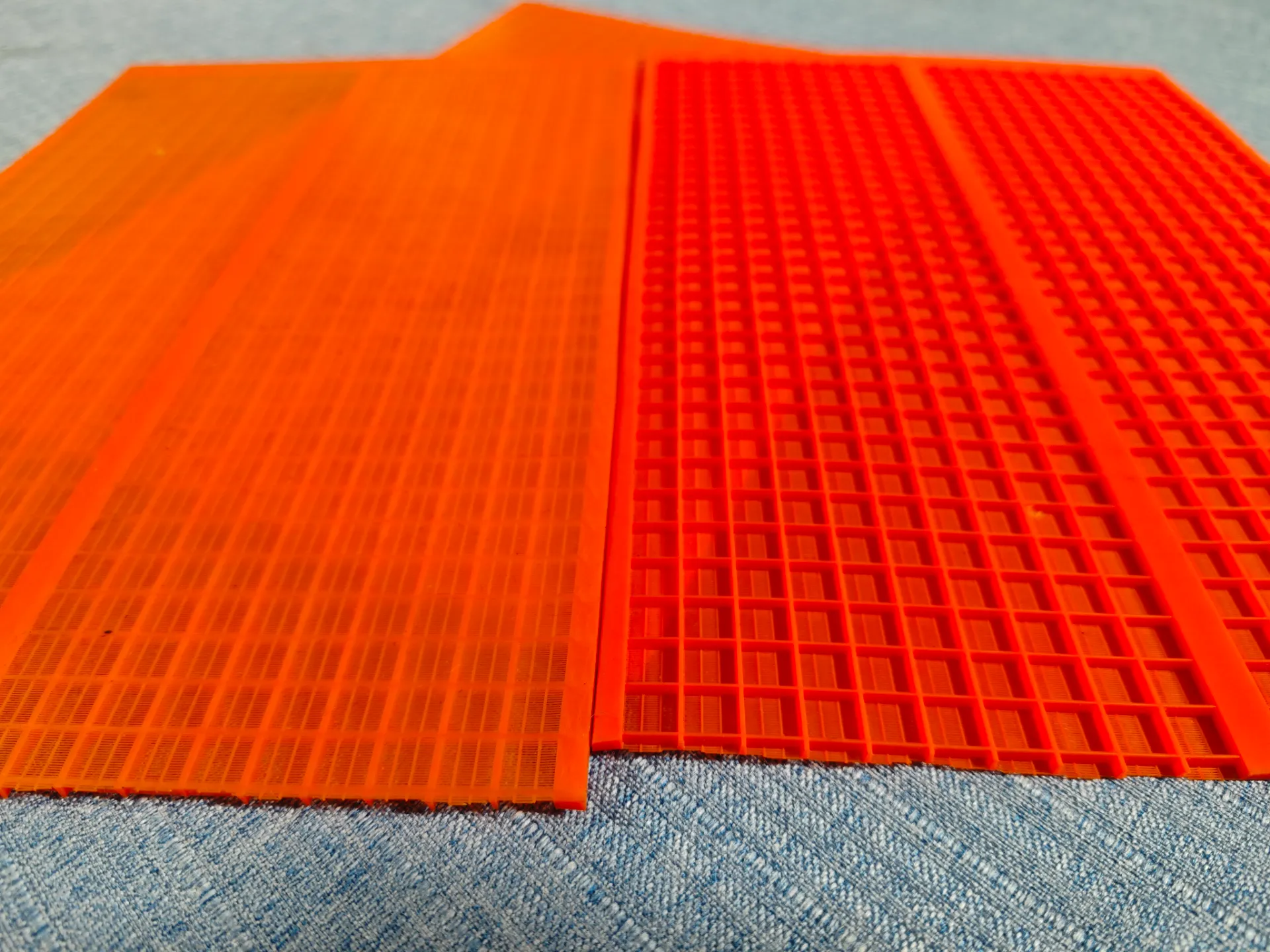

- Introduction to Wedge Wire Screen Technology

- Analyzing Technical Advantages in Filtration Efficiency

- Market Comparison: Pricing vs. Performance

- Custom Solutions for Industrial Challenges

- Case Studies: Real-World Applications

- Material Durability & Operational Longevity

- Why Partner with a Specialized Wedge Wire Screen Manufacturer

(wedge wire screen factory)

Understanding the Role of a Wedge Wire Screen Factory

Wedge wire screens serve as critical components across industries requiring precision filtration, from water treatment plants to mining operations. A professional wedge wire screen factory

combines advanced manufacturing techniques with metallurgical expertise to produce screens with consistent slot accuracy (typically ±0.02mm). Industry data reveals that optimized production processes can increase screen longevity by 40-60% compared to conventional methods.

Technical Superiority in Filtration Systems

Modern wedge wire screens demonstrate measurable performance improvements:

- 98.7% particle retention accuracy in 50-500 micron ranges

- 30% higher flow rates than punched plate alternatives

- 316L stainless steel variants withstand temperatures up to 550°C

These technical parameters directly impact operational costs, with proper screen selection reducing maintenance frequency by 25-35%.

Cost-Benefit Analysis Across Suppliers

| Manufacturer | Price Range (USD/m²) | Lead Time | Customization |

|---|---|---|---|

| Standard Suppliers | $120-$180 | 8-12 weeks | Limited |

| Specialized Factories | $150-$220 | 4-6 weeks | Full CAD Support |

While specialized manufacturers show slightly higher wedge wire screen price points, their 67% faster production cycles and engineering support justify the investment through reduced downtime.

Tailored Engineering Solutions

Custom configurations address specific operational needs:

- Variable wire thickness (2-12mm) for pressure resistance

- Non-standard screen curvatures (5-180° bend radius)

- Hybrid materials like duplex stainless steel for corrosive environments

Documented Performance in Critical Applications

A mining operation achieved 92% sediment capture efficiency after upgrading to wedge wire screens, reducing filter replacement costs by $18,000 annually. Water treatment plants report 15-20% energy savings through optimized flow dynamics.

Material Science Behind Screen Longevity

Accelerated aging tests show:

- 0.03mm/year corrosion rate in pH 2-12 environments

- 120% higher fatigue resistance than woven alternatives

- UV-stable polymer coatings maintaining integrity for 10+ years

Strategic Advantages of Certified Wedge Wire Screen Manufacturers

Partnering with ISO 9001-certified producers ensures compliance with international filtration standards (AWWA, ASTM). Technical audits reveal that certified facilities maintain 99.4% product consistency versus 82-88% in generic workshops. This quality assurance translates to 3-5 year extended service life across installations.

(wedge wire screen factory)

FAQS on wedge wire screen factory

Q: What factors influence the wedge wire screen price?

A: The price depends on material type (e.g., stainless steel), screen dimensions, slot size, and customization requirements. Bulk orders or specialized designs may also affect costs.

Q: How to choose a reliable wedge wire screen manufacturer?

A: Prioritize manufacturers with certifications (e.g., ISO), proven industry experience, and positive client reviews. Request samples to evaluate quality and precision firsthand.

Q: What industries commonly use products from a wedge wire screen factory?

A: Common industries include water treatment, mining, agriculture, and oil/gas. These sectors rely on wedge wire screens for filtration, separation, and durability in harsh environments.

Q: Can a wedge wire screen factory provide custom designs?

A: Yes, most factories offer tailored solutions for slot sizes, shapes, and materials. Share your specifications for filtration efficiency, pressure resistance, or corrosion needs.

Q: What materials are used in wedge wire screen production?

A: Common materials include 304/316 stainless steel for corrosion resistance, carbon steel for durability, and exotic alloys for extreme conditions. Material choice impacts cost and performance.