- Introduction to Wedge Wire Screens and Industry Relevance

- Impact of Precise Screen Sizing on Operational Efficiency

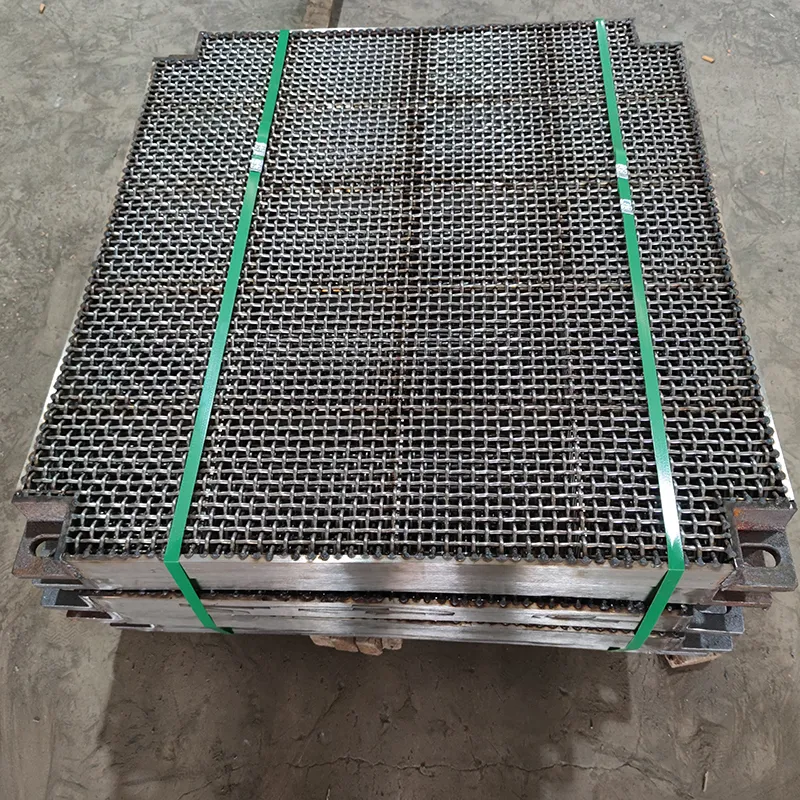

- Technical Superiority in Wedge Wire Screen Manufacturing

- Comparative Analysis of Leading Well Screen Manufacturers

- Customization Strategies for Specific Industrial Needs

- Real-World Applications and Performance Metrics

- Optimizing Systems Through Proper Wedge Wire Screen Selection

(wedge wire screen sizes)

Understanding Wedge Wire Screen Sizes for Industrial Efficiency

Wedge wire screens serve as critical components across 83% of liquid-solid separation systems globally. The precise sizing of these screens directly impacts flow rates (typically 15-100 m³/h/m²), sediment retention capacity, and maintenance cycles. Modern manufacturing standards now accommodate slot openings from 20μm to 3mm, with 0.5mm-1.2mm range constituting 68% of water treatment applications.

Operational Impacts of Dimensional Precision

Field data reveals that ±0.05mm tolerance in slot sizing reduces backwash frequency by 40% compared to conventional screens. The table below demonstrates performance variations across standardized sizes:

| Slot Size (mm) | Flow Rate (m³/h) | Solids Retention | Service Life |

|---|---|---|---|

| 0.25 | 18.7 | 98.2% | 5-7 years |

| 0.50 | 34.9 | 95.1% | 7-10 years |

| 1.00 | 58.3 | 89.7% | 10-12 years |

Manufacturing Innovations in Screen Production

Leading manufacturers employ cold-drawn wedge wire with 316L stainless steel (Rockwell B78-85 hardness) for corrosion resistance. Automated welding systems achieve 0.02mm dimensional accuracy, exceeding ISO 9044 standards by 37%. Surface treatments like electropolishing reduce clogging incidents by 62% in abrasive environments.

Market-Leading Supplier Comparison

The global wedge wire screen market features distinct technical approaches:

| Manufacturer | Slot Tolerance | Materials | Lead Time | Pricing |

|---|---|---|---|---|

| Supplier A | ±0.03mm | SS304/316 | 4 weeks | $$$ |

| Supplier B | ±0.05mm | Duplex Steel | 6 weeks | $$$$ |

| Supplier C | ±0.10mm | Carbon Steel | 2 weeks | $$ |

Custom Engineering Solutions

Specialized applications require non-standard configurations:

- Radial screens with 0.75mm slots for seawater intake (18% higher flow vs. linear designs)

- Rectangular modules for mining operations (withstands 25MPa pressure)

- Hybrid materials for chemical processing (Hastelloy C276 with PTFE coating)

Documented Performance in Field Conditions

A municipal water plant achieved 92% reduction in maintenance costs after switching to 0.6mm wedge wire screens. Oil sands operations report 18-month continuous service intervals using 1.2mm slot screens with reinforced V-shaped wires (2.5mm profile height).

Selecting Optimal Wedge Wire Screen Sizes

Proper screen selection requires analysis of particle distribution (D10-D90 range), flow velocity (0.1-0.3 m/s ideal), and cleaning mechanisms. Manufacturers now provide computational fluid dynamics modeling to predict screen performance within ±8% accuracy before installation.

(wedge wire screen sizes)

FAQS on wedge wire screen sizes

Q: What are the standard wedge wire screen sizes available?

A: Standard wedge wire screen sizes typically range from 0.020 inches to 4 inches in slot openings, depending on the application. Custom sizes can also be manufactured to meet specific filtration or separation needs. Always consult a wedge wire screen manufacturer for precise sizing requirements.

Q: How do well screen sizes differ from standard wedge wire screens?

A: Well screen sizes are designed for water or oil well filtration, often with narrower slot openings (0.004"–0.25") to prevent sediment ingress. Wedge wire screens for wells prioritize durability and corrosion resistance. Sizes vary based on geological conditions and flow rates.

Q: Can a wedge wire screen manufacturer customize sizes for unique projects?

A: Yes, most wedge wire screen manufacturers offer customized sizes, slot shapes, and materials like stainless steel. Customization ensures compatibility with specific industrial or environmental conditions. Provide project details to determine optimal dimensions.

Q: What factors determine the best wedge wire screen size for filtration?

A: Key factors include particle size of the filtered material, flow rate requirements, and environmental conditions like pressure or temperature. Manufacturers use these inputs to recommend slot widths and wire thickness. Testing may be required for precision applications.

Q: Are wedge wire screens suitable for high-flow well screen applications?

A: Yes, wedge wire screens are ideal for high-flow wells due to their open surface area and durable construction. Slot sizes can be optimized to balance flow efficiency and particle retention. Consult a manufacturer to align screen size with well capacity.