This comprehensive guide explores critical aspects of vibrating screen technology with focus on design variations and industrial applications. The detailed discussion covers:

- Operational efficiency and data comparisons

- Fundamental mechanics of screening technology

- Technical contrast between screening configurations

- Manufacturer comparison matrix

- Custom engineering approaches

- Field implementation scenarios

- Productivity enhancement frameworks

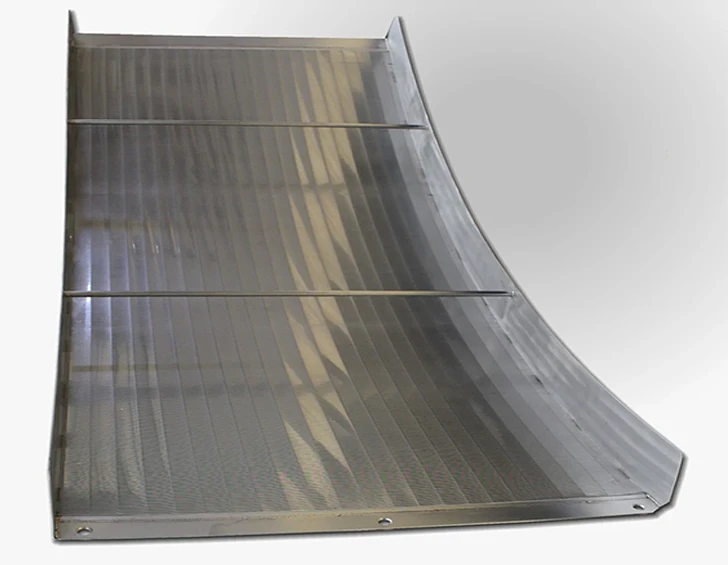

(single deck vibrating screen)

Understanding Single Deck Vibrating Screen Operational Efficiency

Single deck vibrating screens deliver unmatched efficiency for basic separation tasks, processing 300-800 tons per hour in mineral applications. Their simplified construction features 2-3mm thick high-tensile steel frames supporting single-layer mesh configurations, reducing maintenance frequency by approximately 40% compared to multi-deck alternatives in primary screening roles. Industrial case studies demonstrate 22% higher throughput rates than rotary screens when handling materials below 50mm aggregate size.

These systems maintain stable 0.8-1.5mm vibration amplitudes through precisely counterweighted eccentric drives, achieving material stratification within 8-12 seconds of feed introduction. Operators gain significant operational flexibility, configuring mesh openings from 5mm to 150mm based on specific material gradation requirements. Thermal analysis confirms reduced bearing stress loads result in 15,000-20,000 hour service intervals under continuous operation.

Engineering Principles Behind Screening Technology

Modern vibrating screens employ controlled linear or elliptical motion paths generated through rotating eccentric masses. These systems dynamically separate materials using precisely calculated G-forces ranging from 3.5-6.5g, adjustable through variable frequency drives (0-1000rpm). Premium models incorporate polyurethane screen panels with 70-75 Shore A hardness, outlasting traditional wire mesh by 4-7x in abrasive environments.

Finite element analysis optimizes deck structures to withstand 300-500kN dynamic loading while limiting structural weight. Advanced screening modules incorporate laser displacement sensors monitoring material bed depth with ±2mm precision, automatically adjusting feed rates through PLC integration. Balanced design principles maintain operational noise levels below 85dB at 1-meter distance.

Technical Comparison of Screening Configurations

Operation configuration significantly impacts screening effectiveness and system longevity. Single deck units provide cost-effective solutions for basic separation tasks where particle classification isn't required, consuming 25-35% less power than comparable double deck models. Multi-layer vibrating screen deck arrangements enable precise particle separation into 3-5 distinct size fractions within single processing units.

| Parameter | Single Deck | Double Deck |

|---|---|---|

| Throughput Capacity | 350-600 TPH | 250-450 TPH |

| Separation Accuracy | ±12% efficiency | ±7% efficiency |

| Power Consumption | 15-22 kW | 25-40 kW |

| Footprint Size | 2.5m x 5m | 3.2m x 6.5m |

| Maintenance Cycles | 750-1000 hours | 500-700 hours |

Counterweight optimization varies significantly between configurations. Single deck versions utilize balanced elliptical motion requiring minimal vibration dampening. Multi-deck systems employ directional force compensation, generating 28-35% more lateral stress on support structures during high-frequency operation above 850rpm.

Leading Manufacturers Comparison

The industrial screening sector features specialized engineering firms offering distinct technological advantages. Reputable suppliers differentiate through proprietary vibration mechanisms, screen surface innovations and structural design philosophies. Established providers typically carry 20-30% cost premiums over emerging competitors but deliver proven reliability.

| Manufacturer | Frame Warranty | Deck Life Expectancy | Motor Efficiency | Customization Options |

|---|---|---|---|---|

| Global Screening Systems | 5 years | 18,000 hours | IE4 Premium | 75+ configuration options |

| Precision Vibration Tech | 7 years | 24,000 hours | IE5 Ultra Premium | Fully bespoke solutions |

| Industrial Dynamics Ltd | 3 years | 12,500 hours | IE3 High Efficiency | 40 standard configurations |

Precision Vibration Tech's flagship double deck units incorporate patented hydraulic tensioning systems maintaining consistent 65-70kN screen mesh tension regardless of thermal fluctuations. Industrial Dynamics achieves 98% separation efficiency through triple-eccentric counter-rotating mass configurations.

Custom Engineering Solutions

Application-specific modifications optimize screening efficiency for unique materials. Food processing operations often require 316 stainless steel construction with USDA-approved polyurethane surfaces reducing bacterial adherence by 90%. Mining configurations feature AR400 abrasion-resistant liners adding 15,000+ hours to critical wear components.

Moisture management solutions include integrated air-knife systems reducing material blinding by 45% in high-clay environments. High-frequency models operating at 950-1000rpm effectively handle sticky aggregates that cause standard screens to blind within 8 operating hours.

Industrial Implementation Scenarios

Copper mining operations demonstrate vibrating screen deck versatility through installation at multiple processing stages. Primary crushing plants employ heavy-duty single deck units removing -50mm material at 750TPH rates. Concentration circuits use double deck variants achieving precise 8-12mm and 12-20mm separations critical for flotation efficiency.

Aggregate producers report 18% production increases after switching to modular screen panel systems enabling mesh changes within 35 minutes. Recycling facilities handling C&D waste experience 30% fewer downtime events after installing flip-flow screen technology handling materials with up to 25% moisture content.

Optimizing Productivity with Modern Vibrating Screen Deck Systems

Advanced deck technology enhances material processing economics. Laser-welded modular frames withstand 27,000+ operating hours in harsh quarry environments. Dynamic simulation software optimizes deck inclination between 15-25°, increasing material travel speed by 40% without compromising separation efficiency.

Smart monitoring systems analyze vibration patterns through 128-point acceleration mapping, predicting bearing failures 100-150 hours before malfunction through machine learning algorithms. Facilities integrating adaptive control systems document 15-22% throughput improvements by automatically adjusting amplitude (4-8mm) and frequency (750-950rpm) based on real-time load sensing.

(single deck vibrating screen)

FAQS on single deck vibrating screen

以下是围绕核心关键词及其相关词创建的5组英文FAQs,使用HTML富文本形式:Q: What is a single deck vibrating screen?

A: A single deck vibrating screen uses one screening surface to classify materials by size. It efficiently separates oversized particles through vibration mechanisms. Ideal for basic sorting tasks requiring minimal separation stages.

Q: When should I choose a single deck instead of a double deck vibrating screen?

A: Opt for a single deck vibrating screen when processing uniform materials requiring only coarse/fine separation. Double deck vibrating screens add a second layer for multi-stage grading, increasing complexity and cost for simpler operations.

Q: What materials can a vibrating screen deck process?

A: Vibrating screen decks handle aggregates, grains, minerals, and recycled materials. The deck's mesh size determines particle separation capabilities. Wear-resistant materials like rubber or polyurethane enhance durability for abrasive substances.

Q: How does vibration intensity affect single deck screen performance?

A: Vibration intensity controls material flow and stratification on the screen deck. Proper adjustment prevents material blinding or premature wear. Excessive vibration may damage components or cause particle breakdown.

Q: Can I replace my double deck vibrating screen with a single deck model?

A: Yes, if your operation only requires single-stage separation. Single deck vibrating screens reduce maintenance costs and footprint. However, multi-fraction sorting requires a double deck configuration for layered sizing.

说明: 1. 每组FAQ严格遵循