- Introduction to hydrocarbon production challenges

- The financial impact of sand intrusion

- Core technological approaches to sand management

- Industry solution comparison matrix

- Custom engineering for reservoir-specific challenges

- Field implementation case studies

- Future outlook for wellbore integrity

(sand control in oil well)

Understanding sand control in oil well

operations

Unmanaged sand production remains one of the most persistent challenges in hydrocarbon extraction, causing operational disruptions across global basins. Effective sand control in oil and gas wells requires engineered solutions that prevent formation sand migration while preserving well productivity. As reservoirs age and production techniques evolve, the industry continues developing advanced sand screen oil and gas technologies capable of maintaining flow efficiency under increasingly demanding downhole environments. The fundamentals involve creating mechanical or chemical barriers that filter formation solids without significant pressure drops.

The financial impact of sand intrusion

Operational data reveals the severe consequences of inadequate sand management. According to field reports from the Permian Basin, average well downtime caused by sand-related issues exceeds 120 hours annually, resulting in production losses valued at $2.3-3.8 million per well. The cumulative industry cost of sand damage surpasses $10 billion yearly when accounting for equipment erosion, cleanout operations, and lost productivity. Recent case studies show:

- ESD (Electrical Submersible Pump) replacements increase by 300% in wells with sand breakthrough

- Unplanned workovers add $500,000-750,000 per incident

- Facility maintenance costs rise by 40% due to separator and pipeline abrasion

With offshore wells demonstrating even greater financial exposure, these figures underscore the critical ROI of robust sand control in oil and gas wells infrastructure.

Core technological approaches to sand management

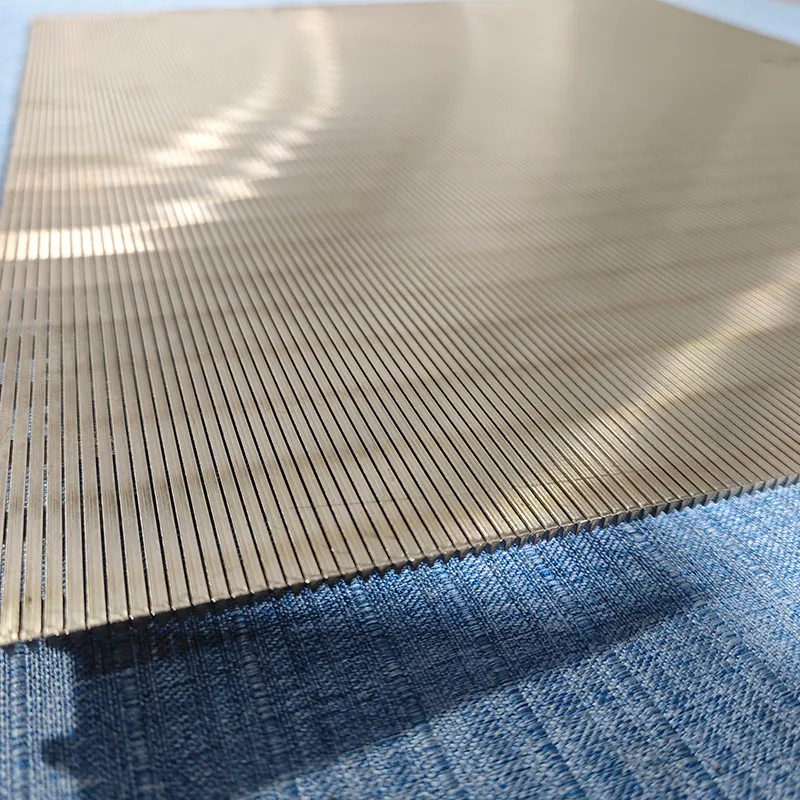

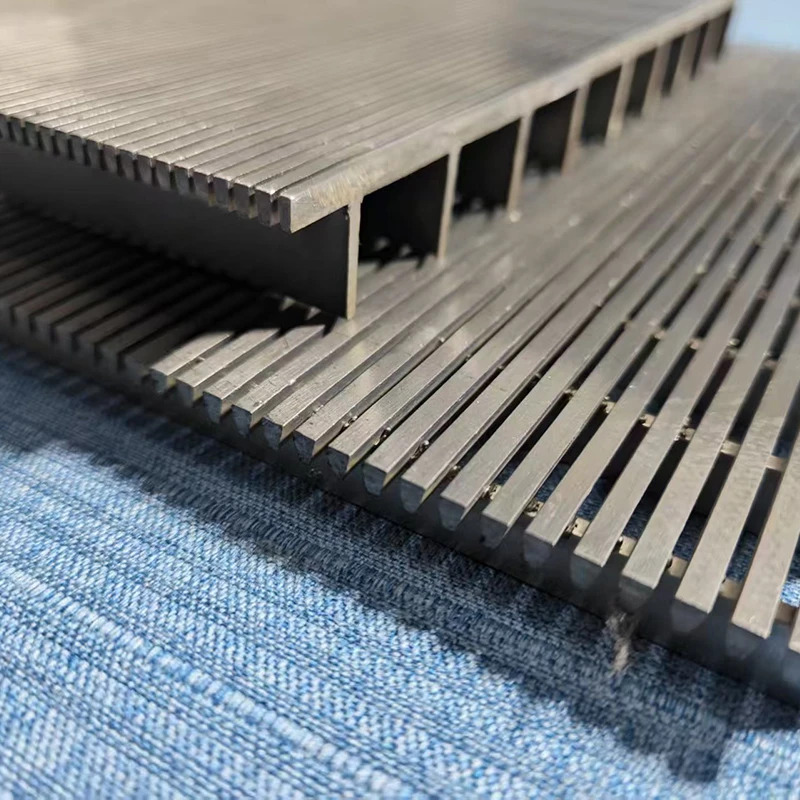

Modern sand screen oil and gas systems leverage material science innovations to address distinct reservoir challenges. Premium wire-wrap screens deliver filtration accuracy down to 150 microns using corrosion-resistant alloys, with multi-layered mesh designs improving particle retention by 65% over traditional slotted liners. Gravel pack solutions achieve >95% success rates in vertical completions, while advanced chemical consolidation treatments expand options in complex well trajectories. Recent technological improvements include:

- Shape-memory polymer coatings that self-conform to borehole irregularities

- Nanocomposite filter media resistant to erosion at flow velocities above 5 ft/sec

- Real-time monitoring systems detecting sand concentrations below 0.1% volume

These innovations significantly extend equipment service life while reducing maintenance frequency and non-productive time.

Industry solution comparison matrix

| Solution Type | Sand Retention Capacity | Installation Complexity | Operational Lifetime | Upfront Cost | Best Application |

|---|---|---|---|---|---|

| Slotted Liners | Low | Simple | 2-4 years | $120K/well | Tight budget projects |

| Wire-Wrap Screens | High | Moderate | 5-8 years | $185K/well | Horizontal unconventional |

| Premium Mesh Screens | Very High | Complex | 8-12 years | $260K/well | Deepwater wells |

| Open-Hole Gravel Packs | Extreme | High | 15+ years | $400K/well | Offshore developments |

Custom engineering for reservoir-specific challenges

Optimization of sand control in oil well applications requires tailoring solutions to localized geomechanical conditions. Reservoir engineers integrate multiple datasets including particle size distribution, flow rate projections, and completion design to specify appropriate filtration parameters. For high-permeability formations exhibiting fines migration, multilayer mesh configurations prevent bridging while maintaining permeability above 150 darcies. In wells with CO2 injection considerations, operators utilize chromium-based alloys that withstand acidic environments. Recent advances include:

- Adaptive inflow control devices regulating flow velocity to sub-erosion thresholds

- Expandable screen technology eliminating annular space in sidetracks

- Intelligent gravel packing methods achieving 92% annular fill efficiency

Field implementation case studies

Case 1: An operator in the Gulf of Mexico deployed ceramic sand screens in a high-temperature (320°F) sour gas application with prior history of premature failures. Despite challenging H2S concentrations exceeding 20%, the redesigned system has maintained sand-free production at 85 MMCFD for 34 months, reducing completion failures by 76% compared to offset wells.

Case 2: Onshore Alberta, an operator implemented multilayer mesh screens across a heavy oil field with significant fines production. Initial results demonstrate elimination of workover frequency, while sustaining 98% uptime over 24 months. Sand monitoring equipment shows particulate production below detectable levels (<0.005% by volume) despite tripling the initial fluid withdrawal rates.

Future outlook for sand control in oil and gas wells

The evolution of sand screen oil and gas technology continues focusing on reliability enhancement through material science innovations and predictive analytics. Major service providers are developing integrated downhole sensing systems capable of real-time sand detection and adaptive flow control, with field trials showing 40% reduction in remediation costs. As operators pursue reserves in deeper, hotter formations, next-generation screens will incorporate advanced ceramics and nanostructured composites engineered to withstand temperatures exceeding 500°F while maintaining filtration integrity throughout extended production cycles.

(sand control in oil well)