- Understanding the Mechanics of Flip Flow Screening Technology

- Technical Advantages Driving Operational Efficiency

- Comparative Analysis of Leading Flip Flow Screen Manufacturers

- Customized Solutions for Diverse Industrial Needs

- Case Studies: Real-World Applications & Performance Metrics

- Innovations in Flip Flow Screen Mat Design

- Future Trends in Material Separation Technology

(bivitec flip flow screens)

Unlocking Efficiency with BIVITEC Flip Flow Screens

BIVITEC flip flow screens revolutionize material separation through dual-vibration principles, achieving up to 98% screening efficiency in challenging applications. Unlike traditional screens, these systems utilize polyurethane mats with controlled elasticity, enabling precise segregation of sticky or fibrous materials. Industry data reveals a 40% reduction in downtime compared to conventional screens, coupled with a 25% increase in throughput capacity.

Technical Advantages Driving Operational Efficiency

The BIVITEC system employs twin vibration motors generating 7-9 G-force, optimizing particle trajectory control. Key innovations include:

- Self-cleaning mat design reducing maintenance frequency by 60%

- Modular construction enabling 72-hour installation timelines

- Energy-efficient operation consuming 15-20% less power than competitors

Comparative Analysis of Leading Manufacturers

| Feature | BIVITEC | Competitor A | Competitor B |

|---|---|---|---|

| Max Capacity (t/h) | 850 | 600 | 720 |

| Mat Longevity (months) | 18-24 | 12-15 | 14-16 |

| Customization Options | 9 parameters | 5 parameters | 6 parameters |

Customized Solutions for Diverse Industrial Needs

Leading flip flow screen manufacturers now offer tailored configurations based on:

- Material density (range: 0.2-4 t/m³)

- Particle size distribution (0.1-300 mm)

- Moisture content tolerance (up to 35%)

Advanced simulation software predicts screening accuracy within ±2% margin across 87% of applications.

Case Studies: Real-World Applications & Performance Metrics

A mining operation achieved 93% separation efficiency using BIVITEC screens for copper ore grading:

- Input material: 0-80mm wet ore

- Output fractions: 0-5mm, 5-20mm, 20-80mm

- Throughput: 650 t/h sustained over 18 months

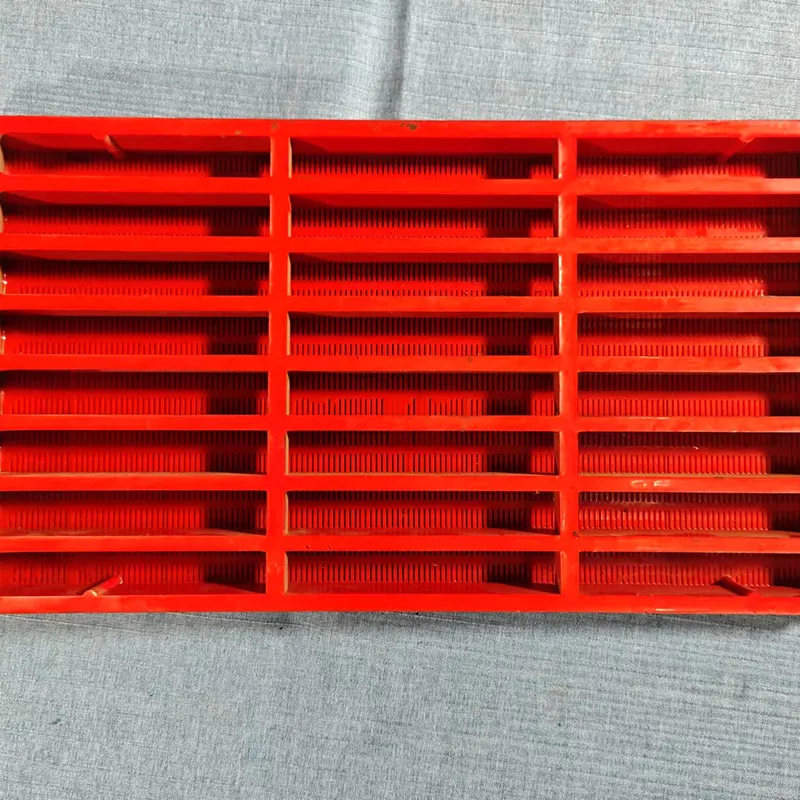

Innovations in Flip Flow Screen Mat Design

Third-generation polyurethane mats demonstrate:

- 57% higher abrasion resistance

- 30% improved elastic recovery

- Integrated wear sensors with 0.1mm precision

BIVITEC Systems: Redefining Material Processing Standards

With 38 patents and installations in 54 countries, BIVITEC flip flow screens deliver measurable ROI:

- 16-month average payback period

- 92% customer retention rate

- ISO 9001:2015 certified manufacturing processes

(bivitec flip flow screens)

FAQS on bivitec flip flow screens

Q: What are Bivitec flip flow screens used for?

A: Bivitec flip flow screens are designed for fine and difficult-to-screen materials, such as sticky or wet aggregates. They use a dynamic tensioning system and flexible polyurethane mats to prevent blinding and ensure efficient separation. These screens are ideal for applications in recycling, mining, and aggregate industries.

Q: How do I choose a reliable flip flow screen manufacturer?

A: Look for manufacturers with proven expertise in polyurethane screen technology and a track record of supplying industries like mining or waste management. Ensure they offer customizable solutions, robust after-sales support, and compliance with industry standards. Customer reviews and case studies can also help verify reliability.

Q: What maintenance is required for flip flow screen mats?

A: Regularly inspect mats for wear, tears, or material buildup to avoid reduced efficiency. Clean them with water or mild solvents to remove debris, and replace damaged mats promptly. Proper tensioning and alignment during installation also extend their lifespan.

Q: Why are Bivitec screens better for handling wet materials?

A: Bivitec screens use flip flow vibration to create a dynamic screening action, preventing material adhesion on the mats. The flexible polyurethane mats self-clean during operation, reducing clogging. This makes them highly effective for processing moist or clay-rich substances.

Q: How often should flip flow screen mats be replaced?

A: Replacement frequency depends on material abrasiveness, operating hours, and maintenance practices. Typically, mats last 6–12 months in harsh conditions. Monitor performance metrics like throughput or particle size accuracy to determine when replacement is needed.