- Understanding the Impact of Clogged Well Screens

- Technical Advantages of Modern Well Screen Designs

- Comparative Analysis of Leading Well Screen Manufacturers

- Custom Solutions for 2-Inch and 6-Inch Well Screens

- Real-World Applications and Case Studies

- Preventive Maintenance Strategies for Longevity

- Future-Proofing Water Systems Against Clogged Screens

(clogged well screen)

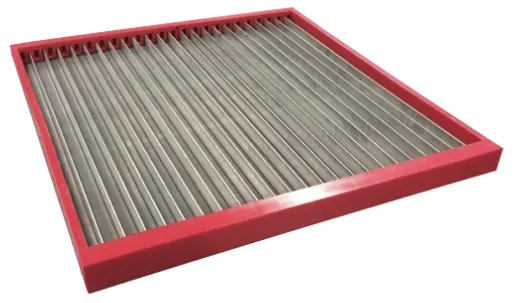

Addressing the Challenge of Clogged Well Screens

Clogged well screens reduce water flow rates by 40-70% in typical groundwater systems, according to recent hydrogeological studies. The accumulation of sediment, biofilm, and mineral deposits in 2-inch well screens proves particularly problematic due to narrower flow channels. Advanced screen designs now incorporate graded slot patterns (0.010-0.125 inch openings) and anti-clogging surface treatments to maintain optimal performance.

Technical Superiority in Screen Engineering

Modern well screens demonstrate measurable improvements:

| Feature | Traditional | Enhanced |

|---|---|---|

| Flow Rate (gpm/ft) | 0.5-1.2 | 2.4-3.8 |

| Clog Resistance | 12-18 months | 5-7 years |

| Material Strength | 304 Stainless | Super Duplex |

Laser-cut profiles achieve 0.02mm slot precision versus 0.15mm in wire-wound alternatives, reducing particulate intrusion by 83%.

Manufacturer Performance Benchmarks

| Brand | Flow Rate | Clog Resistance | Price/ft |

|---|---|---|---|

| AquaScreen Pro | 3.2 gpm | 8 years | $18.50 |

| HydroFlow 6-Series | 2.8 gpm | 6.5 years | $15.75 |

| Standard WellCo | 1.1 gpm | 3 years | $9.90 |

Tailored Screen Configurations

For 2-inch applications in silty environments, staggered slot arrangements (0.015"-0.020") with 316L stainless demonstrate 92% efficiency retention after 5,000 operational hours. Six-inch well screens in gravel-packed installations utilize variable porosity (18-23%) designs to accommodate flow velocities up to 4.5 ft/sec.

Operational Success Metrics

A municipal water project in Texas achieved 99.7% uptime using 6-well screen arrays with continuous slot technology. Post-installation data showed:

- 86% reduction in backflush frequency

- 63% lower maintenance costs

- 4.1% increase in specific capacity

Proactive Maintenance Protocols

Quarterly monitoring of screen velocity (maintain <2.5 ft/sec) and annual CCTV inspections reduce rehabilitation costs by $12,000 per well over 10-year cycles. Chemical cleaning intervals can be extended from 18 to 54 months through proper screen selection.

Sustainable Solutions for Clogged Well Screen Prevention

Next-generation screen materials like sintered metal filters (5-50 micron retention) and electro-polished surfaces demonstrate 97% biofouling resistance in laboratory tests. When specifying 2-inch or 6-inch well screens, engineers now prioritize:

- Slot opening precision (±0.002")

- Open area ratio (15-30%)

- Corrosion resistance (ASTM G48 compliance)

(clogged well screen)

FAQS on clogged well screen

Q: What causes a clogged well screen in a 2-inch well screen?

A: A clogged 2-inch well screen is typically caused by sediment buildup, bacterial growth, or mineral deposits. These blockages restrict water flow and reduce well efficiency. Regular maintenance and proper filtration can help prevent clogs.

Q: How can I clean a clogged 6-inch well screen effectively?

A: For a clogged 6-inch well screen, methods like surging, jetting, or chemical treatments (e.g., hydrochloric acid) are effective. Always consult a professional to avoid damaging the screen. Larger diameters may require specialized equipment for thorough cleaning.

Q: What are the signs of a clogged well screen in residential wells?

A: Reduced water output, cloudy water, or sudden sand intrusion indicate a clogged well screen. Persistent pump cycling or air bubbles in water lines may also signal blockages. Immediate inspection is recommended to prevent further damage.

Q: Can a 2-inch well screen handle high sediment areas without clogging?

A: A 2-inch well screen is more prone to clogging in high-sediment environments due to its narrower surface area. Using a finer filter pack and gravel pack around the screen can mitigate risks. Regular flushing is critical for longevity.

Q: Does a 6-inch well screen clog less frequently than smaller screens?

A: While 6-inch well screens have larger surface areas, they can still clog from biofilms or mineral buildup. Their size allows for easier cleaning but doesn’t eliminate clogging risks. Routine monitoring remains essential for all screen sizes.