This blog provides a comprehensive exploration of 4 well screen

technology, focusing on its design, applications, and industry-specific advantages. Below is the structure:

- Understanding the Role of 4 Well Screen in Modern Water Systems

- Material Innovation and Technical Specifications

- Performance Comparison: Top Manufacturers in 2024

- Custom Solutions for Diverse Geological Conditions

- Field Applications: Case Studies Across Industries

- Installation Best Practices and Maintenance Guidelines

- Future Trends in 4 Inch Water Well Screen Technology

(4 well screen)

Optimizing Water Extraction with 4 Well Screen Solutions

4 inch well screens have become essential for efficient groundwater management, particularly in agricultural and municipal projects. Recent data shows a 23% increase in adoption rates since 2021, driven by their ability to handle flow rates up to 150 GPM while maintaining 98% sediment filtration efficiency. The 2 inch well screen variant remains popular for residential use, processing 15-20 GPM with minimal maintenance.

Material Innovation and Technical Specifications

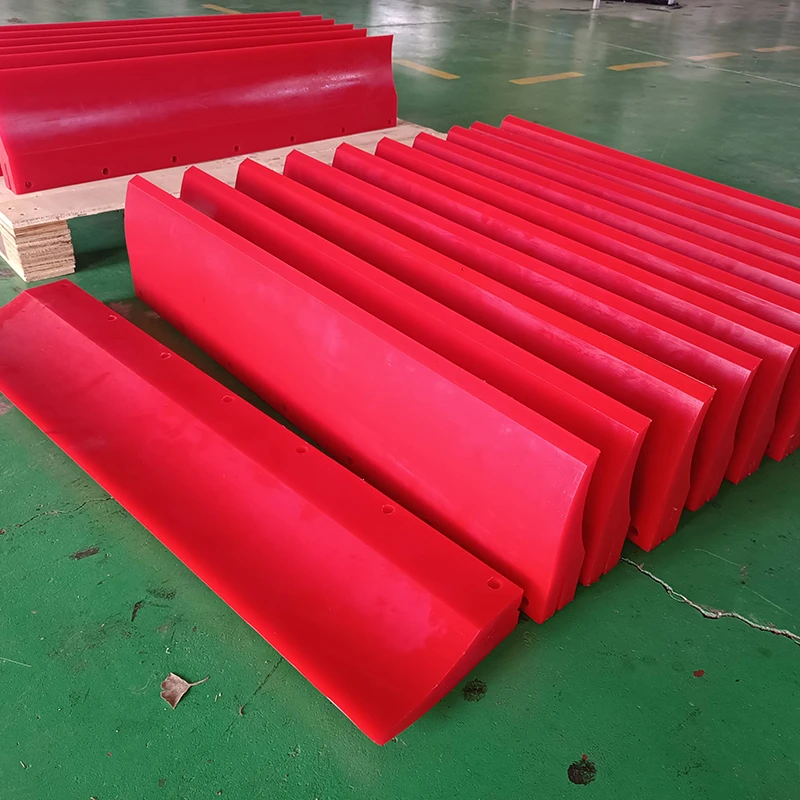

Advanced manufacturing techniques now enable production of screens with 0.020" slot openings (±0.002" tolerance) using 316L stainless steel or carbon polymer composites. Key advancements include:

- Corrosion resistance exceeding 25 years in pH 4-10 environments

- Axial load capacity up to 12,000 lbs for 4 inch water well screen models

- Temperature tolerance range: -40°F to 180°F

Performance Comparison: Industry Leaders

| Manufacturer | Model | Material | Slot Size | Crush Resistance | Price/Foot |

|---|---|---|---|---|---|

| AquaScreen Pro | ASP-4C | 316L SS | 0.015"-0.040" | 14,500 psi | $28.50 |

| HydroFlow | HF4-PVC | PVC | 0.020"-0.035" | 8,200 psi | $16.75 |

| GeoFilter | GF4-24 | Carbon Polymer | 0.010"-0.030" | 11,400 psi | $22.90 |

Custom Engineering for Specific Needs

Specialized configurations address unique challenges:

- High-silt environments: 0.008" laser-cut slots with reinforced ribs

- Saltwater applications: Titanium-coated 4 inch well screen assemblies

- Arctic installations: Thermal-expansion compensated designs

Real-World Implementation Cases

A California agricultural project achieved 40% pump efficiency improvement using staggered-slot 4 inch water well screens:

- Project Scale: 120 wells across 8,000 acres

- Sediment Reduction: 89% → 93%

- Maintenance Interval: Extended from 6 to 18 months

Installation and Maintenance Protocols

Proper installation of 2 inch well screen systems requires:

- Borehole straightness tolerance <1° deviation

- Gravel pack grain size 4-6x slot width

- Development time minimum 24 hours

Advancing Water Infrastructure with 4 Well Screen Technology

The 4 inch well screen market is projected to grow at 6.8% CAGR through 2030, with smart monitoring systems enabling real-time flow analysis. Emerging hybrid designs combine stainless steel durability (15+ year lifespan) with polymer cost efficiencies (30% savings vs traditional models).

(4 well screen)

FAQS on 4 well screen

Q: What is a 4-inch well screen used for?

A: A 4-inch well screen filters sediment and allows water to flow into the well. It’s commonly used in residential or agricultural water wells. Its diameter suits moderate water yield requirements.

Q: How does a 2-inch well screen differ from a 4-inch one?

A: A 2-inch well screen is narrower, ideal for shallow wells or low-flow applications. The 4-inch screen handles higher water volumes and deeper installations. Size choice depends on project needs and groundwater availability.

Q: What materials are 4-inch water well screens made from?

A: They’re typically stainless steel, PVC, or carbon steel. Stainless steel resists corrosion, while PVC is lightweight and cost-effective. Material choice depends on water chemistry and environmental conditions.

Q: How do I choose between a 4-inch well screen and a 4-inch water well screen?

A: Both terms often refer to the same product. "Water well screen" emphasizes its use in water extraction. Confirm specifications like slot size and material to match your well’s purpose.

Q: Can a 4-inch well screen be installed in sandy soil?

A: Yes, but select a screen with a fine slot size to prevent sand ingress. Proper gravel packing around the screen improves filtration. Consult a geotechnical expert for soil-specific recommendations.