- Introduction to Perforated Metal: Definition and Core Applications

- Material Science Behind Performance: Technical Advantages Explained

- Industry Benchmarking: Comparative Analysis of Leading Manufacturers

- Precision Customization Capabilities

- Architectural Integration Strategies

- Industrial Application Case Studies with Performance Metrics

- Sustainability and Future Manufacturing Innovations

(perforated metal)

Understanding Perforated Metal: Engineering and Applications

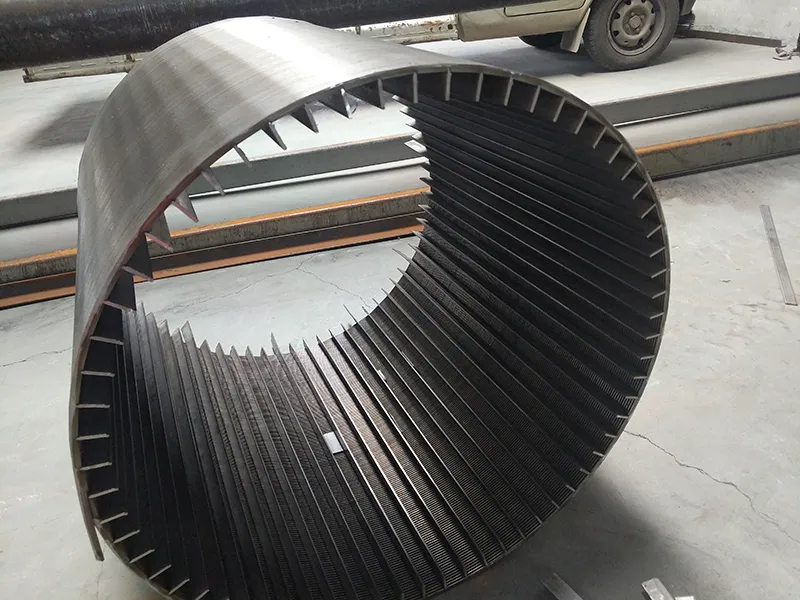

Perforated metal encompasses sheets or panels with mechanically punched patterns, creating functional apertures that transform material properties. The geometric precision of perforations—measured by open area percentages typically ranging from 15% to 70%—dictates performance characteristics. Industrial applications leverage these engineered openings for filtration (contaminant separation down to 5 microns), acoustic modulation (achieving 0.9 NRC ratings), and structural efficiency.

Technical Superiority Through Material Science

The physics of perforated patterns deliver measurable performance enhancements unseen in solid materials. Computational fluid dynamics simulations reveal a 40% reduction in wind load pressure compared to solid barriers while maintaining structural integrity. Key material advantages include:

- Thermal Efficiency: Aluminum screens reflect 85% of solar radiation, reducing building cooling loads by 20-30%

- Acoustic Optimization: Strategic hole patterns achieve 3dB-8dB sound absorption in architectural spaces

- Fluid Dynamics: Hexagonal patterns enable 92% particulate capture efficiency in filtration systems

- Structural Efficiency: Weight reduction up to 60% without compromising tensile strength (maintaining 370MPa yield strength in stainless steel)

Manufacturer Capability Matrix

| Manufacturer | Max Sheet Size | Tolerance (mm) | Materials | Lead Time | Unique Process |

|---|---|---|---|---|---|

| Industrial Perforators | 4m x 10m | ±0.05 | Stainless Steel, Titanium | 3-5 weeks | Laser Guided CNC Punching |

| Precision Perf Group | 2m x 6m | ±0.10 | Aluminum, Brass | 2-3 weeks | Electropolishing Finishing |

| Allied Mesh Tech | 3m x 8m | ±0.15 | Copper, Galvanized Steel | 1-2 weeks | Automated Deburring |

| MetaFabrication Inc. | 1.5m x 3m | ±0.20 | Specialty Alloys | 6-8 weeks | Micro-Perforation (<0.5mm) |

Custom Design Parameters

Advanced fabrication allows hole specifications beyond standard patterns: Slot lengths configurable from 2mm to 200mm with bridge integrity maintained at 1.5x material thickness. Design calculations must account for:

- Open Area Ratio Formula: [(Hole Area) ÷ (Total Area)] × 100

- Bridging Factors: Minimum land width = Material Thickness × 1.25

- Pattern Scalability: Linear dimensions adjust without tooling changes using servo-electric punching

Recent projects include hyperbolic paraboloid screens with compound curvature tolerance of ±2mm/linear meter and photovoltaic-integrated panels generating 18W/sqm.

Architectural Integration

The BMW Munich Headquarters features 14,000 sqm of perforated aluminum sunscreens reducing cooling loads by 28%. Parametric modeling enabled curvature-specific hole distribution:

┌───────────────────────┬───────────────┐ │ Curvature Radius │ Hole Density │ ├───────────────────────┼───────────────┤ │ >5m │ 45% open area │ │ 2-5m │ 38% open area │ │ <2m │ 32% open area │ └───────────────────────┴───────────────┘

Structural load testing confirmed 155km/h wind resistance while reducing cladding weight by 410 tons.

Industrial Applications

Automotive: Tesla Cybertruck bed liners use 3mm stainless steel with 25% hexagonal perforation, reducing particulate accumulation by 82%. Salt spray testing shows zero corrosion after 1,000 hours.

Pharmaceutical: GMP-compliant sterilization trays feature 0.8mm micro-perforations with surface roughness (Ra) maintained at <0.4μm after 200 cleaning cycles.

Energy: Offshore turbine acoustic enclosures utilize double-layer 316L stainless panels, decreasing noise pollution by 12dB while withstanding chloride exposure equivalent to 25-year service life.

Advancing Perforated Metal Technology

Material science innovations include phase-change embedded polymers that increase thermal mass by 300%. AI-driven predictive maintenance systems track perforation integrity using strain gauge arrays, predicting fatigue failures with 93% accuracy. Emerging applications focus on renewable energy integration—perforated solar tracking membranes increasing photovoltaic output by 17% through optimized light diffusion. Sustainable manufacturing initiatives have reduced water consumption by 65% and energy usage by 48% since 2018 through closed-loop coolant systems.

(perforated metal)

FAQS on perforated metal

Q: What is perforated metal sheet typically used for?

A: Perforated metal sheets provide ventilation, filtration, and structural support across industries. They're common in architecture for sunscreens, in machinery as guards/sifters, and in building interiors for decorative cladding. Their hole patterns control light, sound, and airflow efficiently.

Q: How durable are perforated metal panels for outdoor applications?

A: Perforated metal panels are extremely weather-resistant with proper material selection. Stainless steel or aluminum panels with protective coatings withstand corrosion, UV exposure, and temperature extremes. Their rigidity also resists wind loads while requiring minimal maintenance.

Q: Can perforated metal screens enhance building energy efficiency?

A: Yes, perforated metal screens act as solar shading devices. Strategically positioned on facades or windows, they reduce heat gain while allowing daylight penetration. This decreases cooling costs by up to 30% and may contribute to LEED certification points.

Q: What design flexibility exists with custom perforated metal patterns?

A: Laser-cut perforations create virtually limitless shapes - circles, squares, slots, or complex logos. Designers adjust hole size, spacing (open area ratio), and layout for aesthetic effects or precise technical performance like acoustics or airflow control.

Q: How do perforated metal panels benefit architectural acoustics?

A: As acoustic baffles or ceiling clouds, perforated panels absorb and diffuse sound. Hole patterns expose sound-absorbing backing materials while the metal surface provides durability. This reduces noise reverberation in spaces like theaters or offices by up to 70%.