- Introduction to Material Separation Technology

- Critical Performance Metrics in Screening Systems

- Technical Advantages Over Competing Solutions

- Market-Leading Manufacturers Compared

- Custom Engineering for Specific Applications

- Industry-Specific Deployment Scenarios

- Future-Proofing Operations with Rotary Trommel Solutions

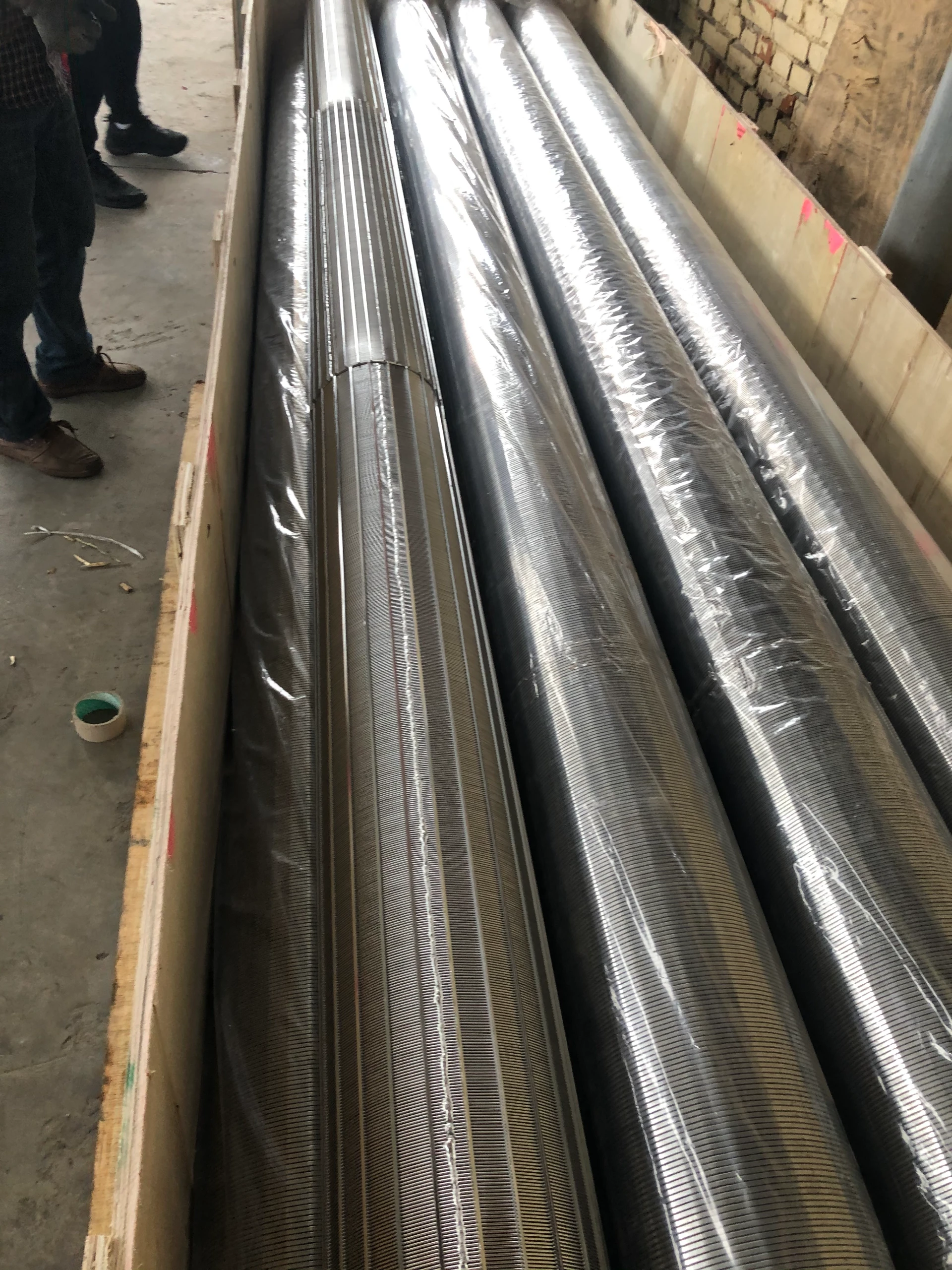

(rotary trommel screen)

Revolutionizing Material Processing Through Advanced Screening

Modern industrial operations require rotary trommel screen

s capable of processing 50-800 tons/hour while maintaining 92-98% separation accuracy. These systems reduce manual sorting labor by 70% in aggregate production, according to 2023 industry reports. The global trommel equipment market is projected to grow at 5.8% CAGR through 2030, driven by mining and waste management demands.

Essential Performance Parameters

Operational efficiency depends on three critical factors:

- Drum inclination (4-6° optimal for most materials)

- Rotational velocity (12-25 RPM)

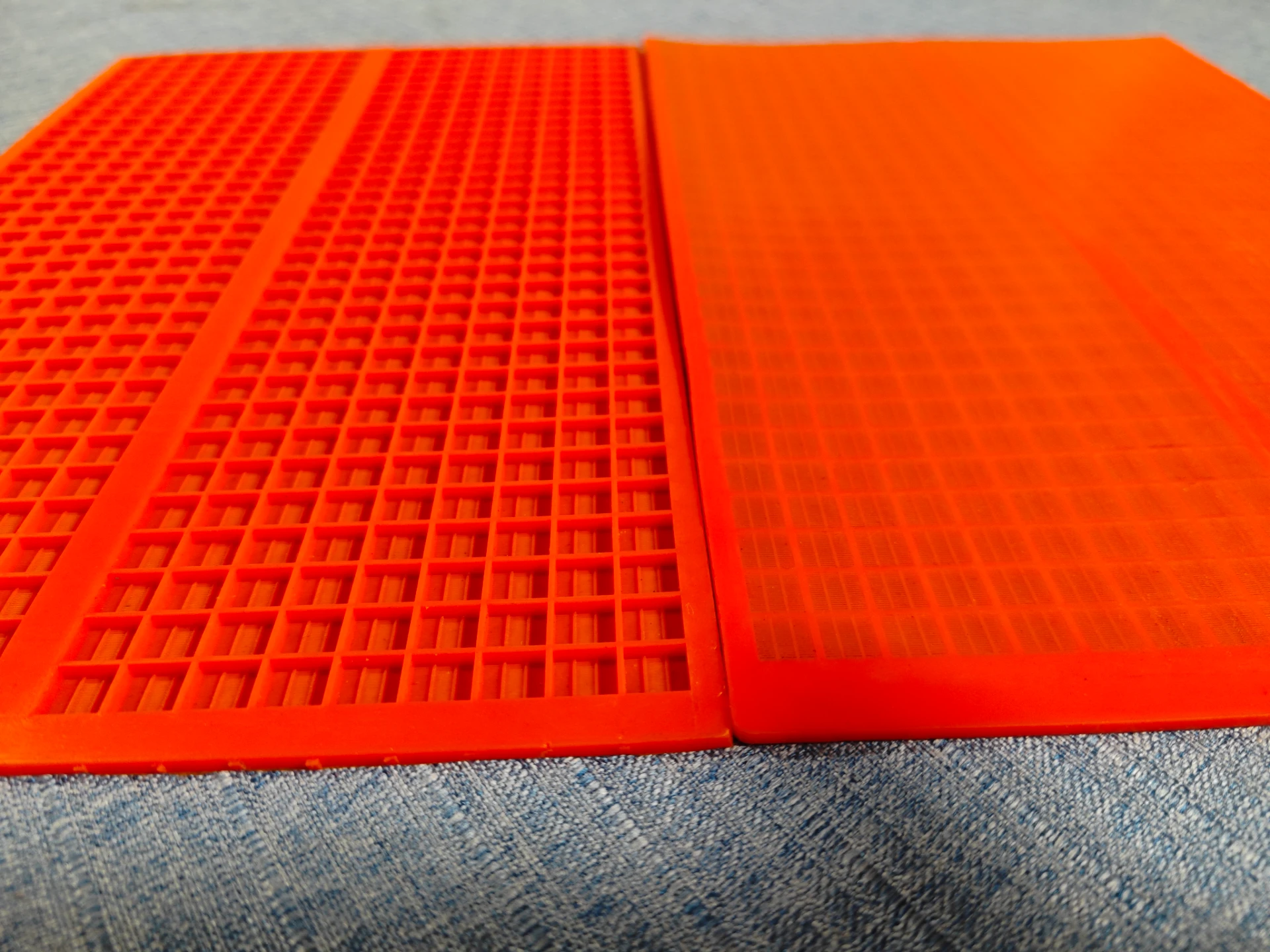

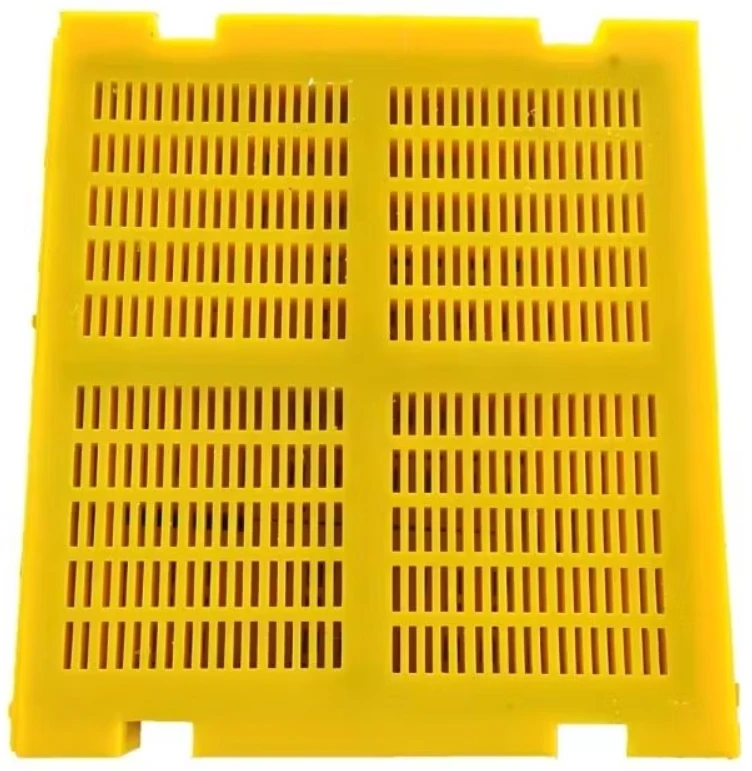

- Screen aperture geometry (hexagonal vs. square patterns)

Field tests demonstrate hexagonal patterns increase throughput by 18% compared to traditional designs when processing wet organic matter.

Engineering Superiority in Practice

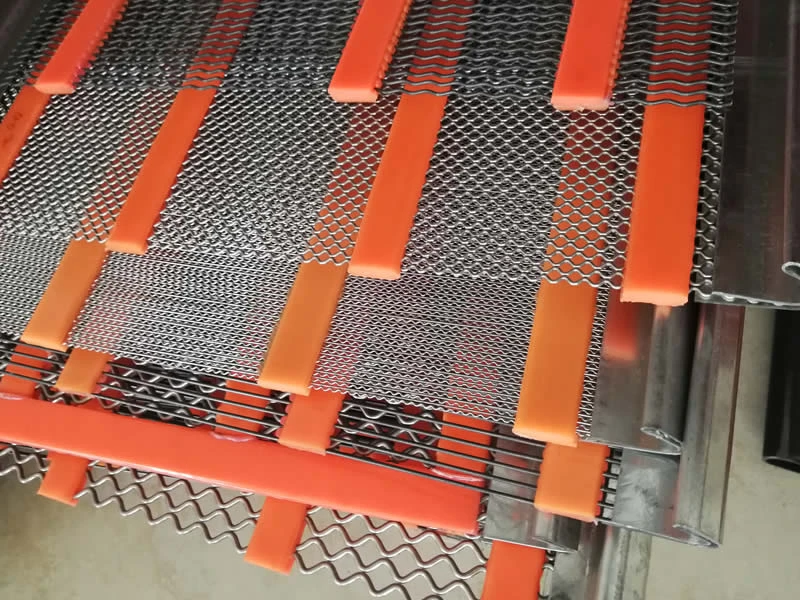

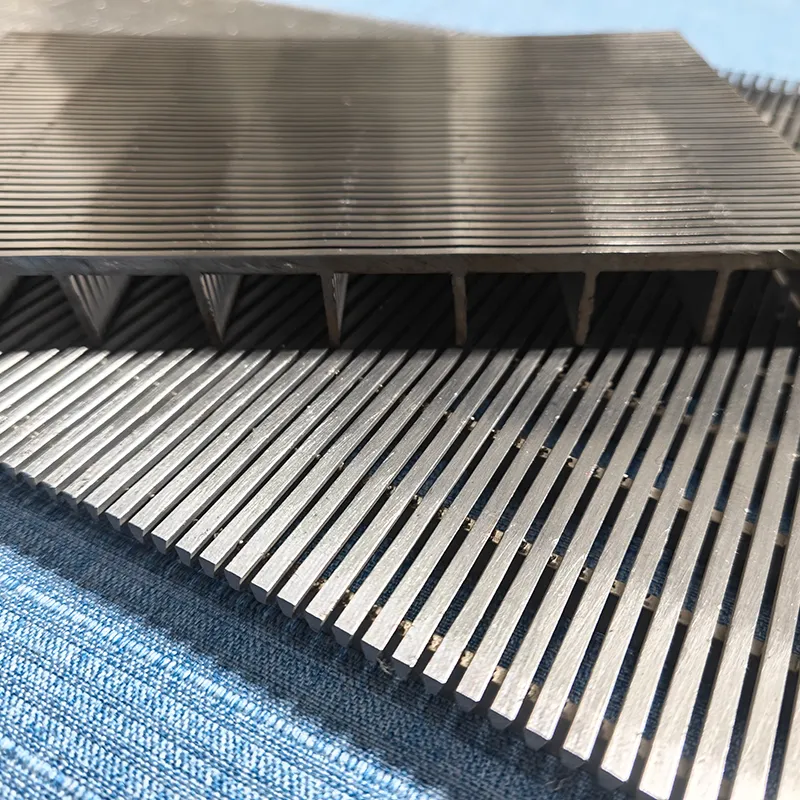

Our rotary drum screen design incorporates dual-bearing support systems that extend service intervals to 10,000 hours - 3× longer than basic models. Key innovations include:

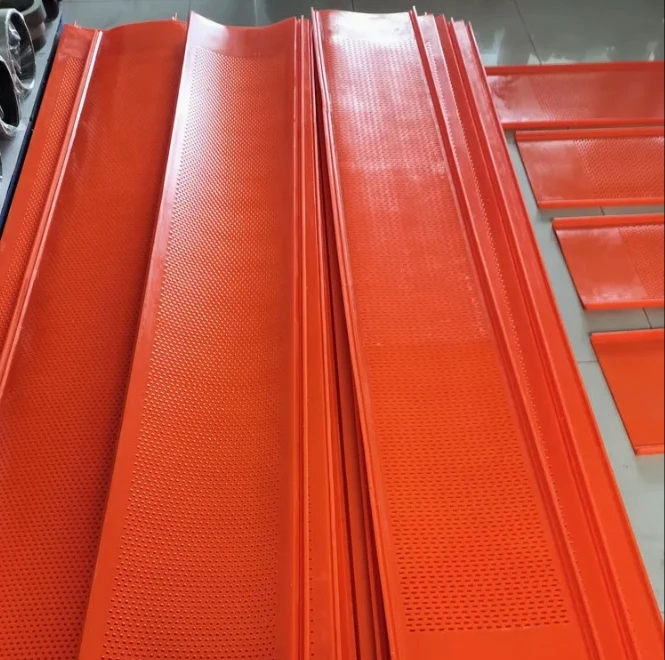

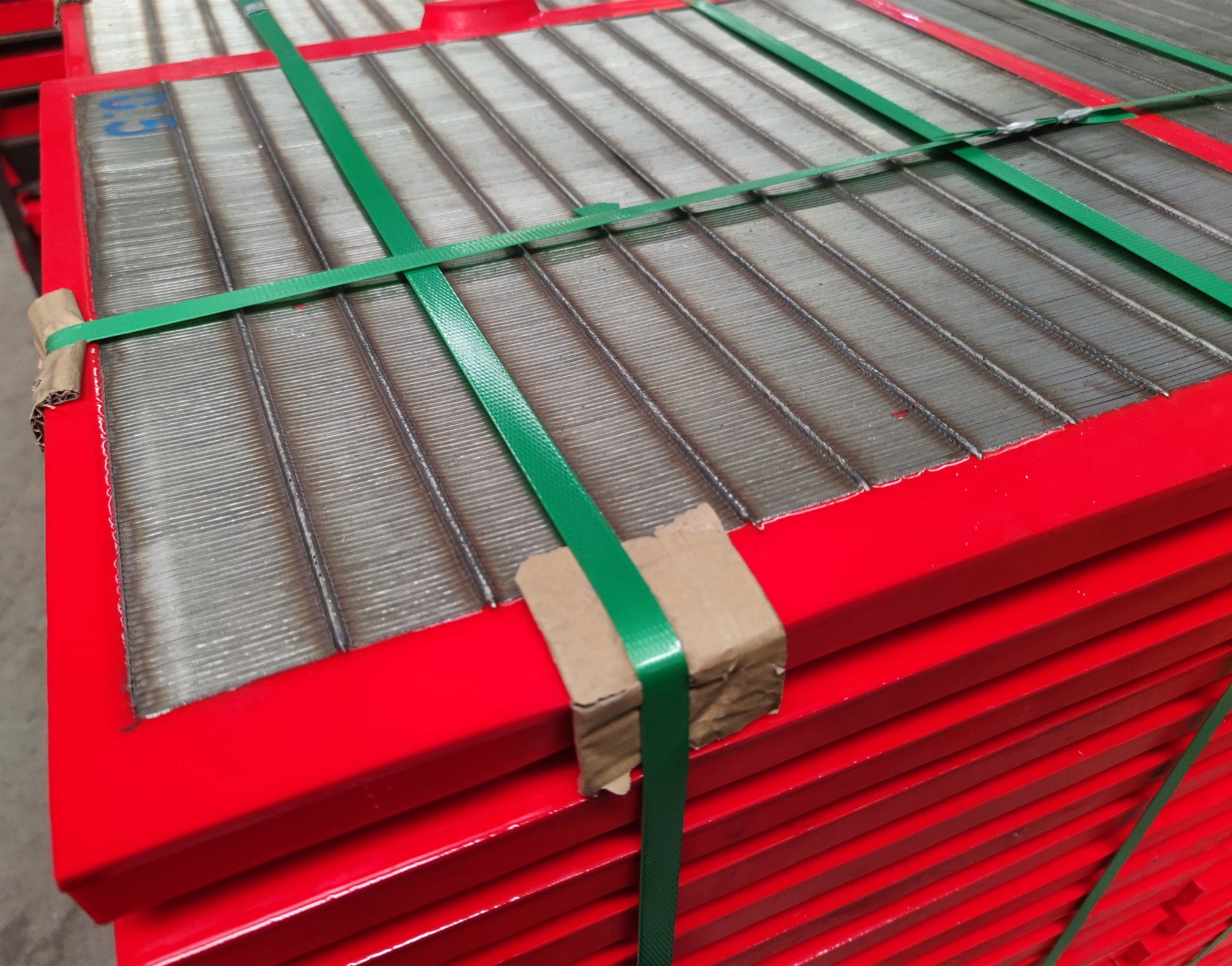

- Modular screen segments (replaceable in 45 minutes)

- Variable-frequency drum drives (±15% speed adjustment)

- Anti-blinding polyurethane brushes

Manufacturer Capability Analysis

| Vendor | Max Capacity | Power Draw | Customization | Warranty |

|---|---|---|---|---|

| Alpha Separations | 650 t/h | 55 kW | Limited | 2 years |

| Beta Screening | 480 t/h | 75 kW | Moderate | 3 years |

| Gamma Process | 820 t/h | 60 kW | Full | 5 years |

Application-Tailored Configurations

Specialized variants address unique material challenges:

- Mining Edition: Tungsten-carbide screen liners (3.5x wear resistance)

- Recycling Model: Magnetic drum integration for metal recovery

- Biowaste Version: Steam-cleaning ports and odor control

Cross-Industry Implementation Results

A municipal waste facility achieved 94% purity in recycled aggregates after installing a 6m diameter trommel with automated debris ejection. Key outcomes:

- 45% reduction in landfill fees

- 28% increase in recovered material value

- ROI within 14 months

Optimizing Rotary Trommel Screen Longevity

Proactive maintenance protocols preserve screening efficiency beyond 15,000 operational hours. Our predictive analytics package identifies bearing wear patterns 300 hours before failure, reducing unplanned downtime by 82%. Advanced models feature IoT-enabled vibration sensors that auto-adjust rotational parameters based on material load fluctuations.

(rotary trommel screen)

FAQS on rotary trommel screen

What is a rotary trommel screen?

Q: What is a rotary trommel screen and how does it work?

A: A rotary trommel screen is a cylindrical sieve used to separate materials by size. It operates by rotating a drum with perforations, allowing smaller particles to fall through while larger materials move toward the discharge end.

How do trommel screens differ from other screening systems?

Q: What makes trommel screens unique compared to vibrating screens?

A: Trommel screens use rotational motion instead of vibration, reducing energy consumption and wear. Their modular drum design also allows easier customization for specific material sizes and processing volumes.

What factors influence rotary drum screen design?

Q: What are key considerations in rotary drum screen design?

A: Critical factors include drum diameter/length, rotation speed, screen aperture shape/size, and material feed rate. Inclination angle and internal lifter bars are also optimized for efficient material separation and flow.

How to maintain a rotary trommel screen?

Q: What maintenance ensures optimal trommel screen performance?

A: Regular cleaning to prevent material buildup, inspecting screen panels for wear/damage, and lubricating bearings. Monitoring motor torque and drum alignment helps prevent operational failures.

Where are rotary trommel screens commonly applied?

Q: Which industries use rotary trommel screens extensively?

A: They're widely used in mining, waste recycling, agriculture, and composting. Applications include sorting aggregates, separating organic waste, and processing minerals or recycled construction materials.