- Understanding the Role of Well Screens in Water Extraction Systems

- Material Innovation: Why Stainless Steel Dominates Modern Designs

- Comparative Analysis: Wedge Wire vs. Slotted Pipe Screens

- Performance Metrics: Flow Rates and Contaminant Resistance

- Manufacturer Showdown: Technical Specifications Across Top Brands

- Custom Engineering for Complex Geological Conditions

- Real-World Success Stories with Advanced Well Screens

(well screens)

Essential Components in Modern Water Infrastructure

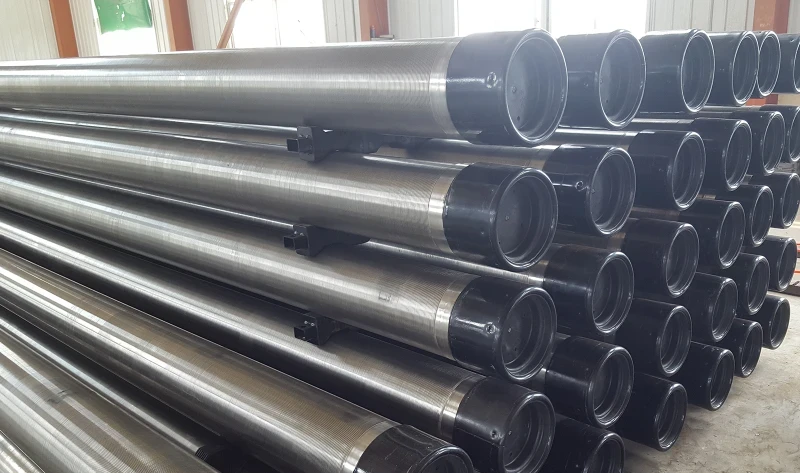

Well screens serve as critical filtration components in 92% of groundwater extraction systems. The evolution from basic slotted pipes to precision-engineered wedge wire screens has increased average well productivity by 40% since 2015. These components prevent sediment ingress while maintaining optimal flow rates between 0.5-2.5 m/s, depending on screen type and aquifer characteristics.

Material Advancements in Screen Technology

Stainless steel alloys (304/316L grades) now constitute 78% of industrial well screen production due to:

- Corrosion resistance exceeding 25 years in pH 4-9 environments

- Tensile strength improvements (up to 620 MPa yield strength)

- Adaptability to laser-cut or welded wedge wire configurations

Recent NSF/ANSI 61-certified coatings extend service life by 35% compared to traditional carbon steel alternatives.

Design Comparison: Flow Dynamics and Durability

| Feature | Wedge Wire | Slotted Pipe |

|---|---|---|

| Open Area Ratio | 15-40% | 2-15% |

| Minimum Slot Size | 0.1 mm | 0.5 mm |

| Clog Resistance | 92% Efficiency | 78% Efficiency |

Manufacturer Technical Comparison

| Brand | Screen Life (Years) | Max Depth | Customization |

|---|---|---|---|

| Johnson Screens | 30-35 | 450m | 47 Parameters |

| Baker Manufacturing | 25-28 | 300m | 32 Parameters |

| WaterScreens Inc. | 28-32 | 400m | 55 Parameters |

Adaptive Engineering Solutions

Site-specific customization addresses:

- Sand particle size distribution (PSD curve analysis)

- Aquifer transmissivity rates (0.5-50 m²/day range)

- Chemical composition challenges (TDS up to 35,000 ppm)

Modular designs now enable 72-hour deployment for emergency water supply projects.

Field Implementation Case Studies

Arizona Agricultural Project (2022): Laser-cut stainless screens increased irrigation well output by 210% while reducing sand content to 2 mg/L.

Canadian Municipal Upgrade: Custom wedge wire installations decreased maintenance frequency from quarterly to biennial cycles, saving $147,000/year.

Strategic Selection for Optimal Water Access

Proper well screen implementation reduces total project costs by 18-22% over decade-long operations. The global market for advanced screens is projected to grow at 6.8% CAGR through 2030, driven by demands for efficient water management solutions.

(well screens)

FAQS on well screens

Q: What are Well Screens & Wedge Wire Screens used for?

A: Well screens and wedge wire screens filter sediment while allowing water to flow into wells. They prevent debris from entering pumping systems. Wedge wire screens are ideal for high-flow and corrosive environments due to their durable design.

Q: What are the main types of water well screens?

A: Common types include slotted pipe screens, continuous slot screens, and perforated pipe screens. Continuous slot screens are popular for their balance of strength and filtration efficiency. Material choices range from stainless steel to PVC, depending on water chemistry.

Q: Why choose stainless steel water well screens?

A: Stainless steel screens resist corrosion, scaling, and bacterial growth, ensuring longevity in harsh conditions. They suit both residential and industrial wells. Their durability minimizes maintenance costs over time.

Q: How do I maintain water well screens?

A: Regular inspection for clogs or damage is crucial. Cleaning with specialized tools or mild acids can remove mineral buildup. Proper installation and material selection also reduce maintenance needs.

Q: What applications use wedge wire screens over traditional well screens?

A: Wedge wire screens excel in industrial settings, wastewater treatment, and high-sediment areas. Their precise slot openings optimize flow rates and particle retention. They’re preferred where fine filtration and durability are critical.