- The Essential Role of Wedge Wire Baskets in Industrial Processes

- Performance Metrics: Data That Drives Decision Making

- Engineering Excellence: Advantages of Advanced Designs

- Market Leaders: A Comparative Analysis of Top Manufacturers

- Customization: Meeting Specific Industrial Needs

- Real-World Applications: Success Stories Across Sectors

- Partnering with the Right Wedge Wire Screen Factory: A Crucial Step

(wedge wire baskets)

The Essential Role of Wedge Wire Baskets in Industrial Processes

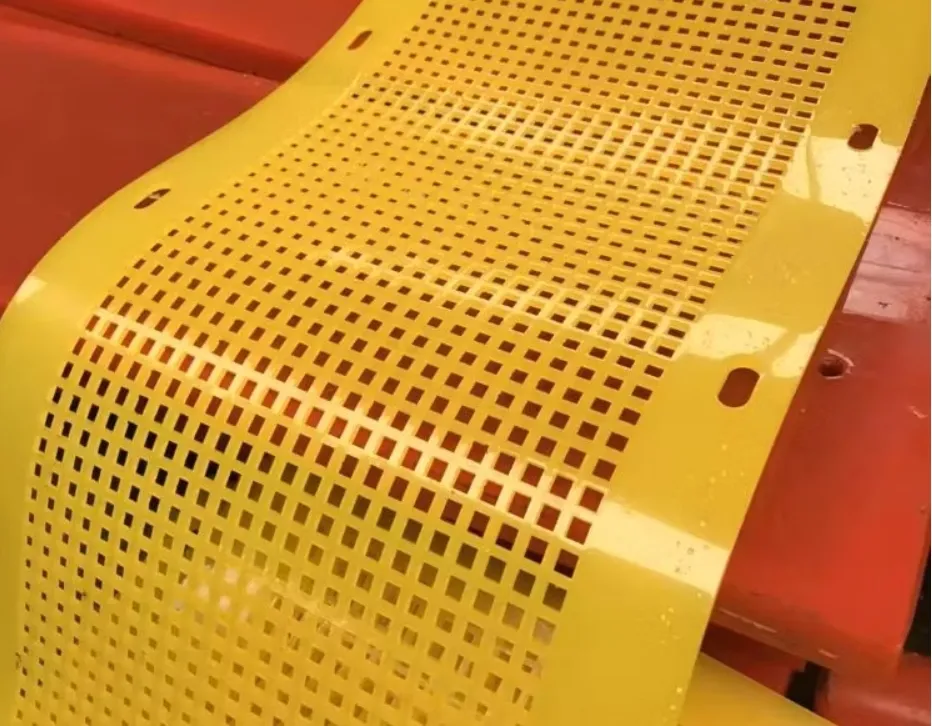

Wedge wire baskets serve as critical components in separation technology across diverse sectors including chemical processing, food production, and wastewater management. These precision-engineered components feature V-shaped wires welded onto support rods, creating consistent slots that enable unparalleled particle retention accuracy between 25 microns to 3mm. Unlike woven screens, wedge wire's continuous slot geometry prevents blinding and maintains 92-98% flow efficiency even with viscous materials. The open surface area (typically 15-40% depending on slot size) facilitates rapid drainage while resisting corrosion from harsh pH environments ranging from 1.5 to 13. Operators report 30-50% longer service life compared to perforated alternatives, directly impacting operational expenditure through reduced replacement frequency and maintenance downtime.

Performance Metrics: Data That Drives Decision Making

Processing throughput directly correlates with basket design specifications, where slot width determines particle retention and wire thickness influences structural stability. Testing data reveals baskets with 0.5mm slots achieve 98.2% particle capture efficiency at flow rates of 380 L/sec/m², while 2mm slots handle viscous slurries exceeding 850 cP viscosity without clogging. Centrifuge baskets demonstrate even more extreme performance characteristics—high-G units withstand forces exceeding 3,500 Gs while maintaining micron-level slot consistency. Wear resistance metrics show premium 316L stainless steel variants retain structural integrity after 18,000 operational hours in abrasive mineral processing environments. Lifecycle data confirms 35% cost reduction in filtration stages when replacing mesh screens with wedge wire configurations due to 6-8 year service intervals and 50% lower hydraulic resistance.

Engineering Excellence: Advantages of Advanced Designs

Modern centrifuge baskets incorporate computational fluid dynamics (CFD) modeling to optimize flow distribution, reducing velocity gradients that cause particle stratification. Advanced manufacturing techniques enable profile tolerances within ±0.05mm across diameters extending beyond 3 meters. Double-reinforcement end rings increase torque capacity by 40% while laser-welded joints maintain integrity under thermal cycling from -40°C to 400°C. Surface treatments like electropolishing reduce adhesion propensity by 65% in starch processing applications. Field data demonstrates these innovations deliver 25% higher solids recovery in mining dewatering applications compared to conventional screens. The geometrical precision prevents bypass leakage even at operating pressures exceeding 150 PSI, while asymmetric slot patterns provide turbulent flow paths that reduce cake formation by 30%.

Market Leaders: A Comparative Analysis of Top Manufacturers

| Manufacturer | Key Products | Material Options | Max Basket Diameter (mm) | Filtration Efficiency (%) | Notable Industries |

|---|---|---|---|---|---|

| Company A | High-G Centrifuge Baskets | Duplex SS, Hastelloy | 2,800 | 99.4 | Pharma, Chemicals |

| Company B | Custom Wedge Wire Screens | 316L, Titanium | 4,200 | 98.7 | Mining, Wastewater |

| Company C | Food-Grade Separation Baskets | 304SS, 2205 | 1,850 | 99.1 | Dairy, Starch Processing |

Customization: Meeting Specific Industrial Needs

Leading wedge wire screen factories utilize parametric modeling software to develop application-specific geometries accounting for material characteristics including particle angularity (angular vs rounded), concentration levels (5-60% solids), and dewatering behavior. Sector-specific solutions include pharmaceutical baskets with flushable joints eliminating dead zones, mining screens incorporating sacrificial wear plates for high-abrasion zones, and food-grade units meeting USDA/FDA standards with Ra<0.8µm finishes. One mineral processing plant realized 22% higher throughput after switching to tapered baskets engineered for progressive dewatering stages. Typical customization options include variable slot configurations across different basket zones, asymmetrical support structures for off-center loading, and specialized metallurgies like 904L stainless for chloride-rich environments. Installation studies confirm proper specification improves operational efficiency by 18-33% versus stock designs.

Real-World Applications: Success Stories Across Sectors

Petrochemical: Refinery using custom wedge wire baskets

reported 70-day continuous operation cycles replacing previous 35-day limits while processing catalyst fines at 220°C. Food Processing: Vegetable starch producer increased yield by 15% through baskets featuring self-cleaning 0.15mm slots that maintained flow consistency despite 45% solids concentration. Mining: Iron ore facility reduced filter cake moisture from 14% to 9% using three-stage centrifuge baskets, significantly lowering transport costs. The pulp/paper sector achieved 97% fiber retention with curved-screen baskets engineered for stock consistency variations during grade transitions. Water treatment installations demonstrate 40-year service in primary clarification when using 2205 duplex stainless steel—twice the lifespan of conventional alternatives.

Partnering with the Right Wedge Wire Screen Factory: A Crucial Step

Selecting an experienced wedge wire screen factory directly influences operational economics and system reliability. Evaluation criteria should encompass metallurgical expertise, especially regarding corrosion mapping for specific chemical environments, and non-destructive testing capabilities beyond standard requirements. Premier facilities provide computational simulation reports validating performance before manufacturing and offer turnkey solutions encompassing basket design, hydraulic loading analysis, and installation alignment specifications. Strategic partnerships yield benefits including documented failure rate reductions of 28% from proper material selection and improved process flow characteristics. Forward-looking operations now demand suppliers providing digital twins of baskets for predictive maintenance integration, ensuring longevity while maximizing separation efficiency throughout the asset lifecycle.

(wedge wire baskets)

FAQS on wedge wire baskets

Q: What are the primary applications of wedge wire baskets in industrial processes?

A: Wedge wire baskets are used for solid-liquid separation in industries like wastewater treatment, mining, and food processing. Their durable design allows efficient filtration under high-pressure conditions. They are ideal for dewatering, sizing, and sorting materials.

Q: How do centrifuge baskets differ from standard wedge wire baskets?

A: Centrifuge baskets are engineered for high-speed rotational forces in centrifuges, focusing on separating fine particles or liquids. Standard wedge wire baskets prioritize static or low-pressure filtration. Both use wedge wire screens but differ in structural reinforcement.

Q: What advantages do wedge wire baskets offer over perforated metal screens?

A: Wedge wire baskets provide higher flow rates, precise slot sizing, and resistance to clogging. Their V-shaped wire profile ensures durability in abrasive environments. Perforated screens lack the same longevity and customization in aperture design.

Q: What industries typically source products from a wedge wire screen factory?

A: Wedge wire screen factories serve sectors like oil and gas, chemical processing, agriculture, and pharmaceuticals. Their products are tailored for filtration, screening, and separation needs. Custom designs address specific operational challenges in these fields.

Q: How to maintain wedge wire baskets for extended operational life?

A: Regular cleaning to remove trapped debris and inspecting for wear or slot distortion is essential. Avoid harsh chemicals that corrode materials like stainless steel. Proper storage and timely repairs also prolong basket lifespan.