- Factors influencing vibrating screen pricing structures

- Technical breakthroughs driving cost-efficiency

- Manufacturer comparison matrix: Specifications vs pricing

- Customizable solutions for budget optimization

- Industry-specific screen selection scenarios

- Installation/maintenance impact on operational costs

- Industry benchmarks: Application case studies

(vibrating screen price)

Key Determinants in Screening Equipment Investment

Industrial screening equipment represents significant operational investments where vibrating screen price

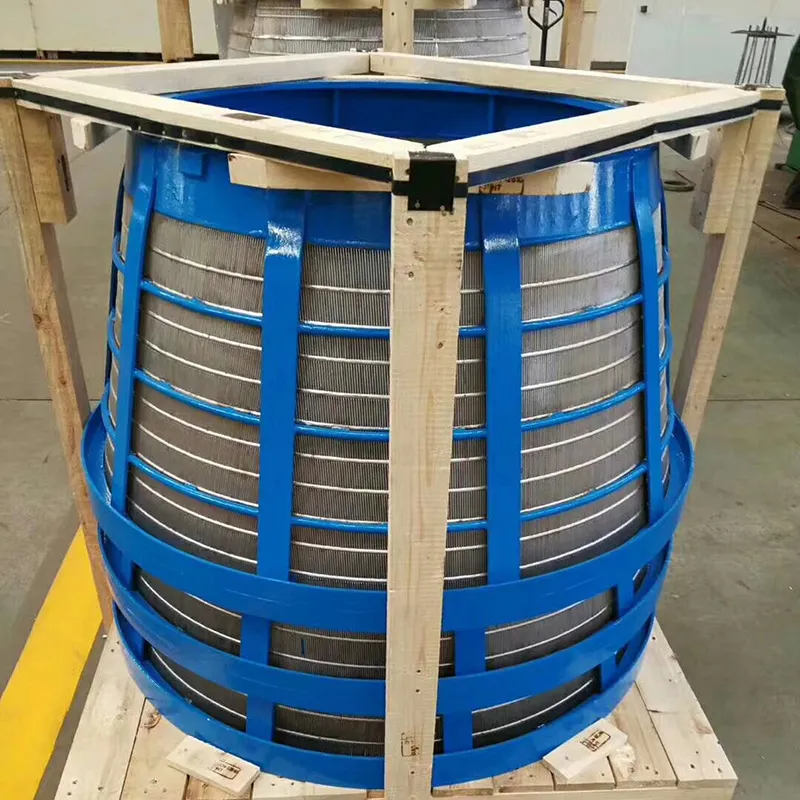

reflects multiple engineering considerations. Material composition directly impacts manufacturing costs, with stainless steel well screen variants commanding 25-40% premiums over carbon steel equivalents. Production volume requirements dictate deck configurations, where single-layer models average $12,500-$35,000 while triple-deck units reach $85,000+. Additional cost factors include motor power (5-50HP models ranging $1,200-$8,500), screening media options (polyurethane panels at $800 vs wedge wire decks at $4,500), and seismic reinforcement needs for installations above ground level. Industry reports indicate screening equipment typically consumes 7-12% of mineral processing capital expenditure, demanding precise technical alignment with operational parameters.

Engineering Innovations Reducing Operational Expenditure

Modern screening solutions integrate material science breakthroughs that enhance longevity while controlling vibrating screen price. Laser-cut perforated stainless steel decks demonstrate 23% longer service life than stamped alternatives according to ASTM E8 tests, reducing replacement costs by $7,800 annually for continuous operations. Direct-drive eccentric mechanisms eliminate gearbox failures that previously caused 38% of unscheduled downtime. Advanced polymers in Coanda screens achieve 0.5mm separation accuracy with water consumption reduced to 3m³/ton – 70% less than conventional alternatives. These innovations maintain competitive stainless steel well screen price structures while delivering 18-month ROI through energy savings and maintenance reduction.

| Manufacturer | Base Price Range | Deck Options | Motor Efficiency | Lifetime Cost/TPH |

|---|---|---|---|---|

| Metso Premier | $28,000-$62,000 | 1-4 decks | 92% IE3 standard | $0.23 |

| Sandvik Heavy-Duty | $35,500-$78,000 | 2-5 decks | 94% IE4 premium | $0.31 |

| Derrick Corporation | $22,400-$48,000 | 1-3 decks | 89% IE2 standard | $0.27 |

| HAWK SuperScreen | $19,800-$44,500 | 1-4 decks | 90% IE3 standard | $0.21 |

Tailored Screening Solutions for Diverse Budgets

Leading manufacturers now offer tiered pricing strategies to accommodate varying financial constraints while maintaining performance standards. Modular designs enable 15-30% savings through component-level customization where clients select specific drive mechanisms ($3,200-$7,500 options), frame reinforcements ($950-$4,200), and screening surfaces. Coanda screen price packages include waterfall upgrades for sticky materials at $9,500 additions, while corrosion-resistant enhancements for stainless steel well screen variants add $6,800-$14,000 depending on alloy grades. Budget-focused operations frequently deploy phased implementation, installing basic $16,500 systems then adding $7,200 automation packages during operational expansions.

Practical Screening Application Environments

Material characteristics decisively influence appropriate screen selection and corresponding cost structures. Abrasive granite operations require $38,000+ heavy-duty units with tungsten carbide-coated decks, while pharmaceutical applications implement $52,000 sanitary stainless steel well screens meeting FDA 21 CFR Part 11 standards. Water management districts increasingly adopt Coanda screen technology at $27,500 average pricing for river intake facilities, reporting 0.25mm separation precision without moving parts. Agricultural processors utilize $21,000 vibration systems with FDA-compliant screens for grain sorting, while recycling plants invest in $44,000 abrasion-resistant trommels for MSW processing.

Operational Economics Beyond Initial Purchase

Comprehensive cost assessment extends beyond initial vibrating screen price to include installation, operational, and maintenance expenditures. Foundation preparation adds $4,800-$15,000 depending on seismic requirements, while dust containment systems average $7,200 additional investment. Energy analysis reveals premium motors reduce kWh/ton consumption by 18-22%, yielding $3,100 annual savings at 24/7 operations. Preventative maintenance programs ($1,200-$4,500 annually) demonstrate 11-month payback periods by reducing unscheduled downtime by 73%. These secondary costs substantially impact lifetime value calculations across all screen variants.

Performance Validation Through Industry Deployment

Field data substantiates the economic justification for contemporary screening investments within operational budgets. A Nevada gold operation documented 22% increased throughput after upgrading to a $68,000 triple-deck vibrating screen while reducing energy consumption by 31% compared to their legacy system. Municipal water authorities report 90% reduction in intake maintenance costs since installing stainless steel well screen filters priced at $185 per square foot of screening surface. Aggregate producers utilizing Coanda screens validate claims of 95% separation efficiency at 12% lower operating costs than traditional alternatives. These documented outcomes demonstrate optimized life cycle costs despite initial vibrating screen price considerations, with quarry operations typically achieving ROI within 14 operational months.

(vibrating screen price)

FAQS on vibrating screen price

下面是根据核心关键词创建的5组英文FAQ问答,使用HTML富文本格式:Q: What factors influence the vibrating screen price?

A: Vibrating screen prices vary by size, material grade, and motor power. Custom designs and durability features like corrosion resistance may increase costs. Request a detailed quote for precise pricing.

Q: How much does a stainless steel well screen cost?

A: Stainless steel well screen prices range from $500-$5,000+ depending on aperture size and alloy grade. Higher 316L stainless steel costs more but offers superior corrosion resistance. Slot configurations and diameter also affect pricing.

Q: Why choose Coanda screens over traditional vibrating screens?

A: Coanda screens are valued for water treatment efficiency with zero moving parts. Though initially pricier ($8k-$25k), they reduce long-term maintenance costs. They’re ideal for fine-particle separation in wastewater plants.

Q: Are budget vibrating screens reliable for industrial use?

A: Budget screens ($1k-$5k) suit light-duty applications but often lack durability. Industrial-grade units feature reinforced frames and wear-resistant meshes for longevity. Always verify load capacity and warranty terms when comparing prices.

Q: Where can I get competitive quotes for all three screen types?

A: Request quotes directly from manufacturers like Metso or GN Separation. Specify requirements: flow rate (Coanda screens), slot size (stainless screens), or G-force (vibrating models). Bulk orders typically include 10-15% discounts.