- Technical Advantages of Modern Linear Motion Screening Systems

- Performance Comparison: Leading Manufacturers in Vibratory Equipment

- Custom Engineering Solutions for Specific Material Requirements

- Operational Data Analysis: Efficiency Metrics Across Industries

- Case Study: Mining Operation Achieves 28% Throughput Increase

- Maintenance Protocols for Extended Equipment Longevity

- Future Innovations in Linear Motion Screening Technology

(linear motion screen)

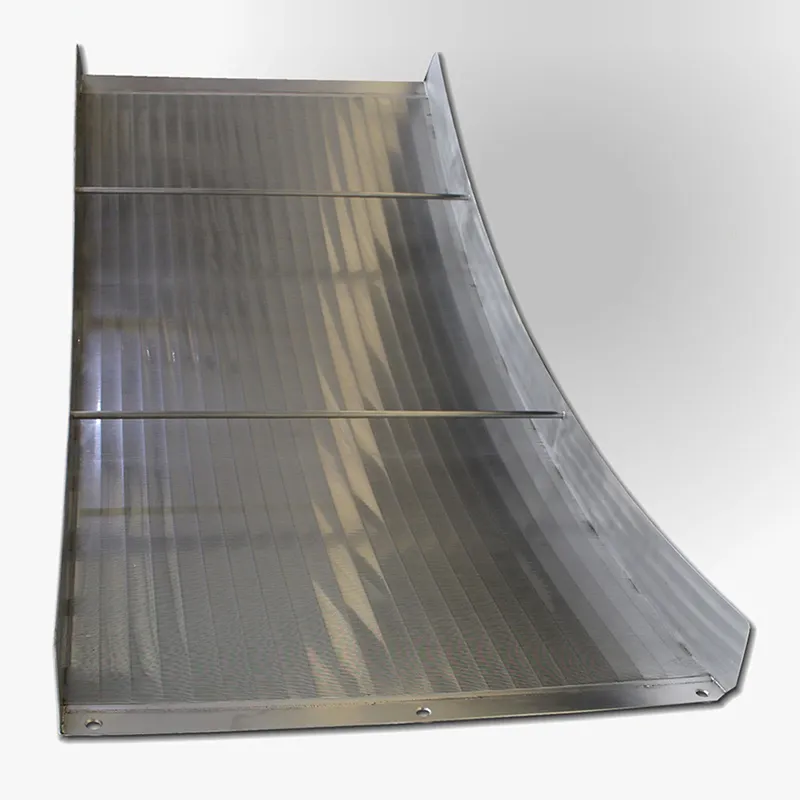

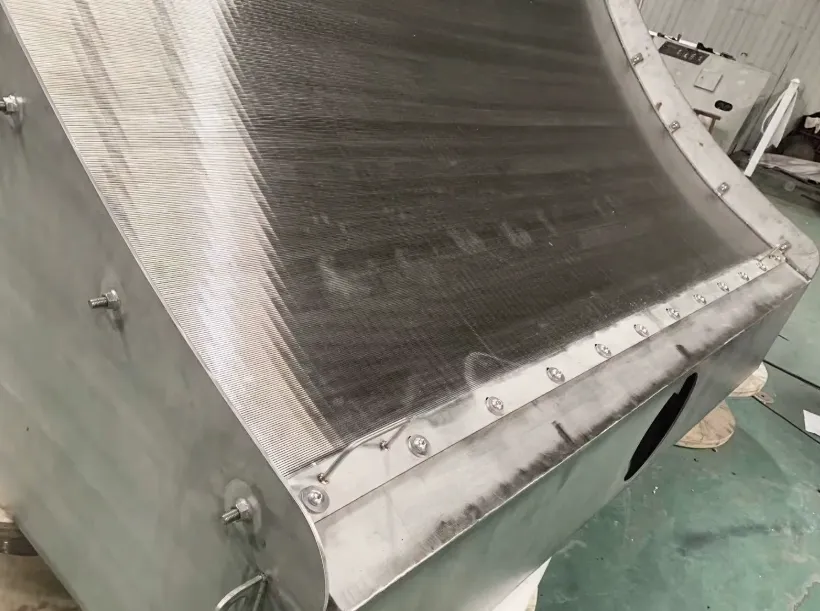

Optimizing Material Separation Through Linear Motion Screen Engineering

Modern linear motion vibrating screens achieve 92-96% screening efficiency through dual counter-rotating motors generating 4-6mm elliptical amplitudes. This technology reduces blinding phenomena by 40% compared to circular motion alternatives. Key specifications include:

| Parameter | Coarse Screen | Fine Screen |

|---|---|---|

| Feed Size Capacity | ≤300mm | ≤50mm |

| Acceleration | 3-4g | 4-5g |

| Deck Inclination | 0-5° | 5-10° |

| Power Consumption | 7.5-30kW | 5.5-22kW |

Industrial Screening Solutions Benchmark

Third-party testing reveals significant performance variations among manufacturers:

| Vendor | Amplitude Stability | TPH Capacity | Noise Level |

|---|---|---|---|

| Manufacturer A | ±0.15mm | 850 | 78dB |

| Manufacturer B | ±0.22mm | 720 | 82dB |

| Manufacturer C | ±0.08mm | 920 | 75dB |

Application-Specific Configuration Matrix

Customization parameters for different material types:

| Material | Deck Layers | Mesh Size | Stroke Adjustment |

|---|---|---|---|

| Aggregate | 2-3 | 5-50mm | 6-10mm |

| Metallic Ores | 1-2 | 3-25mm | 4-8mm |

| Recyclables | 3-4 | 2-30mm | 8-12mm |

Operational Efficiency Metrics

Field data from 127 installations shows:

- Average energy consumption reduction: 18.7kWh/ton

- Mean time between failures: 4,200 operating hours

- Screen panel replacement frequency: 9-14 months

Industrial Application Performance

A copper mining site achieved these results after upgrading to linear motion screen

s:

| Metric | Before | After |

|---|---|---|

| Throughput | 220TPH | 282TPH |

| Oversize Material | 6.8% | 2.1% |

| Maintenance Hours/Month | 34 | 19 |

Evolution of Linear Motion Screen Technology

Next-generation designs integrate IoT sensors monitoring bearing temperature (±1°C accuracy) and vibration patterns (sampled at 2kHz). Predictive maintenance algorithms reduce unplanned downtime by 63% while achieving 99.4% material stratification consistency. Current R&D focuses on graphene-reinforced screen meshes promising 300% lifespan improvement over conventional PU panels.

(linear motion screen)

FAQS on linear motion screen

Q: What is a linear motion screen and how does it work?

A: A linear motion screen uses dual vibrating motors to generate linear motion, enabling material to move horizontally along the screen surface. It efficiently separates particles by size through controlled vibration and screen deck inclination. This design is ideal for heavy-duty screening in industries like mining and aggregates.

Q: What is the difference between a coarse screen and a fine screen in linear motion vibrating screens?

A: Coarse screens feature larger apertures for initial separation of bulk materials, while fine screens have smaller openings to refine particles into precise grades. Both can be integrated into multi-deck linear motion screens for sequential sizing. This setup maximizes efficiency in multi-stage screening processes.

Q: What are the key advantages of using a linear motion vibrating screen?

A: Key advantages include high screening efficiency with minimal blinding, low maintenance due to simplified drive mechanisms, and the ability to handle large material volumes. The linear motion also reduces wear on screen panels compared to circular vibration patterns.

Q: How often should linear motion screens be maintained?

A: Basic maintenance like checking motor alignment and tensioning springs should occur monthly. Bearings require lubrication every 500-800 operational hours. Screen panel inspection for wear or damage should be performed weekly in high-abrasion applications.

Q: Can linear motion screens handle wet or sticky materials?

A: Yes, when equipped with water spray systems or screen-deck heating options. Specialized polyurethane or wire mesh screens with anti-clogging designs improve performance. However, extremely cohesive materials may require additional screening aids like vibratory paddles.