(rotary screen wastewater)

Rotary Screening Systems for Efficient Wastewater Management

Rotary screening technology has transformed industrial and municipal wastewater pretreatment. This comprehensive guide examines:

- Performance metrics and removal efficiency data

- Technical advantages over static screening systems

- Comparative analysis of leading manufacturers

- Custom engineering solutions by sector

- Material composition and durability factors

- Operation and maintenance considerations

- Industry-specific application case studies

Performance Metrics in Solid Separation

Rotary drum screens demonstrate measurable advantages in pretreatment efficiency. Field data shows:

- 93-97% TSS removal for particles >2mm at flow rates up to 80,000 m³/day

- 50% reduction in downstream BOD loading compared to bar screens

- 30-45% lower headloss than static screens maintaining equal flow capacity

Performance varies based on rotational speed (typically 4-15 RPM) and screen aperture selection. Municipal installations handling 15 MGD achieve capture rates exceeding 4 tons/day of screenings.

Engineering Advantages in Waste Stream Processing

Modern rotary trommel designs incorporate features that address common wastewater challenges:

- Self-cleaning mechanisms utilizing spray bars operating at 60-80 PSI eliminate blinding

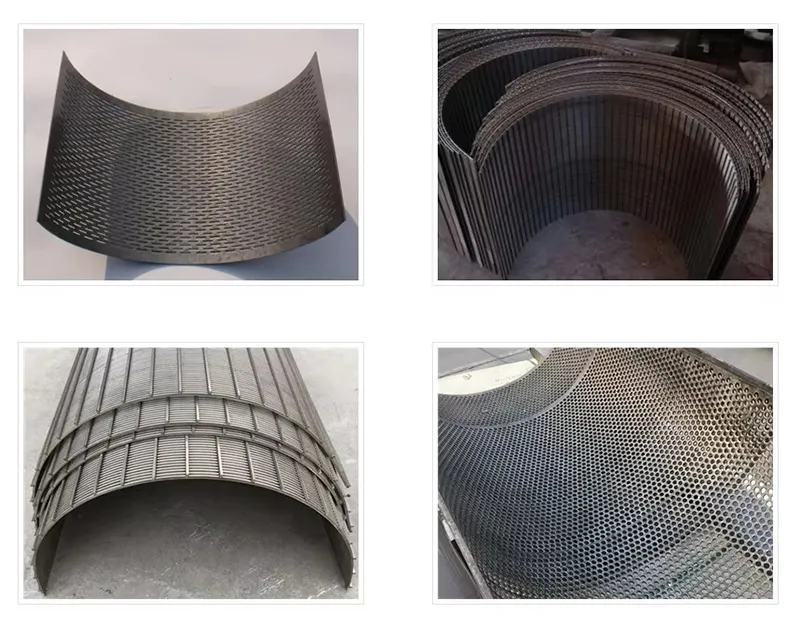

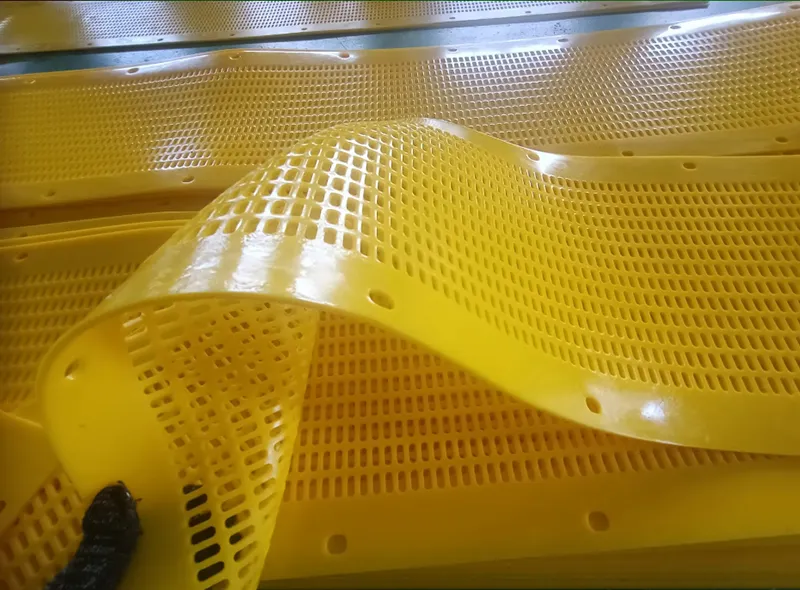

- Corrosion-resistant construction featuring 316L stainless steel or fiberglass-reinforced polymer

- Low-torque drum drives consuming only 0.75-5 kW depending on scale

Angled screen drums between 2-5 degrees utilize gravity for solids transport while wedge wire panels (0.5-6mm openings) prevent fiber wrapping. Dual-drum configurations handle peak flows up to 1800 l/s with negligible bypass.

Industrial Solutions Providers Comparison

| Manufacturer | Screen Media Options | Max Flow Rate | Drive Mechanism | Specialized Models |

|---|---|---|---|---|

| Hydro-Dyne Engineering | Perforated plate, wedge wire | 27,000 GPM | Submerged gear motor | High-temperature food processing units |

| Screw Tech International | Wedge wire, woven mesh | 15,000 GPM | Chain & sprocket | Off-grid solar powered units |

| JWC Environmental | Punched plate, profile bars | 38,000 GPM | Direct gear drive | Marine-deployed systems |

Sector-Specific Engineering Configurations

Application requirements dictate distinct rotary screen adaptations:

- Municipal: 1.5-3mm screens with 40° drum angles for sludge volumes between 5-25 dry tons/day

- Food Processing: CIP-compatible spray systems handling 7-12% solids waste streams

- Pulp & Paper: Abrasion-resistant tungsten-carbide coated drums processing 500-2000 ft³/min fiber waste

Specialized seals maintain efficiency when handling pH levels from 2.5-11 while hydraulic retention times range from 30-90 seconds depending on organic load.

Industrial Deployment Success Stories

Textile Manufacturer: Implementing a 2mm rotary drum screen wastewater system reduced downstream clarifier cleaning frequency from weekly to quarterly while recovering 24 tons/month of reusable fiber.

Regional Wastewater Authority: Retrofitting plants with rotary trommel screen wastewater technology decreased processing costs by $18,000/month and screening transport expenses by 62%.

Seafood Processor: A customized rotary screen wastewater

solution featuring extra-spray zones handles 85 GPM flow with particle retention down to 1mm.

Rotary Trommel Screens for Future-Ready Wastewater Infrastructure

These systems establish robust pretreatment foundations, especially crucial as regulations require removal of microplastics and increased solids capture. With operational lifespans exceeding 15 years, rotary screen wastewater technology delivers unmatched return on investment and operational reliability for municipal and industrial installations.

(rotary screen wastewater)

FAQS on rotary screen wastewater

Here are 5 HTML-formatted FAQs focusing on rotary screen wastewater treatment systems:Q: What is a rotary screen in wastewater treatment?

A: A rotary screen is a mechanical filtration device used in wastewater treatment plants to remove solids and debris from influent streams. It features a rotating drum with perforated or mesh screens that capture suspended particles while allowing liquid to pass through. This equipment serves as crucial preliminary treatment protecting downstream processes.

Q: How does a rotary drum screen work for wastewater filtration?

A: Wastewater flows into the rotating drum where gravity and screen apertures separate solids from liquids. Captured debris is lifted to the drum's top as it rotates and falls into a collection trough via gravity. The self-cleaning mechanism ensures continuous operation with minimal clogging.

Q: What are key advantages of using rotary trommel screens for wastewater?

A: Rotary trommel screens provide high-flow capacity with minimal headloss and low energy consumption. Their robust construction handles heavy solid loads while the tumbling action prevents blinding and reduces maintenance needs. These characteristics make them ideal for municipal and industrial pretreatment applications.

Q: What maintenance does a rotary screen wastewater system require?

A: Regular inspections of screen integrity, spray nozzles, and bearing lubrication are essential maintenance tasks. Monthly cleaning of internal components and periodic replacement of worn screen panels prevents operational failures. These proactive measures typically maintain 85-95% operational efficiency.

Q: How do rotary screens compare to static screens in wastewater treatment?

A: Rotary screens handle higher flow rates with finer filtration (down to 0.25mm) compared to static screens. Their automated cleaning eliminates manual raking requirements and reduces labor costs. However, rotary systems require power input and have higher initial investment than passive screening alternatives.