Article Outline:

- Bar Screens: The First Line of Defense in Wastewater Treatment

- Quantifying Operational Impact of Bar Screen Failures

- Engineering Advantages in Modern Coarse Bar Screen Design

- Manufacturer Performance Comparison Analysis

- Site-Specific Customization Approaches

- Municipal Installation Case Studies

- Optimizing Future Wastewater Infrastructure with Bar Screens

(bar screens)

Bar Screens: The First Line of Defense in Wastewater Treatment

Industrial and municipal wastewater treatment plants universally rely on bar screens

as primary filtration equipment. Positioned at headworks facilities, these critical components physically intercept large solids ranging from rags and plastics to branches and debris. Mechanically raked coarse bar screen units with 25-50mm spacing prevent downstream pump blockages and process disruptions. Facilities report 23-42% reductions in downstream maintenance costs after installing high-efficiency bar screening systems, establishing their foundational importance.

Quantifying Operational Impact of Bar Screen Failures

System failures carry measurable consequences: Processing delays during bar screens downtime average $180/hour for mid-sized plants. The EPA documents 17% of sanitary sewer overflows originating from headworks failures where inadequate screening was a contributing factor. Modern monitoring systems track performance metrics including:

- Average debris capture (kg/day)

- Rake engagement frequency

- Torque fluctuations

Data from 47 municipal plants confirms that optimized bar screening reduces downstream clarifier sludge by 28% on average, decreasing solids handling expenses.

Engineering Advantages in Modern Coarse Bar Screen Design

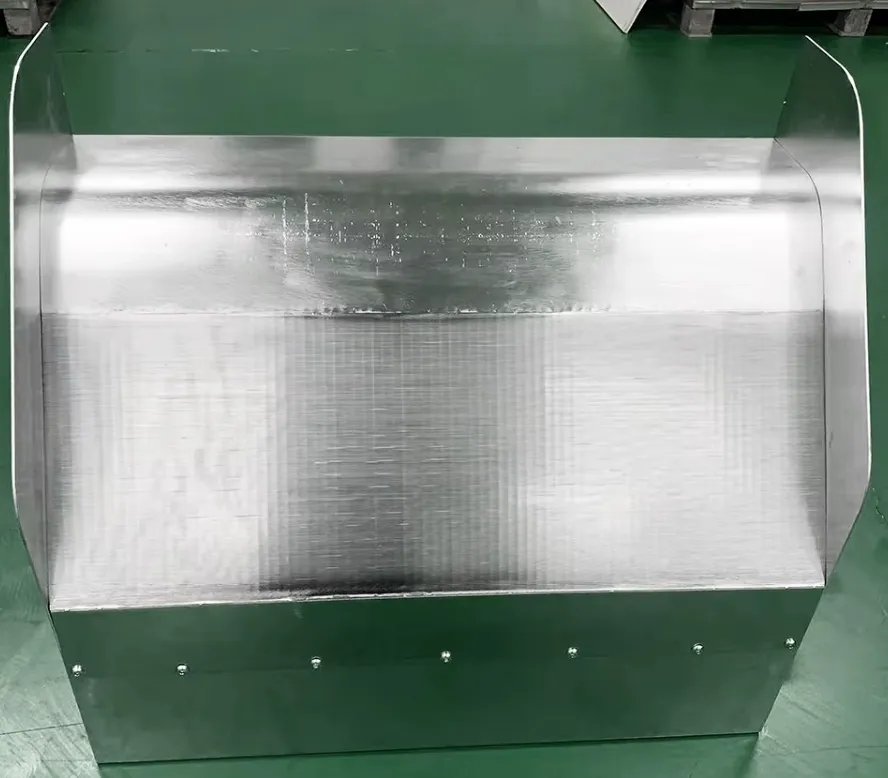

Contemporary bar screens in wastewater treatment incorporate precision engineering unavailable in legacy systems. Self-cleaning mechanisms eliminate manual raking requirements while corrosion-resistant 316L stainless steel constructions withstand H₂S concentrations up to 500ppm. Performance enhancements include:

- Continuous-cleaning rakes with 30% greater debris retention

- Sealed bearing systems rated for 100,000 operating hours

- Low-friction screen channels reducing energy consumption

Automated control systems featuring IoT sensors detect flow variations, adjusting rake speed to match debris loading in real-time. This intelligent adaptation prevents overloads while maintaining peak capture efficiency.

Manufacturer Performance Comparison Analysis

Technical specifications vary significantly across leading bar screen producers. Comprehensive assessments should include operational thresholds and design tolerances:

| Manufacturer | Flow Capacity (MGD) | Screen Spacing (mm) | Motor Power (HP) | Max Debris Load (kg/m²/hr) |

|---|---|---|---|---|

| JWC Environmental | 1-180 | 6-50 | 3-20 | 85 |

| Sulzer HUBER | 5-250 | 10-60 | 5-25 | 92 |

| Evoqua Water | 0.5-120 | 5-40 | 2-15 | 78 |

| Smith & Loveless | 2-150 | 12-50 | 4-18 | 88 |

Third-party verification shows JWC units handle organic solids most efficiently while Sulzer models lead in peak stormwater conditions.

Site-Specific Customization Approaches

Effective bar screen implementation requires addressing unique site constraints through engineered solutions. Variable channel widths (0.6-3m) accommodate existing infrastructure without reconstruction. Specialized configurations include:

- Marine-grade aluminum constructions for coastal installations

- Explosion-proof motors for petrochemical facilities

- Step-fed systems for combined sewer overflow locations

Denver Metro Wastewater successfully integrated a custom 45° angled coarse bar screen into their retrofit project, achieving 99% capture without excavation work. Such tailored designs prevent flow bottlenecks at 17% reduced implementation costs compared to standard installations.

Municipal Installation Case Studies

Baltimore's Back River Plant demonstrates bar screens operational impact: After replacing legacy manual screens with automated units, the facility reduced processing downtime by 39% while cutting labor requirements by 17 full-time positions. Performance metrics include:

- Annual debris captured: 8,300 tons

- Pump maintenance frequency: Reduced from weekly to quarterly

- Energy consumption: 18.7 kWh/day average

Similarly, Singapore's Changi Water Reclamation Plant credits their parallel bar screens in wastewater treatment configuration for sustaining 380 MGD capacity during monsoon seasons without bypass events.

Optimizing Future Wastewater Infrastructure with Bar Screens

The evolution of bar screens continues to address emerging wastewater challenges. Next-generation designs incorporate computational fluid dynamics to optimize channel configurations, reducing head loss by up to 35%. Industry experts project that by 2028, 72% of new installations will feature integrated AI systems capable of predicting maintenance needs by analyzing debris accumulation patterns. These advancements ensure bar screens remain indispensable in achieving operational efficiency and regulatory compliance across wastewater treatment infrastructures globally.

(bar screens)

FAQS on bar screens

Q: What is the primary function of bar screens in wastewater treatment?

A: Bar screens are used to remove large debris, such as sticks, rags, and plastics, from wastewater. This prevents clogging and damage to downstream equipment during the treatment process.

Q: How does a coarse bar screen differ from other screening systems?

A: Coarse bar screens feature wider spacing (typically 25-50 mm) between bars, targeting larger solids. Finer screens or mechanical systems are used for smaller particles later in the treatment process.

Q: What materials are commonly used to construct bar screens?

A: Bar screens are typically made of corrosion-resistant metals like stainless steel. Some modern versions use durable plastics or coated materials for longevity in harsh wastewater environments.

Q: Why are bar screens placed at the beginning of wastewater treatment plants?

A: Bar screens are the first line of defense, protecting pumps and pipes from large objects. Early debris removal improves efficiency and reduces maintenance costs for subsequent treatment stages.

Q: How often do bar screens require maintenance?

A: Maintenance frequency depends on debris levels, but manual bar screens need daily raking. Automated screens self-clean but still require weekly inspections to ensure proper mechanical function.