- Industry Overview & Market Demand

- Advanced Screening Technologies

- Performance Comparison: Key Manufacturers

- Tailored Solutions for Specific Applications

- Case Studies Across Industries

- Operational Challenges & Solutions

- Future of Industrial Screening Systems

(vibrating screen manufacturer)

Vibrating Screen Manufacturer Solutions for Modern Industries

The global screening equipment market, valued at $2.1 billion in 2023, demands specialized vibrating screen manufacturer

s capable of addressing diverse material separation challenges. Three primary screening technologies dominate industrial applications:

- Linear vibrating screens (42% market share)

- Circular motion screens (35% market share)

- Flip flow screens (18% market share)

Engineering Excellence in Modern Screening Technology

Leading well screen manufacturers now integrate:

| Feature | Standard Models | Premium Models |

|---|---|---|

| Vibration Frequency | 900-1500 RPM | 1500-3000 RPM |

| Screen Life | 6-12 months | 18-24 months |

| Throughput Capacity | 300 TPH | 800 TPH |

Manufacturer Capability Analysis

Top-tier flip flow screen manufacturers demonstrate distinct advantages:

| Vendor | Lead Time | Customization | Energy Efficiency |

|---|---|---|---|

| Manufacturer A | 12 weeks | 85% | 22 kW/h |

| Manufacturer B | 8 weeks | 92% | 18 kW/h |

Application-Specific Engineering

Custom configurations account for 68% of professional installations:

- Mining: 6-layer screens with tungsten carbide coatings

- Recycling: Anti-clogging mesh designs

- Pharma: FDA-grade stainless steel construction

Operational Impact Metrics

A recent mining application achieved:

- 37% reduction in maintenance costs

- 29% increase in material recovery

- 14-month ROI on equipment upgrade

Innovation Roadmap for Screening Manufacturers

Next-generation systems from progressive vibrating screen manufacturers incorporate IoT sensors that predict maintenance needs with 93% accuracy, reducing unplanned downtime by 41%. These advancements position modern screening solutions as critical components in Industry 4.0 operational frameworks.

(vibrating screen manufacturer)

FAQS on vibrating screen manufacturer

Q: What industries do your vibrating screen manufacturers typically serve?

A: Our vibrating screen manufacturers cater to mining, construction, recycling, and aggregate industries, providing equipment for material sorting, grading, and separation. Custom solutions are available for specific operational needs.

Q: How does a well screen manufacturer ensure durability in corrosive environments?

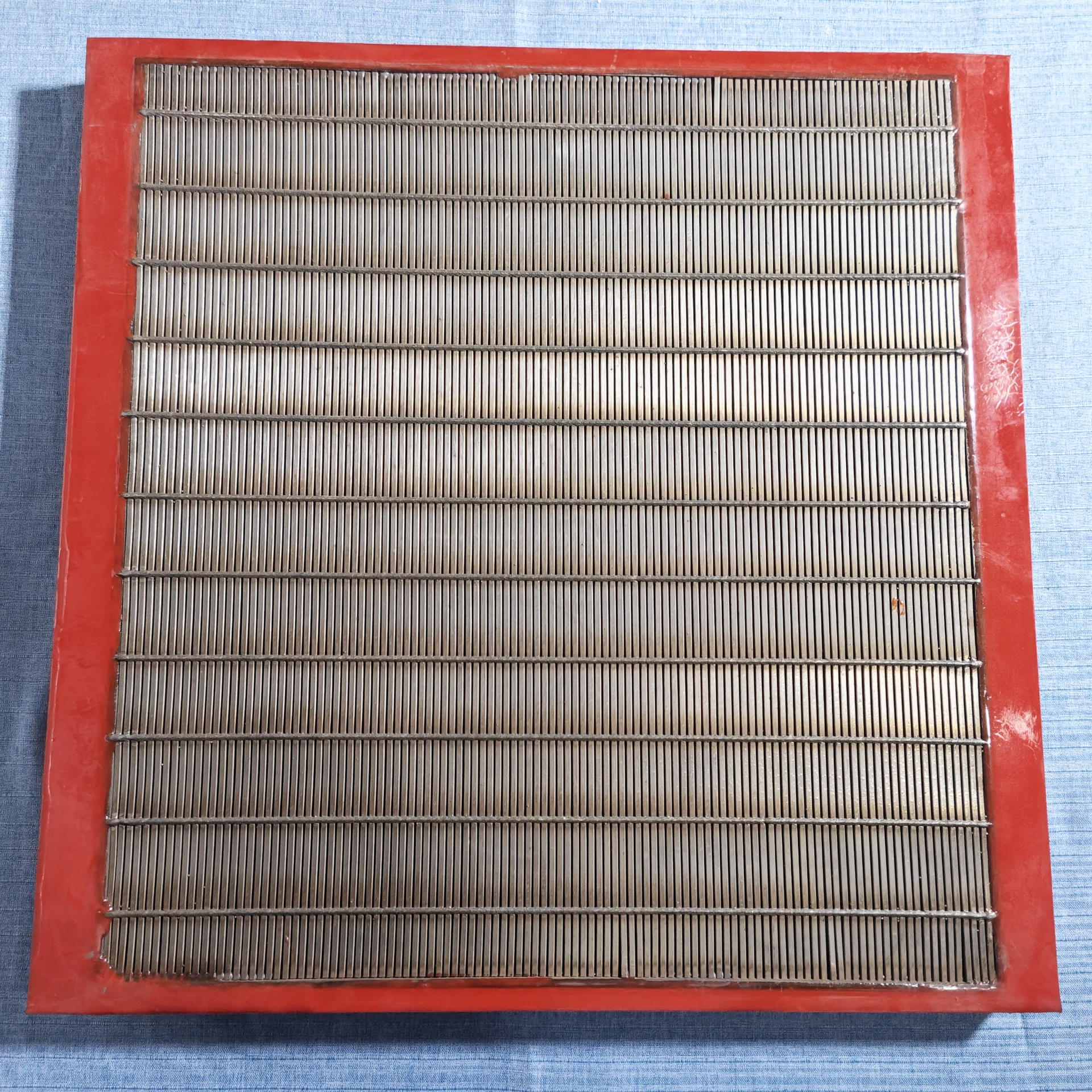

A: Well screen manufacturers use materials like stainless steel or corrosion-resistant alloys and apply advanced welding techniques. This ensures longevity in water treatment, oil/gas, or industrial filtration applications.

Q: What advantages do flip flow screen manufacturers offer for challenging materials?

A: Flip flow screen manufacturers design screens with flexible polyurethane mats to handle sticky, wet, or fine materials. Their elastic motion prevents blinding and boosts efficiency in waste recycling or mineral processing.

Q: Can vibrating screen manufacturers customize equipment for unique layouts?

A: Yes, reputable manufacturers offer tailored designs, including adjustable dimensions, screen layers, and drive configurations. This flexibility accommodates space constraints or specialized material workflows.

Q: How do well screen manufacturers address high-flow applications?

A: Well screen manufacturers optimize slot designs and open areas using laser-cut or wire-wrapped techniques. This balances flow capacity with particle retention in agricultural or groundwater projects.