- Punch Plate Fundamentals and Material Science

- Performance Advantages in High-Impact Scenarios

- Comparative Analysis of Leading Manufacturers

- Custom Engineering Solutions for Specialized Applications

- Surface Pattern Optimization Techniques

- Documented Case Studies Across Industries

- Future Developments in PU Plate Technology

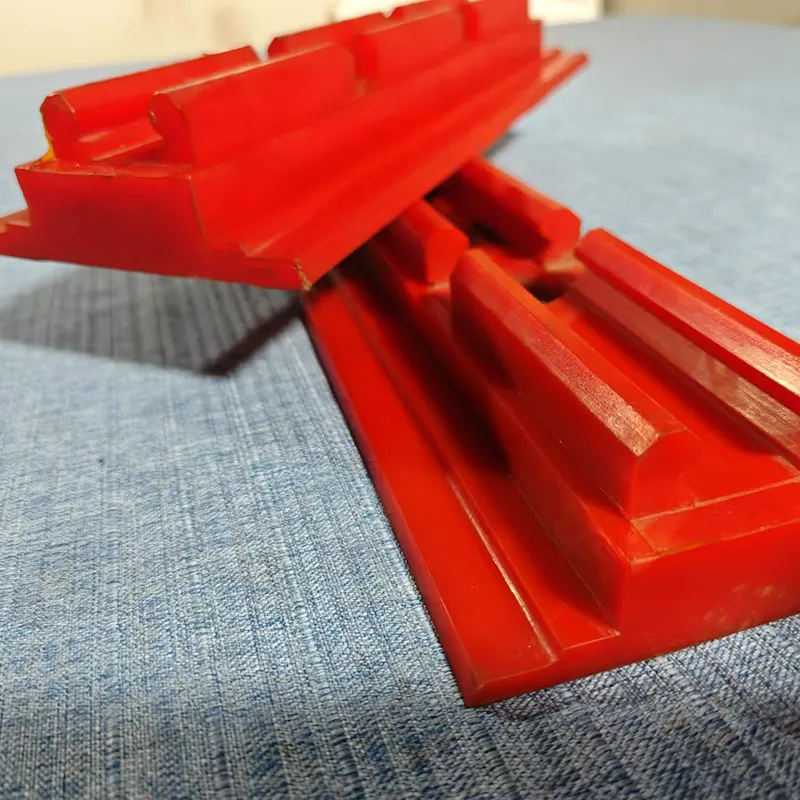

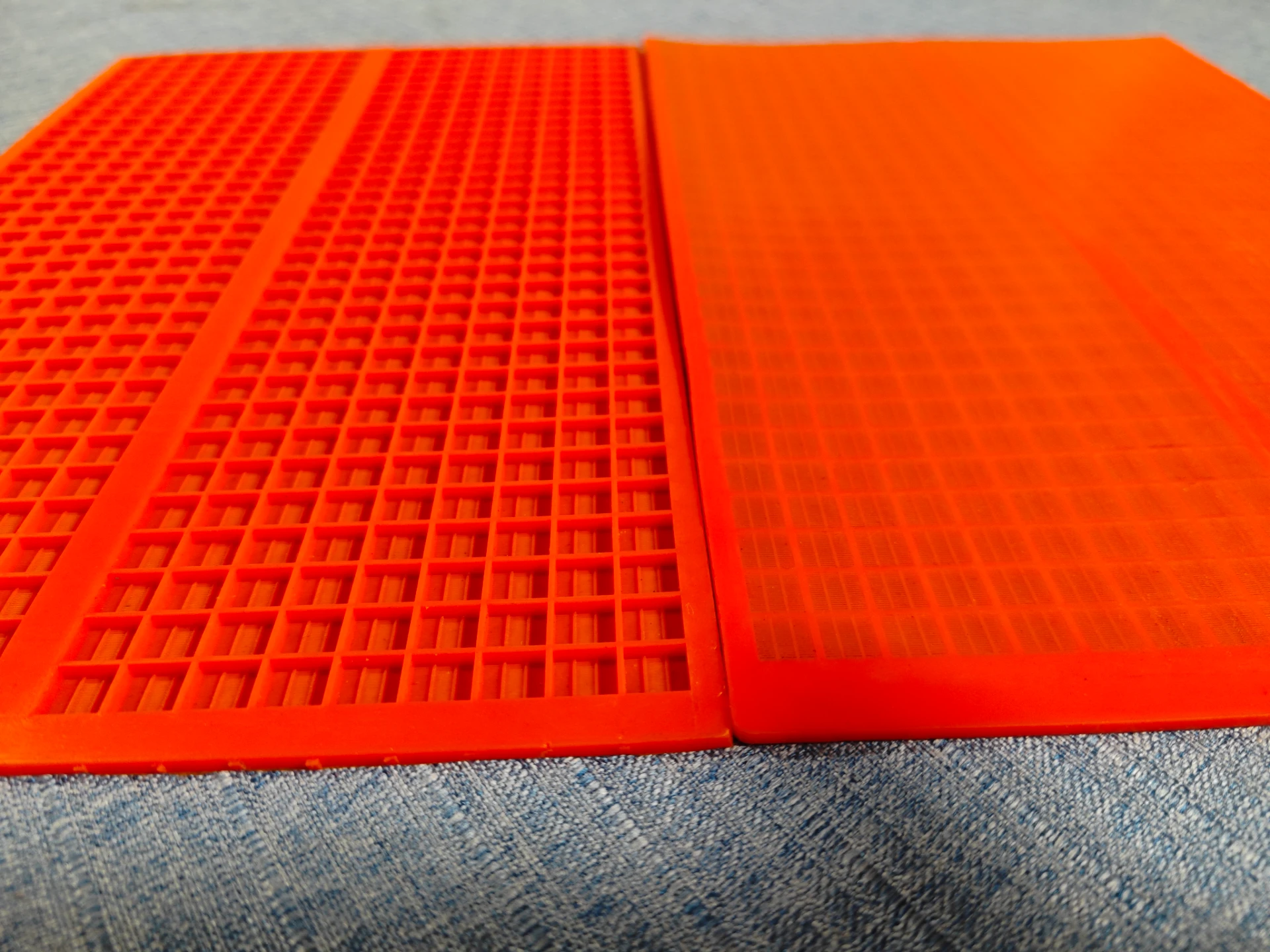

(punch plate)

Punch Plate Fundamentals and Material Composition

Modern punch plate

technology utilizes polyurethane (PU) compounds engineered for structural resilience in demanding environments. The molecular structure combines methylene diphenyl diisocyanate (MDI) with polyols to create cross-linked polymers exhibiting exceptional memory retention properties. Manufacturing involves precision-controlled pour molding techniques to achieve density ratings between 80-95 Shore A hardness with consistent thickness tolerances of ±0.5mm.

Primary technical specifications include:

- Tensile strength range: 3000-4500 psi

- Tear resistance: 400-600 pli

- Dynamic load bearing: Up to 3.5 metric tons/m²

- Operating temperature threshold: -40°C to +100°C

Performance Advantages in Industrial Applications

Industrial screening operations reveal significant performance differentials between polyurethane plates and conventional alternatives. Comparative testing under ASTM D4060 standards demonstrates PU plates provide 300% longer operational lifespans than equivalent rubber surfaces in mineral processing contexts. Noise attenuation measurements show 8-12 decibel reductions compared to steel screens.

The molecular elasticity enables permanent deformation resistance below 15% when subjected to 25mm aggregate impacts at terminal velocities. PU plates maintain dimensional stability at vibration frequencies reaching 1,800 RPM, far exceeding rubber alternatives which degrade beyond 1,200 RPM. The non-stick surface chemistry reduces material buildup by 60% versus metal surfaces.

Manufacturing Standards Comparison

| Parameter | Trelleborg | Rubbertek | Metso Outotec | Sandvik |

|---|---|---|---|---|

| Tensile Strength (psi) | 3800 | 3200 | 4500 | 4200 |

| Abrasion Loss (mm³) | 90 | 120 | 60 | 75 |

| Hardness Variation | ±3° | ±5° | ±2° | ±2.5° |

| Hole Tolerance (mm) | ±0.3 | ±0.45 | ±0.15 | ±0.25 |

| Lead Time (weeks) | 4-6 | 3-5 | 8-10 | 6-8 |

Custom Engineering Methodologies

Premium manufacturers offer advanced configuration parameters for application-specific requirements:

- Hole geometry customization (diamond, square, round)

- Open area adjustments from 15% to 65%

- Hybrid compounds with ceramic infusions

- Multi-density zoned constructions

Surface Optimization Techniques

Strategic perforation design requires computational fluid dynamics simulations to optimize material flow. For high-viscosity substances:

- Staggered hexagonal patterns increase screening velocity

- Progressive sizing reduces blinding incidents

- Elongated slots accelerate water drainage

- Ultrasonic cleaning ensures dimensional accuracy

- Non-stick coatings applied via plasma deposition

- Edge sealing prevents delamination

Documented Industrial Implementations

Coal Preparation Plant:

- Location: West Virginia, USA

- Installation: Banana screens with PU plates

- Outcome: Throughput increase from 250 to 360 TPH

- Durability: 14-month operation without replacement

Recycling Facility:

- Location: Rotterdam, Netherlands

- System: Conveyor impact beds with 45mm thick plates

- Result: Noise reduction from 105dB to 89dB

- Maintenance: Zero unscheduled downtime in 18 months

Innovations in Plate PU Technology

Research initiatives focus on developing conductive formulations that prevent static buildup during plastic screening. Material scientists are integrating embedded sensors that monitor wear patterns and predict failure thresholds with 95% accuracy. Sustainable manufacturing advancements include:

- Bio-based polyols replacing petroleum derivatives

- Closed-loop recycling systems reclaiming 98% of scrap material

Field tests confirm next-generation PU plates achieve 18% higher energy efficiency when installed on high-frequency vibratory systems. Anticipated developments include self-healing polymers and adaptive hole geometries that dynamically adjust to material characteristics.

(punch plate)

FAQS on punch plate

Q: What is a punch plate used for in industrial applications?

A: A punch plate is primarily used for screening and separating materials in industries like mining and construction. Its perforated design allows precise particle size sorting. It’s durable and ideal for heavy-duty processing.

Q: How does a PU plate differ from a standard punch plate?

A: A PU plate (polyurethane plate) offers enhanced flexibility and abrasion resistance compared to metal punch plates. It’s used in wet or corrosive environments where durability and noise reduction are critical. Both serve screening purposes but cater to different operational needs.

Q: Can a plate PU be customized for specific machinery?

A: Yes, plate PU screens can be tailored in thickness, hole size, and pattern to fit equipment like vibrating screens or trommels. Customization ensures optimal material flow and efficiency. Polyurethane’s moldability makes it ideal for unique industrial requirements.

Q: What factors affect the lifespan of a punch plate?

A: Material abrasiveness, operational frequency, and environmental conditions (e.g., moisture or chemicals) impact a punch plate’s longevity. Regular cleaning and proper tensioning during installation also play a role. Metal plates may corrode, while PU plates resist wear better.

Q: Why choose a PU plate over traditional metal punch plates?

A: PU plates reduce noise, absorb vibrations, and resist corrosion, making them suitable for food processing or recycling industries. They also minimize material clogging due to their non-stick surface. However, metal punch plates excel in high-temperature or extreme load scenarios.