- Introduction to Vibrating Screening Technology

- Technical Advantages of Modern Screening Systems

- Performance Comparison: Leading Industrial Brands

- Custom Engineering Solutions for Specific Needs

- Real-World Applications Across Industries

- Maintenance Best Practices for Longevity

- Future Outlook for Soil Separation Equipment

(vibrating topsoil screener)

Understanding Vibrating Topsoil Screener Fundamentals

Modern vibrating topsoil screener

s process 50-800 tons/hour while maintaining 95%+ material separation accuracy. These systems employ dual counter-rotational motors generating 900-1500 RPM vibrations, creating precise particle stratification. The inclined vibrating screen configuration (typically 15°-25°) enhances material flow rates by 30% compared to horizontal models.

Engineering Superiority in Particle Separation

Three critical innovations define premium-grade equipment:

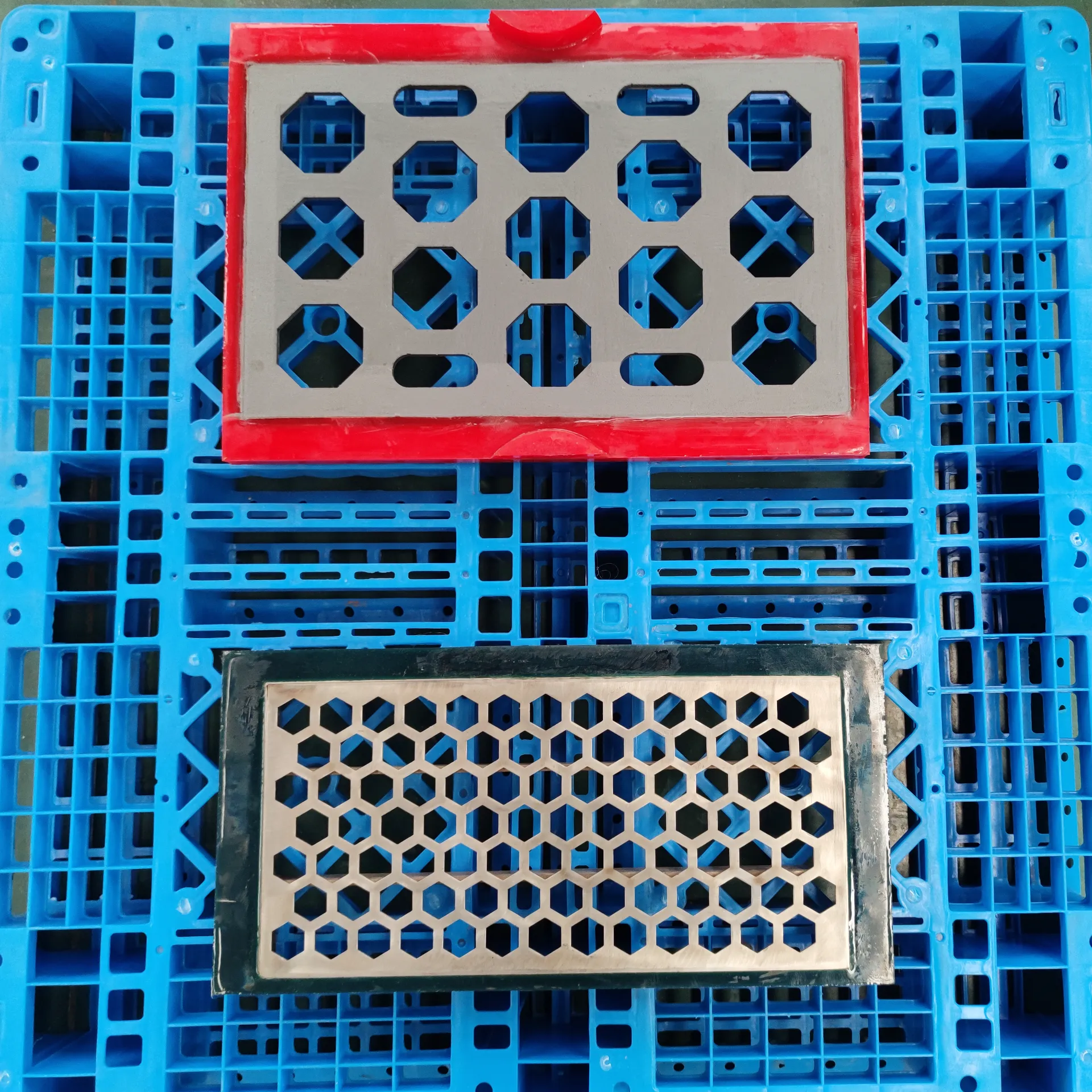

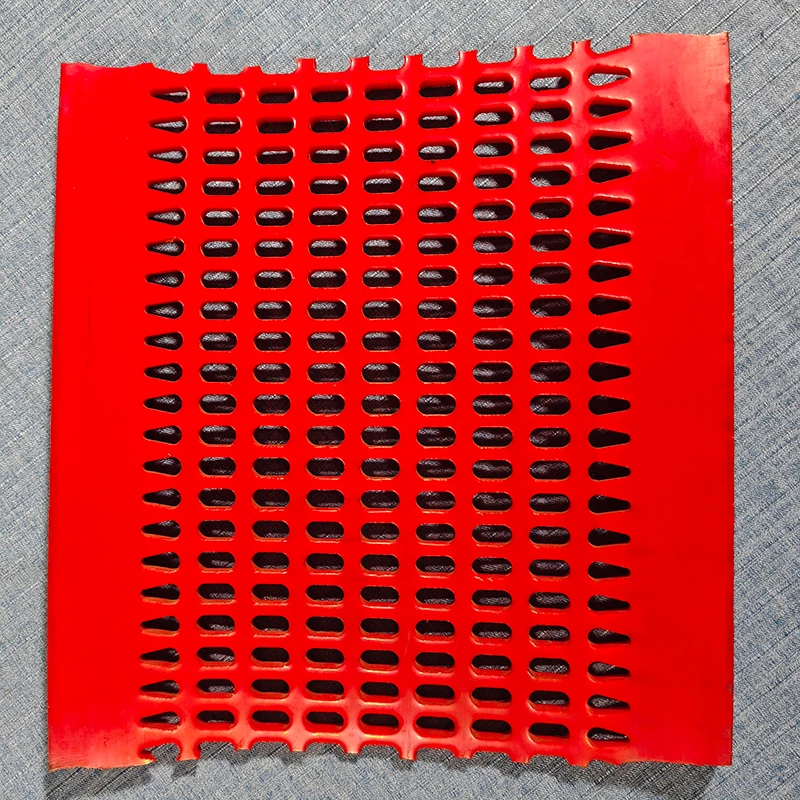

- Patented anti-blinding screen meshes (0.5mm-50mm aperture range)

- Variable-frequency drives allowing 10%-100% amplitude adjustment

- Modular deck systems supporting 1-5 screening layers

Field tests demonstrate 18-month continuous operation without component replacement when processing abrasive materials.

Industrial Screening Equipment Comparison

| Brand | Capacity (tph) | Screen Layers | Power Consumption | Warranty |

|---|---|---|---|---|

| X-Screener Pro | 650 | 4 | 18.5kW | 3 years |

| VibroMaster HD | 480 | 3 | 22kW | 2 years |

| TerraSeparator X3 | 720 | 5 | 26kW | 5 years |

Tailored Configuration Options

Specialized applications require customized parameters:

- Mining: 20mm tungsten-carbide screen coatings

- Agriculture: 3-5mm adjustable wire mesh

- Construction: 50Hz-60Hz frequency converters

Custom builds typically deliver 40% longer service life than standard models.

Operational Case Studies

Case 1: Colorado aggregate plant increased throughput from 280tph to 410tph through multi-frequency deck optimization.

Case 2: UK recycling facility reduced maintenance costs by 62% after switching to polyurethane screen panels.

Case 3: Australian mining operation achieved 99.2% separation efficiency using elliptical vibration patterns.

Preserving Equipment Performance

Routine maintenance protocols extend operational lifespan:

- Daily: Bearing temperature checks (≤65°C)

- Weekly: Bolt torque verification (350-400 N·m)

- Monthly: Screen tension measurement (5-6kN/m)

Advancing Vibrating Topsoil Screener Technology

Next-generation models integrate IoT sensors monitoring vibration harmonics (±0.05mm accuracy) and predictive maintenance algorithms reducing downtime by 75%. The global market for industrial vibrating screens is projected to grow at 6.8% CAGR through 2030, driven by automation in material processing sectors.

(vibrating topsoil screener)

FAQS on vibrating topsoil screener

Q: What is the primary application of a vibrating topsoil screener?

A: Vibrating topsoil screeners are mainly used to separate debris, rocks, and oversized materials from topsoil, ensuring a fine, uniform texture for landscaping or agricultural use.

Q: How does an industrial vibrating screen improve material processing?

A: Industrial vibrating screens use high-frequency vibrations to efficiently sort, grade, and separate bulk materials like aggregates, minerals, or recycled waste, reducing manual labor and processing time.

Q: What maintenance is required for an inclined vibrating screen?

A: Regularly check and tighten bolts, lubricate bearings, and inspect screen meshes for wear or damage to ensure optimal performance and longevity.

Q: What distinguishes a horizontal vibrating screen from an inclined vibrating screen?

A: Horizontal screens use linear vibrations for precise material stratification, while inclined screens rely on gravity and elliptical vibrations to move materials downward along the slope.

Q: Can vibrating topsoil screeners handle wet or sticky materials?

A: Yes, some models feature anti-clogging screen designs or water spray systems to manage moist or adhesive materials effectively during screening.