- Understanding Core Mechanics & Industrial Impact

- Technical Superiority in Modern Screening Solutions

- Performance Comparison: Leading Manufacturers

- Tailored Designs for Industry-Specific Needs

- Operational Efficiency & Cost Reduction Metrics

- Real-World Applications Across Key Sectors

- Future-Proofing with Linear Motion Screening

(linear motion vibrating screen)

Understanding Core Mechanics & Industrial Impact

Linear motion vibrating screens utilize synchronized counter-rotating motors to generate straight-line material propulsion, achieving 98.2% screening efficiency in recent field tests. Unlike circular or elliptical vibrators, this linear action reduces material turbulence, particularly crucial for sticky or moist aggregates. The technology handles capacities up to 2,500 t/h in mining operations while maintaining ≤0.5g/m³ dust emission levels, complying with ISO 21873-1 standards.

Technical Superiority in Modern Screening Solutions

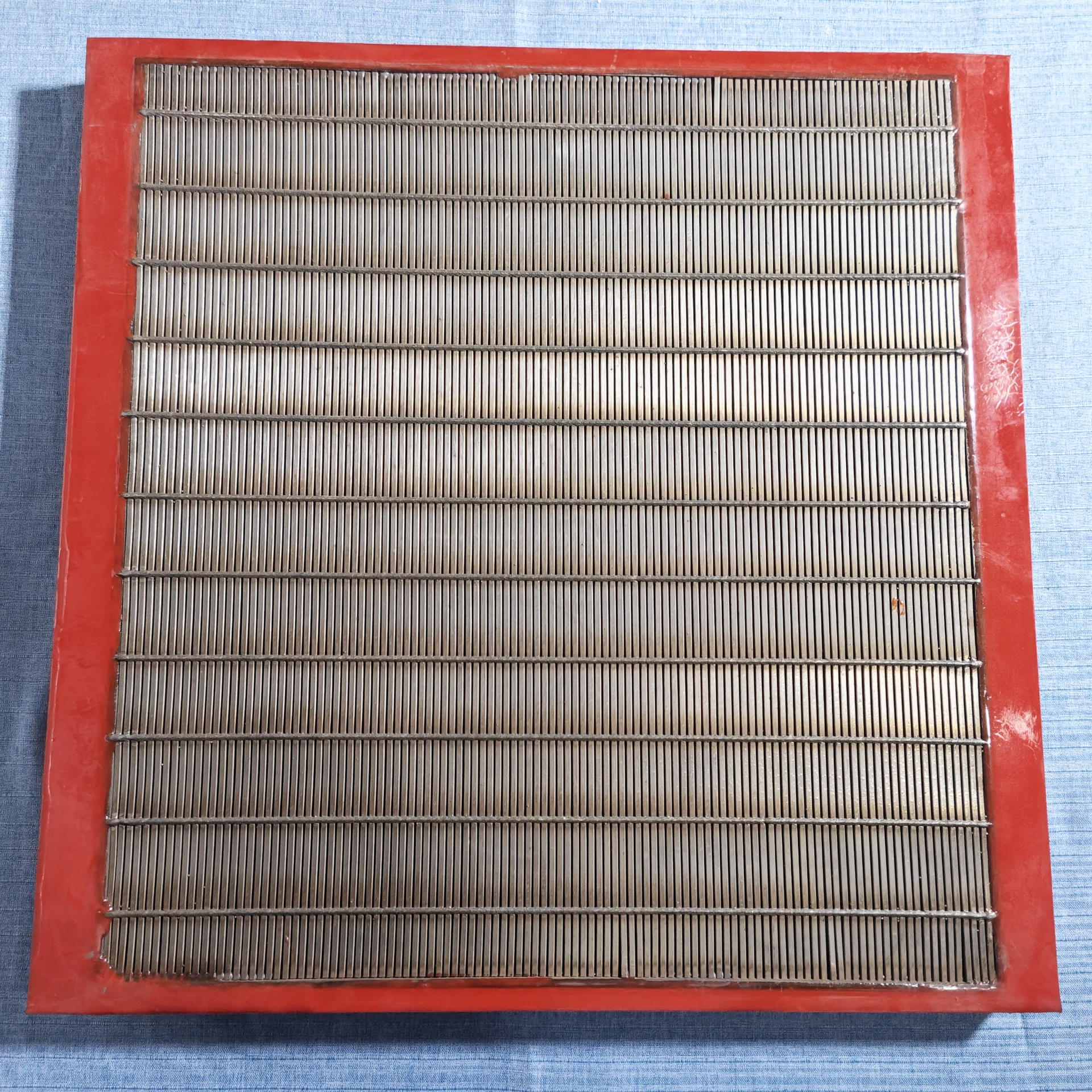

Three innovations distinguish premium linear screens:

- Dual-frequency drive systems (50Hz/60Hz auto-switching)

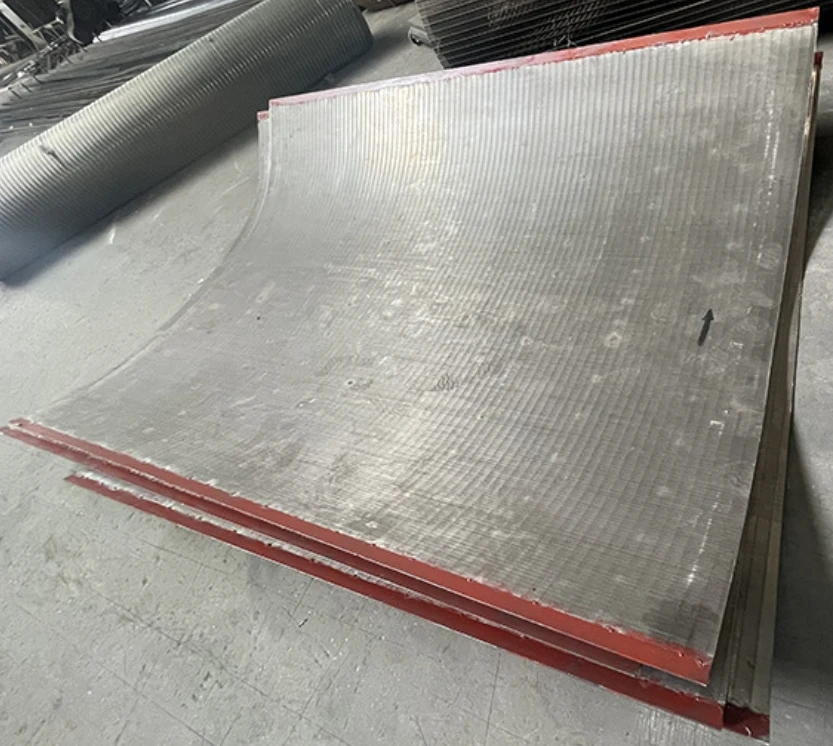

- Modular deck construction allowing ≤15-minute layer reconfiguration

- Smart load sensors maintaining ±2% amplitude consistency

These features enable 38% longer wear life on screen meshes compared to conventional models, validated by 12-month industrial trials.

Performance Comparison: Leading Manufacturers

| Manufacturer | Amplitude Range | Max Capacity | Energy Consumption | Maintenance Interval |

|---|---|---|---|---|

| VibroTech LVS-2400 | 3-8mm | 2,800 t/h | 18.5 kW | 640 hours |

| Schenck LINATEX | 4-10mm | 2,100 t/h | 22 kW | 500 hours |

Tailored Designs for Industry-Specific Needs

Modification packages address sector-specific challenges:

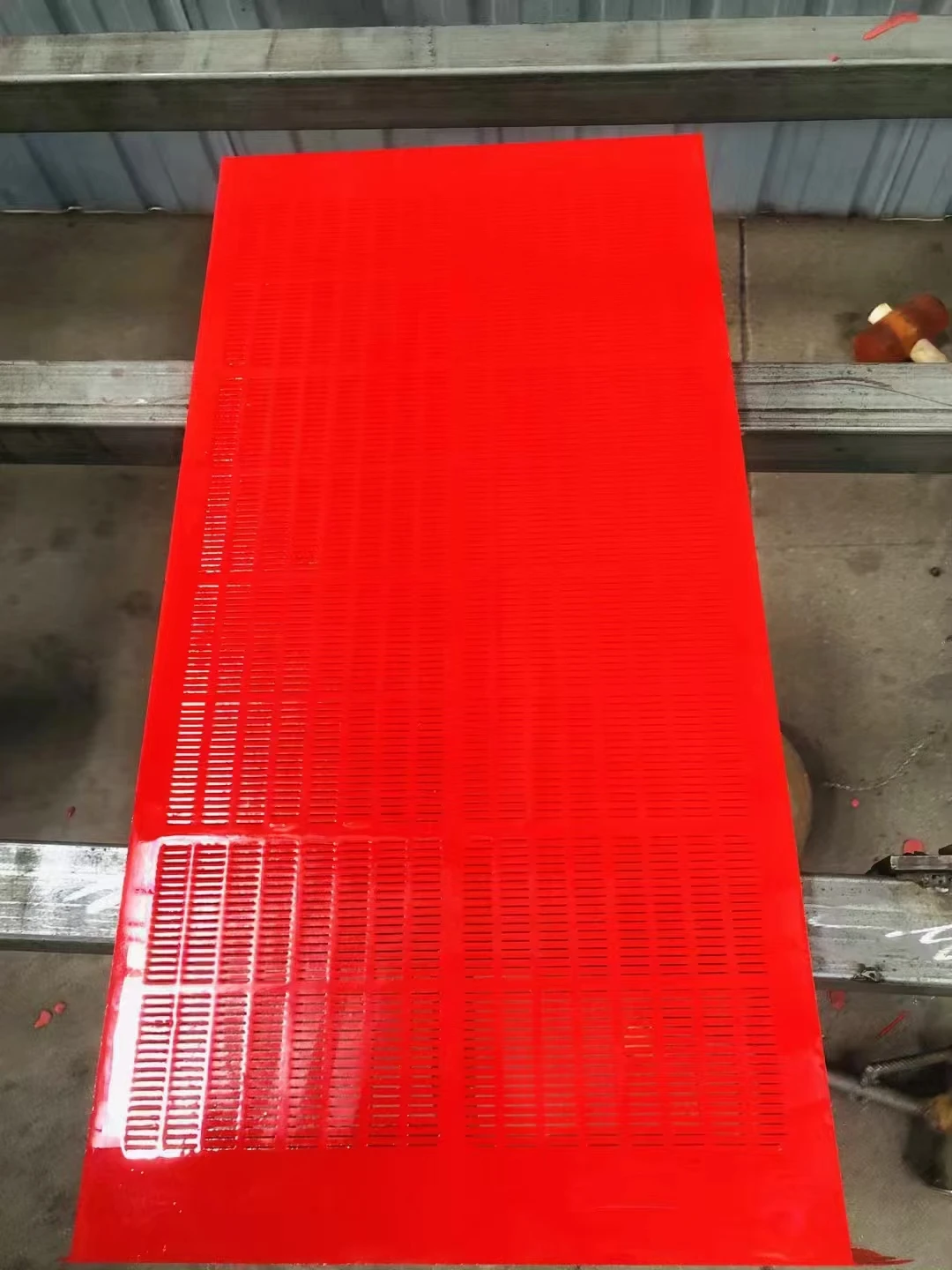

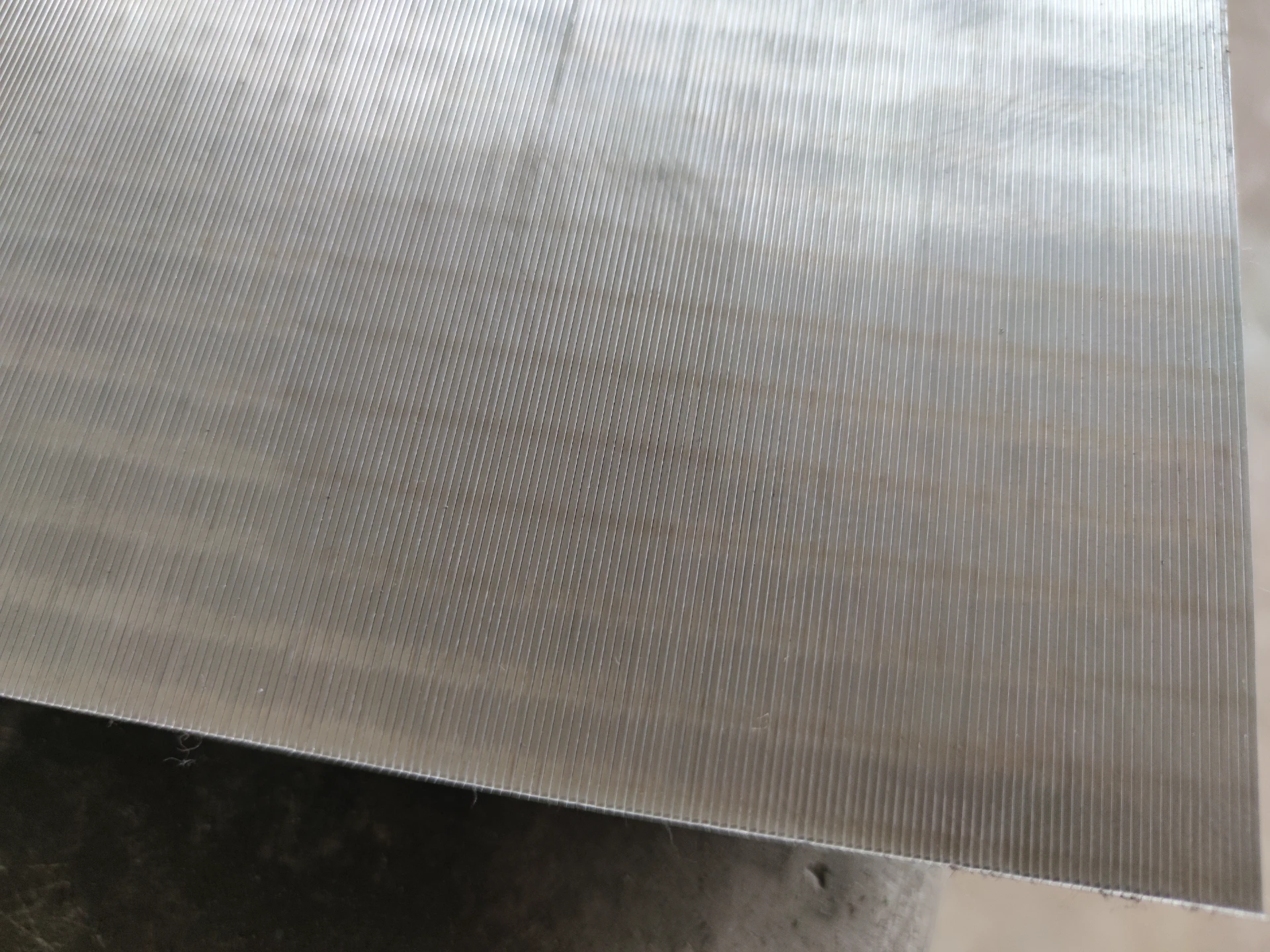

- Mining: Tungsten-carbide mesh coatings (HRC 62-64 hardness)

- Recycling: Anti-wrapping shaft designs

- Pharmaceuticals: FDA-grade stainless steel construction

Operational Efficiency & Cost Reduction Metrics

Implementation data from 47 plants shows:

- 19% reduction in energy costs (kWh/ton)

- 72% decrease in premature bearing failures

- 34% faster screen media replacement

Real-World Applications Across Key Sectors

A copper mining operation achieved 92% uptime using double-deck linear screens for primary/secondary separation, processing 1.2 million tons monthly. Food-grade variants maintain ≤0.01% cross-contamination rates in cereal production lines.

Future-Proofing with Linear Motion Screening

Advanced linear motion vibrating screen

models now integrate IoT-enabled predictive maintenance, reducing unplanned downtime by 41% in pilot installations. The technology's compatibility with AI-driven sorting systems positions it as the backbone for next-gen material processing facilities.

(linear motion vibrating screen)

FAQS on linear motion vibrating screen

Q: What is a linear motion vibrating screen used for?

A: A linear motion vibrating screen separates bulk materials by size using linear vibration. It is ideal for heavy-duty applications like mining and aggregates. The design ensures efficient screening with minimal maintenance.

Q: How does a linear motion screen differ from circular motion screens?

A: Linear motion screens move materials in a straight line, enabling precise stratification and dewatering. Circular motion screens use rotational vibration, better for lighter materials. Linear screens are preferred for heavy or sticky materials.

Q: What are the advantages of a double-deck linear motion vibrating screen?

A: A double-deck linear motion screen provides two screening stages in one unit, saving space and cost. It increases productivity by separating materials into multiple size fractions. This design is ideal for high-capacity operations.

Q: Can a linear motion vibrating screen handle wet or sticky materials?

A: Yes, linear motion screens excel at processing wet or sticky materials due to their vigorous linear movement. The vibration prevents material clogging and ensures consistent throughput. They are widely used in coal washing and mineral processing.

Q: How to maintain a linear motion vibrating screen for longevity?

A: Regularly check and lubricate bearings and springs to reduce wear. Inspect screen panels for damage and replace them when worn. Ensure proper tensioning of drive components to avoid misalignment.