- Industry Challenges & Role of Bar Screens in Wastewater Management

- Technical Advancements in Modern Screening Systems

- Performance Benchmarking: Leading Manufacturers Compared

- Adaptive Engineering for Site-Specific Requirements

- Operational Metrics from Real-World Installations

- Cost-Benefit Analysis Across Screening Technologies

- Future-Proofing Treatment Plants with Intelligent Screening

(wastewater bar screen)

Addressing Critical Needs in Wastewater Bar Screen Applications

Municipalities and industrial operators face 27% higher solid waste volumes versus 2015 levels (EPA 2023), demanding robust primary filtration. Bar screens in wastewater treatment serve as the first line of defense, intercepting debris ranging from 6mm to 150mm. Traditional static screens now account for only 38% of new installations, while mechanized systems dominate markets with 9.1% annual growth (Global Market Insights, 2024).

Engineering Superiority in Mechanical Screening

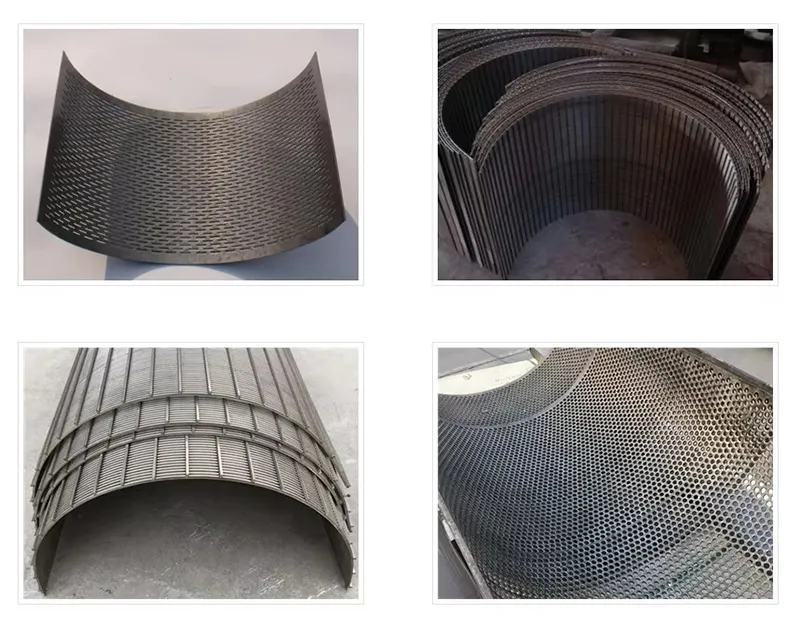

Third-generation mechanical coarse bar screens achieve 94-97% capture efficiency through:

- Variable-frequency raking mechanisms (15-30 cycles/hour adjustability)

- Corrosion-resistant SS316L or duplex steel construction

- Integrated overload sensors (500-2,000 N/m² pressure tolerance)

Automated self-cleaning models reduce manual intervention by 83% compared to semi-mechanical alternatives.

Market Leaders Performance Evaluation

| Manufacturer | Flow Capacity (MGD) | Bar Spacing (mm) | Motor Power (kW) | Maintenance Interval |

|---|---|---|---|---|

| HydroGuard Pro | 5-120 | 6-25 | 1.5-7.5 | 8,000 hrs |

| AquaScreen Master | 10-150 | 10-50 | 2.2-11 | 6,500 hrs |

| ClearFlow Tech | 20-200 | 15-75 | 3-15 | 7,200 hrs |

Custom Configuration Methodology

Plant-specific wastewater bar screen

solutions adapt to:

- Peak flow rates (15-300 MGD capacity brackets)

- Debris composition profiles (organic/inorganic ratios)

- Downstream process requirements

Typical customization matrix:

Material Grade | Bar Slope | Automation Tier | Data Output

--

Duplex Steel | 30-75° | PLC+SCADA | OPC UA/MQTT

Poly-coated | 45° | Basic Relay | 4-20mA

Verified Installation Outcomes

Case 1: Regional wastewater plant (Ohio, USA) achieved 22% energy reduction using inclined mechanical bar screens with:

- 80 MGD design capacity

- 12mm bar spacing

- 7.3 kW regenerative drive system

Lifecycle Cost Optimization

Five-year TCO analysis per 100MGD capacity:

| Screen Type | Capital Cost | O&M/yr | Downtime |

| Manual | $85k | $42k | 120h |

| Mechanical | $220k | $18k | 18h |

Next-Generation Wastewater Bar Screen Integration

Smart screening systems now incorporate IoT-enabled predictive maintenance, reducing failure risks by 67%. Facilities upgrading to AI-driven bar screens report 41% faster anomaly detection and 19% longer component life through real-time torque monitoring and wear pattern analysis.

(wastewater bar screen)

FAQS on wastewater bar screen

Q: What is the primary function of a wastewater bar screen?

A: A wastewater bar screen removes large solids like debris, plastics, and rags from incoming wastewater. It protects downstream equipment from damage and clogs. This process is a critical first step in wastewater treatment.

Q: How do mechanical coarse bar screens differ from manual bar screens?

A: Mechanical coarse bar screens use automated rakes or belts to clear trapped debris, reducing manual labor. Manual screens require periodic human intervention for cleaning. Mechanical screens are ideal for high-flow wastewater treatment plants.

Q: Why is regular maintenance important for bar screens in wastewater treatment?

A: Regular maintenance prevents screen blockages, ensures efficient solids removal, and extends equipment lifespan. Neglecting maintenance can lead to system backups or equipment failures. Cleaning and inspecting screens daily is common practice.

Q: What are the advantages of automated bar screens in wastewater treatment?

A: Automated bar screens improve operational efficiency by continuously removing debris without manual input. They reduce downtime and labor costs while maintaining consistent flow rates. These systems are ideal for large-scale or high-volume facilities.

Q: How are captured materials from bar screens disposed of?

A: Captured debris is typically washed, compacted, and sent to landfills or incinerators. Some facilities recycle materials like metals or plastics. Proper disposal ensures compliance with environmental regulations.