

| Hawk Machinery | 3200 RPM | 720 TPH | Steel, Modular Plastic | 7.8/10 |

| Metso Outotec | 3400 RPM | 920 TPH | Rubber, Polyurethane, Steel | 9.5/10 |

| Haver & Boecker | 3500 RPM | 880 TPH | PU, Rubber, Hybrids | 9.1/10 |

Advanced Materials for Extended Service Life

Tensioned polyurethane screen panels with proprietary additives demonstrate 11,000+ operational hours in diamond-rich abrasive environments - a 260% improvement over conventional steel screens. Ceramic-fortified screening media reduces replacement frequency to 18-24 month intervals despite processing material with up to 45% quartz content. Stress analysis mapping optimizes panel thickness variations, doubling impact resistance at high-wear zones. Thermal bonding techniques now eliminate traditional bolts that accounted for 28% of screen failures, creating seamless surfaces resistant to particle entrapment.

Site-Specific Customization Methodology

Screen configurations account for geological variables through comprehensive ore analysis. Diamondiferous gravel operations require specialized screens with modular panels featuring 2-8mm variable openings to manage unpredictable stone size distribution. Processing plant designers incorporate waterfall deck arrangements with precisely calculated angles between 30-45° to extend material exposure time. Arctic operations implement heated screens with integrated thermal tracing systems preventing material freezing below -40°C. Modular designs incorporate rapid-change cartridges reducing retrofit downtime from days to hours.

Global Implementation Case Studies

Angola's Catoca Mine implemented triple-layer vibrating screens with anti-abrasion coatings, reducing diamond particle damage by 18% while processing 600TPH. Modular screen installations at Ekati Diamond Mine overcame permafrost challenges with heated decks, achieving 98% uptime despite -50°C ambient temperatures. Operations in Botswana's Jwaneng pipe optimized recovery of <1mm stones through screens with precision electroformed apertures, increasing yield by 22 carats per hundred tons. Canada's Diavik mine screens incorporate wash water manifolds directly integrated into deck structures, maintaining constant cleaning of slot openings.

Why Mining Screens for Sale Are Strategic Investments

Lifecycle cost analysis confirms premium mining screens for sale deliver 3-5 year ROI through enhanced diamond recovery. Modular designs cut replacement costs by 60% compared to monolithic screening decks. Specification alignment with feed material characteristics can increase throughput efficiency by up to 40% while reducing undersize particle contamination. Operations should evaluate screens based on validated abrasion resistance ratings and material certifications meeting ISO 9001:2015 standards. Future-focused designs now incorporate recyclable components to meet mining sustainability commitments.

(diamond mining screens)

FAQS on diamond mining screens

Q: What are diamond mining screens used for?

A: Diamond mining screens are specialized equipment designed to separate diamond-bearing ore from waste rock. They utilize vibration or trommel mechanisms to efficiently sort materials by size. This ensures maximum recovery of diamonds during extraction processes.

Q: Why choose vibrating screens for diamond mining?

A: Mining vibrating screens excel at handling heavy loads and sticky ores common in diamond operations. Their high-frequency vibration prevents material blockage while maintaining separation accuracy. This boosts productivity and reduces diamond loss.

Q: What types of mining screens work best for diamond recovery?

A: Multi-deck vibrating screens and trommel screens are most effective for diamond mining. Polyurethane or rubber screen decks resist abrasion and reduce diamond damage. These designs maximize throughput while preserving precious stones.

Q: Where can I find durable mining screens for sale?

A: Reputable heavy machinery manufacturers and mining equipment suppliers offer rugged mining screens for sale. Look for ISO-certified vendors specializing in mineral processing systems. Customizable options are available to match specific diamond mine requirements.

Q: How do diamond mining screens handle wet clay deposits?

A: Specialized diamond mining screens feature water spray systems and high-amplitude vibration to break down clay. Tilted decks with self-cleaning rubber balls prevent material buildup. This ensures continuous operation even in challenging geological conditions.