- Introduction to wastewater screening fundamentals

- Performance data and efficiency metrics analysis

- Core engineering advantages over alternatives

- Comparative manufacturer specifications

- Custom configuration case studies

- Industry-specific implementation examples

- Operational best practices and maintenance

(parabolic screen)

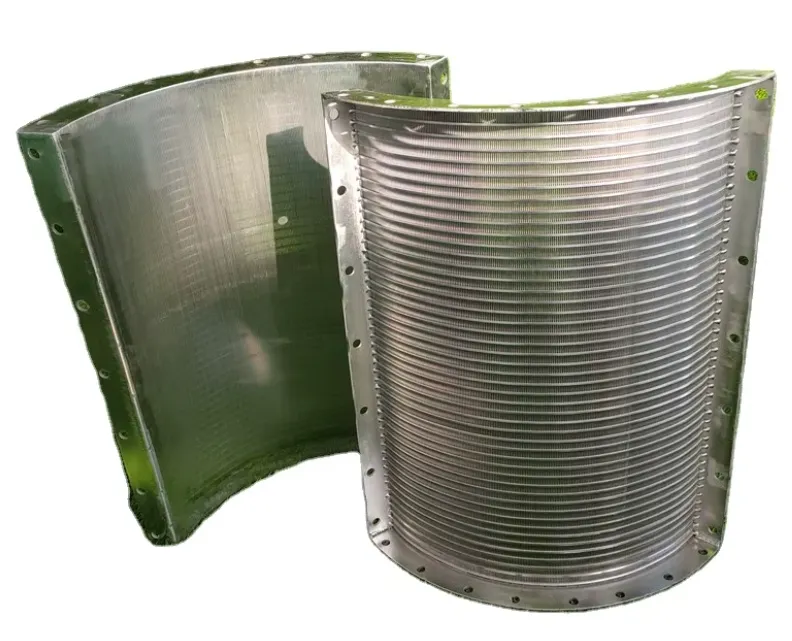

Revolutionizing Wastewater Management with Parabolic Screen Technology

Modern treatment facilities increasingly adopt parabolic screen

filters to overcome conventional screening limitations. These systems utilize a curved-bar design creating a self-cleaning mechanism that prevents debris accumulation - addressing the chronic clogging issues plaguing straight-bar alternatives. The geometry generates enhanced flow velocities across the screen surface, automatically ejecting captured solids toward collection troughs without mechanical intervention.

Municipal plants implementing parabolic screens report up to 78% maintenance reduction within the first year of operation. Critical data points from operational case studies reveal impressive performance benchmarks: average hydraulic throughput capacities of 650-2,200 l/s depending on channel width, sustained screening capture efficiency above 95% for particles exceeding 6mm, and power consumption averaging just 0.8-1.3 kW per installation. Industrial food processors using parabolic filters documented 61% fewer emergency shutdowns caused by inlet screen blockages while increasing influent processing capacity by up to 40% annually.

Fundamental Engineering Superiority

Unlike rotary drum screens or static step screens, parabolic units leverage fluid dynamics as their core operating principle. The patented crescent-shaped profile creates velocity gradients across the filter surface where maximum flow accelerates toward the screen apex. This generates hydraulic pressure differentials that automatically dislodge debris particles with velocities reaching 3.2 m/s - eliminating traditional raking mechanisms that represent frequent failure points.

The geometric efficiency translates directly to operational benefits:

- Non-clogging performance: Self-scouring design achieves uptime exceeding 98% even with heavy solids loading

- Construction integrity: Fabricated from marine-grade stainless steel (316L or duplex) with abrasion-resistant bars withstands 5-10 psi pressure differentials

- Space optimization: Compact designs deliver equivalent capacity in 45% less footprint versus conventional screens

Market Players: Performance Benchmarks

| Manufacturer | Slot Sizes (mm) | Max Capacity (MGD) | Hydraulic Efficiency | Unique Advantages |

|---|---|---|---|---|

| Hydro International | 3-25 | 180 | 92.4% | Modular cassette system |

| HUBER Technology | 1.5-12 | 225 | 94.1% | Integrated screenings compactor |

| Endura Systems | 2-30 | 160 | 89.7% | Submergence compensation |

Performance tests conducted at Ohio's Upper Scioto Water Reclamation Facility validated differentials: Hydro International's HyperRack™ demonstrated the lowest head loss at 0.8 inches across variable loading conditions. HUBER's RakeMax™ achieved superior fine screening capture rates at 1.5mm spacings while Endura's custom fabricated units supported highest pressure tolerance specifications for CSO applications. Selection criteria must prioritize site-specific requirements over generalized specifications.

Precision Configuration Methodologies

Effective wastewater parabolic screen deployment demands analytical parameter evaluation. Engineering teams must calculate channel hydraulics including peak flow velocity (target 0.7-1.2 m/s), screen submergence ratio (55-80%), and screening duty classification (standard, heavy, extreme). These variables dictate critical specifications:

- Bar profile geometry: Custom curvature ratios adapt to site-specific flow velocities

- Materials selection: Varying grades of stainless steel or non-metallic composites

- Slot density: Optimized clear spacing balancing capture efficiency vs head loss

Newark's sludge treatment plant retrofit achieved operational targets through parametric customization: increased bar thickness from standard 10mm to 15mm profiles extended service life 64% against abrasive grit. Custom 65-degree pitch adaptation reduced required channel length by 3.5 meters while achieving specified capture rates.

Industrial Success Profiles

Brewing Operation: Midwest craft brewery installed parabolic screen filters ahead of anaerobic digesters to process 320,000 GPD processing wastewater. Installation specifics included 6mm slots and duplex stainless construction to withstand corrosive organic acids. Resulted in 89% reduction in digesters grit accumulation and $28,000 annual savings via reduced maintenance.

Municipal WWTP: Coastal treatment plant utilized parabolic screens for stormwater inflow protection. Custom engineering implemented the TidalCompensator™ module automatically adjusting screen angle based on tidal influence, maintaining consistent capture efficiency despite varying hydraulic heads. Operational data demonstrated overflow prevention during storm surges affecting previous screening systems.

Enhancing Wastewater Infrastructure Through Parabolic Screen Innovation

Adopters must implement a robust maintenance protocol to maximize operational lifecycle and return on investment. Quarterly procedures should include bar clearance verifications ensuring spacing uniformity, torque confirmation for anchor systems, and velocity profile measurements. Predictive maintenance technologies increasingly incorporate embedded IoT sensors monitoring differential pressure readings across the screen, with data-driven algorithms triggering cleaning cycles only when needed, reducing mechanical wear.

Looking ahead, parabolic screen technology continues advancing through computational fluid dynamics modeling and next-generation composite materials. Current research focuses on asymmetric bar configurations that adapt screen angles to flow variations without mechanical actuators. Industry consensus confirms these innovations will consolidate parabolic systems as the standard for new-build treatment infrastructure globally, delivering unmatched resilience against increasingly challenging wastewater conditions.

(parabolic screen)

FAQS on parabolic screen

Q: What is a parabolic screen?

A: A parabolic screen is a mechanical filtration device with a curved surface designed to separate solids from liquids. It uses gravity and the screen’s shape to enhance efficiency in wastewater and industrial processes. Its design minimizes clogging and reduces maintenance needs.

Q: How does a parabolic screen filter work in wastewater treatment?

A: A parabolic screen filter uses its curved surface to guide wastewater flow, trapping solids while allowing liquids to pass through. The parabolic shape optimizes separation by leveraging gravity and fluid dynamics. This makes it ideal for removing debris in municipal or industrial wastewater systems.

Q: What are the advantages of a parabolic screen over traditional screens?

A: Parabolic screens offer higher efficiency in solid-liquid separation due to their curved design, which reduces blockages. They require less maintenance and energy compared to flat or vibrating screens. Additionally, their durability ensures longer operational lifespans in harsh environments.

Q: Can parabolic screens handle high-flow wastewater applications?

A: Yes, parabolic screens are designed to manage high-flow wastewater streams efficiently. Their self-cleaning mechanism and robust structure prevent performance drops under heavy loads. This makes them suitable for large-scale treatment plants and industrial facilities.

Q: How often does a parabolic screen filter need maintenance?

A: Maintenance frequency depends on the application and solids load, but parabolic screens typically require minimal upkeep. The curved design reduces debris buildup, and routine inspections every 3–6 months are usually sufficient. Automated cleaning systems can further reduce manual intervention.