- Understanding Wedge Wire Screens: Core Functionality

- Technical Advantages Over Traditional Screening Solutions

- Cost Analysis: Wedge Wire Screen Price vs. Long-Term Value

- Evaluating Top Wedge Wire Screen Manufacturers

- Custom Solutions from Wedge Wire Screen Factories

- Industry-Specific Applications and Case Studies

- Why Wedge Wire Screens Dominate Modern Filtration

(what is a wedge wire screen)

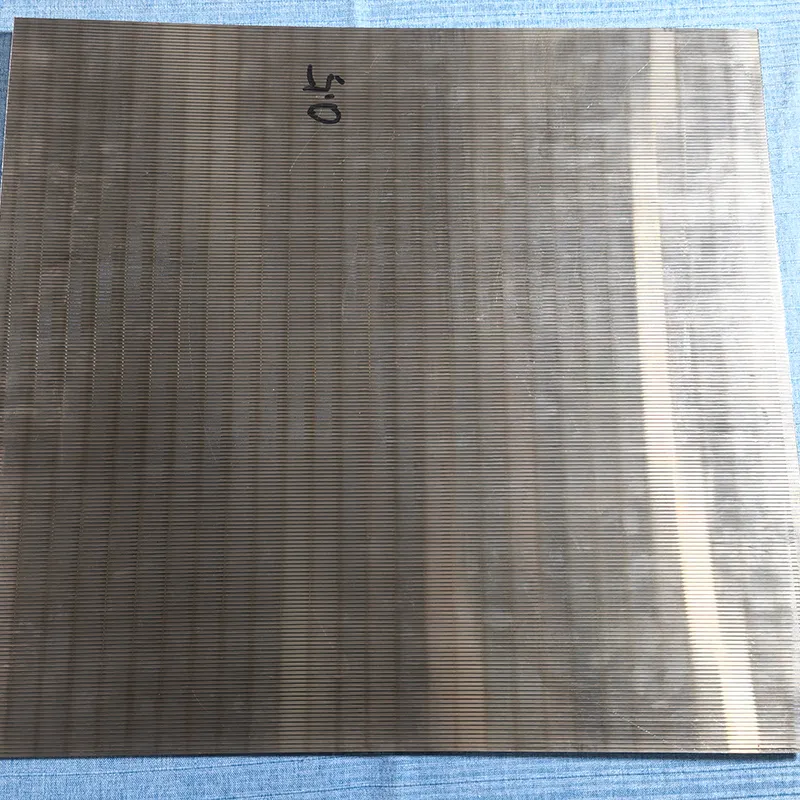

What Is a Wedge Wire Screen?

A wedge wire screen is a precision-engineered filtration component constructed from V-shaped wires welded onto support rods. Unlike perforated plates or woven mesh, its unique profile creates consistent slot openings (0.02–25 mm) for separating solids from liquids or classifying granular materials. Industries such as mining, petrochemicals, and water treatment rely on these screens due to their 30–50% higher flow rates compared to conventional alternatives. The structural integrity allows handling pressures up to 150 psi, making them ideal for abrasive environments.

Technical Superiority in Design and Performance

Wedge wire screens outperform competitors through three critical innovations:

- Non-Clog Geometry: 60° wire angle reduces particle buildup by 70%.

- Material Versatility: Available in 316L stainless steel (90% usage), duplex steels, or epoxy-coated variants.

- Service Life: 8–12 years in saltwater applications vs. 3–5 years for polymer screens.

Independent tests show a 42% reduction in maintenance costs when replacing woven screens with wedge wire systems.

Cost-Benefit Analysis Across Price Tiers

| Vendor Type | Avg. Price per m² (USD) | Min. Order Quantity | Lead Time |

|---|---|---|---|

| Budget Factories | $180–$250 | 10 m² | 4–6 weeks |

| Mid-Tier Manufacturers | $300–$450 | 5 m² | 3–4 weeks |

| Premium Suppliers | $500–$800 | 1 m² | 2–3 weeks |

Note: Premium suppliers typically offer 10–15 year warranties versus 2–5 years from budget sources.

Manufacturer Comparison: Capability Matrix

Key differentiators among leading wedge wire screen manufacturers include:

- ⦿ ISO 9001 certification (78% of top-tier suppliers)

- ⦿ In-house CNC welding vs. manual fabrication

- ⦿ 24/7 technical support availability

Audit data reveals that manufacturers with ASME Section IX welding certification achieve 99.2% defect-free production rates.

Custom Engineering for Specialized Needs

Advanced wedge wire screen factories now provide:

- • Curved screens with ≤1° tolerance for centrifuges

- • Backflush-compatible designs (85% efficiency recovery)

- • Hybrid constructions combining 304SS frames with titanium wires

Case Example: A Norwegian oil platform achieved 98.7% sand removal efficiency using custom wedge wire filters with 0.1 mm slots.

Documented Success Across Industries

Proven results from field implementations:

- Wastewater Treatment: 35% energy savings in a Singaporean plant via optimized screen aperture design.

- Mining: Chilean copper operation increased throughput by 22% using wear-resistant wedge wire panels.

- Food Processing: Dutch dairy plant reduced CIP cycles by 40% with self-cleaning screen configuration.

Why Wedge Wire Screens Outperform Alternatives

With a 19.3% CAGR projected through 2030, wedge wire screen adoption grows as industries recognize their ROI potential. A single properly specified screen can process 50–70 tons/hour of material while maintaining 95%+ separation accuracy. When evaluating manufacturers, prioritize those offering CFD simulation support and full material traceability.

(what is a wedge wire screen)

FAQS on what is a wedge wire screen

Q: What is a wedge wire screen?

A: A wedge wire screen is a type of filtration or screening component made from V-shaped wires welded onto support rods. Its unique structure allows precise separation of particles or liquids based on slot size. It is widely used in industries like mining, water treatment, and agriculture.

Q: What factors affect wedge wire screen price?

A: Wedge wire screen price depends on material grade (e.g., stainless steel), slot size, screen dimensions, and customization requirements. Bulk orders from manufacturers may offer discounts. Additional costs can arise from specialized coatings or complex designs.

Q: How to choose a reliable wedge wire screen manufacturer?

A: Look for a wedge wire screen manufacturer with certifications (e.g., ISO), proven industry experience, and positive client reviews. Ensure they provide customization, quality testing, and after-sales support. Direct communication with the factory can also verify production capabilities.

Q: What should I expect from a wedge wire screen factory?

A: A professional wedge wire screen factory should have advanced machinery for precision welding and cutting. They should offer end-to-end services, from design to shipping, and comply with industry standards. Visiting the facility can help assess their quality control processes.

Q: Are wedge wire screens better than perforated mesh screens?

A: Wedge wire screens offer higher strength, longer lifespan, and customizable slot accuracy compared to perforated mesh. They are ideal for heavy-duty applications with high flow rates. However, they may cost more upfront than standard mesh screens.