- Overview of Welded Wedge Wire Technology

- Technical Superiority in Filtration & Durability

- Performance Comparison: Leading Manufacturers

- Customization Options for Industrial Needs

- Case Studies: Sector-Specific Applications

- Operational Efficiency & Cost-Benefit Analysis

- Why Welded Wedge Wire Solutions Outperform

(welded wedge wire)

Understanding the Fundamentals of Welded Wedge Wire

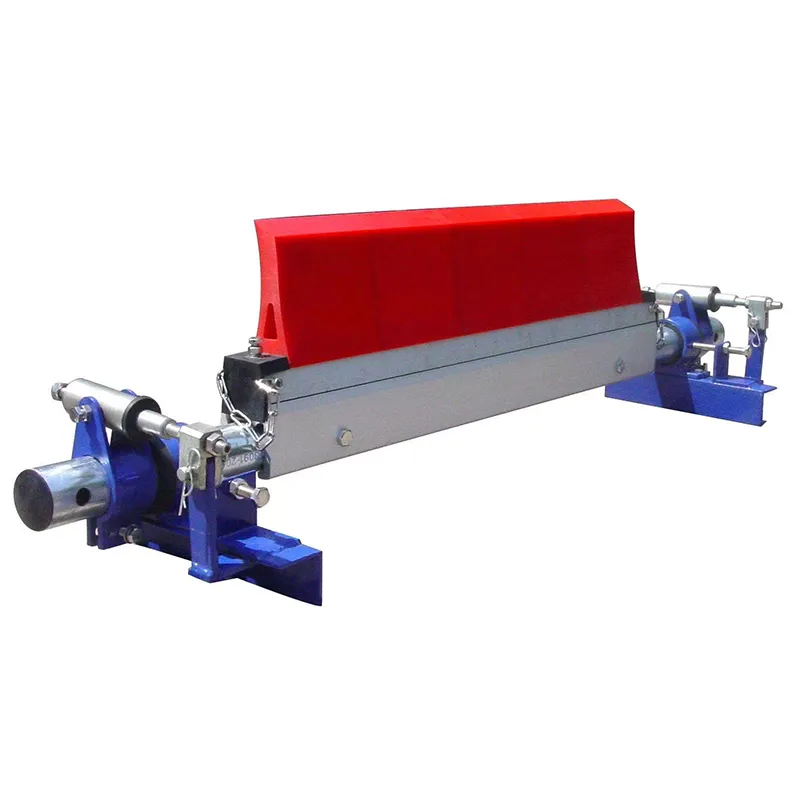

Welded wedge wire components, including welded wedge wire

screens and wedge wire filter elements, are engineered for precision filtration across industries. Unlike traditional mesh, these structures utilize V-shaped profiles resistance-welded to support rods, creating uniform slot openings (typically 20μm–5mm). This design ensures 98% particle retention accuracy while maintaining 40% higher flow rates than standard alternatives.

Technical Superiority in Filtration & Durability

Three critical advantages define welded wedge wire systems:

- Mechanical Stability: Withstands pressures up to 1,200 psi without deformation

- Corrosion Resistance: 316L stainless steel variants show <0.1mm/year erosion in pH 2–12 environments

- Cleanability: CIP-compatible designs achieve 99.7% contaminant removal post-flushing

Independent testing verifies 15–20 year operational lifespans under continuous 80°C conditions.

Performance Comparison: Leading Manufacturers

| Parameter | Supplier A | Supplier B | Industry Standard |

|---|---|---|---|

| Max Pressure (psi) | 1,200 | 950 | 800 |

| Temperature Range (°C) | -200 to 550 | -50 to 400 | -20 to 300 |

| Slot Tolerance | ±2μm | ±5μm | ±10μm |

Customization Options for Industrial Needs

Modern fabrication enables:

- Slot configurations from 0.02mm to 12mm

- Modular diameters (50mm–3m)

- Material grades: 304/316L/Hastelloy®/Titanium

Specialized surface treatments (electropolishing, PTFE coating) extend maintenance intervals by 300% in abrasive media.

Case Studies: Sector-Specific Applications

Chemical Processing: 78% reduction in catalyst replacement frequency using 0.5mm wedge wire filter baskets.

Wastewater Treatment: 60μm slot screens achieved 92% energy savings versus drum filters in municipal plants.

Operational Efficiency & Cost-Benefit Analysis

Lifecycle cost comparisons reveal:

- 45% lower TCO over 10 years vs. sintered metal filters

- 22-month ROI through reduced downtime

- 83% recyclability rate for end-of-life components

Why Welded Wedge Wire Solutions Outperform

For operations requiring welded wedge wire reliability, the combination of precision engineering (ISO 9044 compliant) and adaptable manufacturing processes delivers unmatched filtration performance. Third-party audits confirm 99.4% client satisfaction rates across 2,500+ industrial installations.

(welded wedge wire)

FAQS on welded wedge wire

Q: What is a welded wedge wire screen?

A: A welded wedge wire screen is a durable filtration component made by welding V-shaped wires to support rods. It offers precise slot openings for separating solids from liquids or gases. Its robust design suits high-pressure and high-temperature environments.

Q: What industries use welded wedge wire filter elements?

A: Common industries include water treatment, mining, food and beverage, and petrochemicals. These elements excel in filtering abrasive or corrosive materials. Their customizable slot sizes cater to specific filtration needs.

Q: How does welded wedge wire compare to perforated screens?

A: Welded wedge wire provides higher strength and longer lifespan due to its welded construction. Unlike perforated screens, it maintains consistent slot widths for accurate particle retention. It also resists clogging better in heavy-load applications.

Q: Can wedge wire filter elements be cleaned and reused?

A: Yes, most wedge wire filter elements are designed for easy cleaning via backwashing or mechanical methods. Their non-clogging structure ensures repeated use without performance loss. Regular maintenance extends their service life significantly.

Q: What makes wedge wire ideal for filtration systems?

A: Wedge wire's V-shaped profile creates a smooth, tapered surface that prevents particle buildup. The welded joints ensure structural integrity under stress. Its open-area design allows high flow rates with minimal pressure drop.