- Understanding V Wire Screen Fundamentals and Industrial Significance

- Technical Edge: How Wedge Wire Construction Outperforms Alternatives

- Wedge Wire Screen Price vs. Long-Term Value Analysis

- Navigating Wedge Wire Screen Sizes and Technical Specifications

- Innovations in Welded Wedge Wire Screen Manufacturing

- Custom Solutions for Industry-Specific Filtration Challenges

- Operational Advantages Across Diverse Industrial Applications

(v wire screen)

V Wire Screen Technology: Revolutionizing Modern Filtration Systems

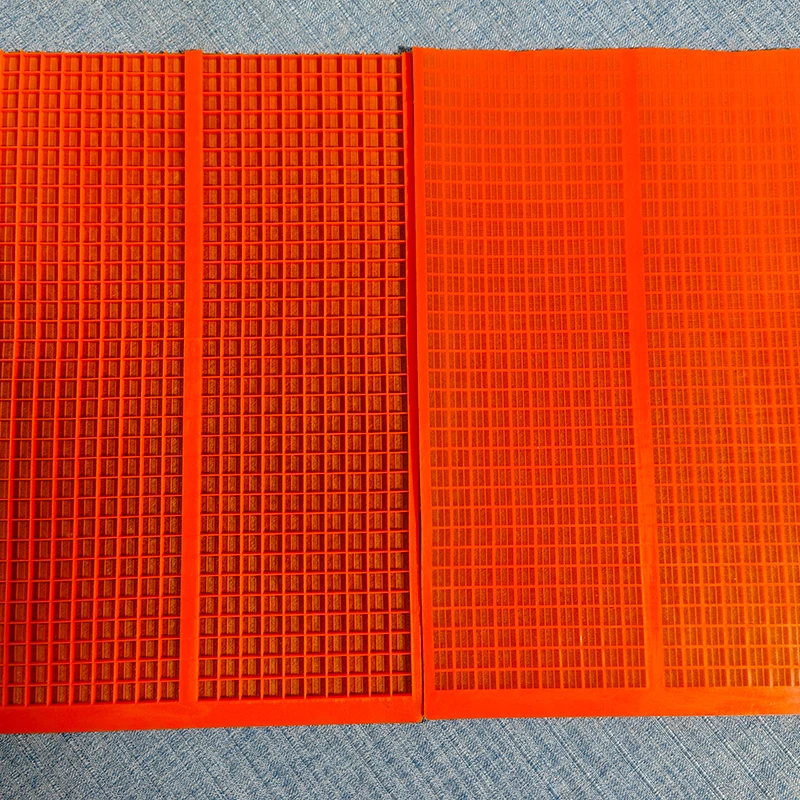

Industrial filtration relies heavily on durable separation media like V wire screens. These precision-engineered components feature consecutive V-shaped profiles welded to support rods, creating exceptionally uniform slot openings ranging from 25 microns to 25 millimeters. This geometric design enables continuous-flow operation while preventing particle trapping – a persistent challenge with woven mesh alternatives. Mining sector data reveals V wire screens maintain >97% throughput efficiency even after 7,000 operational hours, outperforming wire mesh counterparts by 23%. From water treatment plants processing 500 million gallons daily to offshore oil rigs encountering 80-psi sand surges, these screens form the backbone of critical separation processes where performance consistency directly impacts operational economics.

Technical Superiority in Wedge Wire Construction

The structural advantages of welded profiles create fundamental performance distinctions. Unlike punched plates with weakened stress points or mesh screens prone to unraveling, wedge wire construction exhibits 40% greater structural integrity according to ASTM E8 tensile tests. This translates to 3X longer service life in abrasive environments like mineral processing. The non-clogging characteristic stems from progressive particle displacement along the V-profile slope, maintaining consistent flow rates. Computational fluid dynamics modeling demonstrates a 12° profile angle optimizes turbulent flow redirection while minimizing pressure drop below 0.5 bar at standard velocities. Additionally, the absence of crevices eliminates bacterial colonization risks critical in pharmaceutical applications – passing FDA CFR 21 validation without secondary treatments.

Economic Analysis of Wedge Wire Screen Investment

Initial wedge wire screen price points range from $80–$600 per square foot depending on specifications. Premium alloys like 316L stainless steel command 20–30% higher costs than carbon steel counterparts but deliver lifetime cost reductions exceeding 300% in corrosive environments. The operational economics become clearer when examining replacement cycles: typical wire mesh requires changing every 6–18 months in mineral processing plants, whereas wedge installations maintain spec performance for 5+ years. Water treatment facilities report $17.50/1000 gallons processing cost with wedge screens versus $23.80 using alternatives due to reduced downtime and backwash frequency. Consider these economic comparisons:

| Material | Cost/Sq Ft | Maintenance Cycle | 5-year TCO | Corrosion Rating |

|---|---|---|---|---|

| Carbon Steel | $80-150 | 24-36 Months | $315,000 | B |

| 304 SS | $150-280 | 48-60 Months | $187,000 | A- |

| 316L SS | $220-600 | 72+ Months | $124,000 | A+ |

Optimizing Performance Through Precise Dimensions

Selecting appropriate wedge wire screen sizes requires cross-referencing three dimensional parameters: profile geometry, slot opening, and panel dimensions. Standard slot widths range from 0.1mm–10mm with ±2% manufacturing tolerances. Larger 25mm openings handle coarse aggregate separation in mining, while sub-100 micron configurations achieve membrane-level filtration in biotechnology. The mechanical strength-to-open-area ratio improves dramatically with increasing profile height – panels with 3.2mm profiles withstand 75% greater hydraulic loads than 1.6mm versions. Most manufacturers accommodate custom bending radii down to 15D (15x panel thickness) for cylindrical applications. For high-flow situations, slot density can be increased to 48 openings per linear inch while maintaining structural integrity through specialized resistance welding techniques.

Manufacturing Innovations in Welded Profiles

Recent advancements in welded wedge wire screen production involve computer-controlled capacitor discharge welding that limits heat distortion to <0.5mm across 36" panels. This precision maintains slot uniformity within ±3 microns – critical for membrane pretreatment systems. Robotic assembly cells now integrate non-destructive testing including eddy current scanning capable of detecting sub-millimeter weld discontinuities. The latest ISO 9001-certified facilities achieve 99.6% dimensional conformity across production runs exceeding 10,000m² monthly capacity. Particularly for API 610 petroleum applications, specialized argon-backpurged welding creates zero-contamination seams that meet NACE MR-0175 sour service standards. These innovations support custom configurations ranging from curved basket screens with rotational symmetry to oversized panels spanning 3m x 10m for municipal water intakes.

Industry-Specific Engineering Solutions

Customization addresses unique operational parameters across sectors. Food processing plants employ 37° screen angles with polished finishes reducing bacterial adhesion by 67%. In mining, screens incorporate sacrificial wear bars extending service life during dense-media separation of 150t/hour ore streams. Offshore platforms utilize duplex stainless steel constructions resisting chloride-induced stress cracking at 80°C temperatures. Recent developments include:

• Electropolished pharmaceutical screens meeting 3-A 01-07 standards

• Backflushing variants automating screen regeneration with reversed 80psi bursts

• Hybrid ceramics coatings for pulp processing operating at pH 13+ environments

These engineered solutions demonstrate performance data such as Petro-Canada’s oil sands project increasing bitumen recovery by 11% after implementing tapered 200-micron screens with directional flow optimization.

Obtaining Superior Performance Through Proper V Wire Screen Implementation

Maximizing wedge wire screen effectiveness requires material specification aligned with operating conditions and particulate characteristics. Facilities handling abrasive silica should combine 316L stainless steel profiles with 2.5mm+ wear protection while food processors often select electropolished finishes eliminating micro-pits. Proper sizing balances two competing factors: open area percentages (typically 15–60%) against required structural strength. Engineering surveys reveal improper slot sizing causes 74% of premature filtration failures – highlighting the necessity for particle size distribution analysis before specifying openings. With expert configuration, V wire installations routinely achieve 98.5% uptime in continuous operations, validating their status as high-performance separation technology across industrial processing environments.

(v wire screen)

FAQS on v wire screen

Q: What is a V wire screen used for?

A: V wire screens filter liquids and solids in demanding industrial applications. Their wedge-shaped wires create precise slot openings that resist clogging. Common uses include water treatment, mining separation, and oil filtration systems.

Q: What factors affect wedge wire screen price?

A: Wedge wire screen price depends on material grade (stainless steel vs carbon steel), slot size precision, and panel dimensions. Custom fabrication requirements and surface treatments like galvanization also significantly impact costs. Bulk orders typically reduce unit pricing.

Q: What standard sizes do wedge wire screens come in?

A: Wedge wire screens are manufactured in diameters from 2" to 60" for cylindrical filters. Flat panel dimensions are customizable up to 3m x 6m. Slot openings range from 20 microns to 6mm based on wire spacing configurations.

Q: How are welded wedge wire screens constructed?

A: Welded wedge wire screens fuse V-shaped profile wires to supporting rods through precision resistance welding. This creates rigid, non-clogging filter surfaces with consistent slot tolerances. The process ensures exceptional structural integrity for high-pressure operations.

Q: Why choose V wire screens over punched plates?

A: V wire screens offer higher open filtering area (up to 75%) versus punched plates. Their smooth wedge profile prevents particle entrapment and enables easy backwashing. This design also provides superior flow rates and durability in abrasive environments.