This blog provides a comprehensive analysis of stainless steel well screens, focusing on pricing factors, technical advantages, and industry applications. Below is a structured overview of the content:

- Introduction to stainless steel well screens and their role in water systems

- Technical advantages over alternative materials

- Market comparison: Leading manufacturers and pricing models

- Customization options for diverse project requirements

- Real-world applications and performance data

- Key factors influencing stainless steel well screen price

s - Final recommendations for cost-effective procurement

(stainless steel well screen price)

Understanding the Value of Stainless Steel Well Screens in Modern Water Systems

Stainless steel well screens are critical components in water extraction systems, offering unmatched durability in corrosive environments. With a global market growth rate of 6.2% CAGR (2023–2030), demand is driven by infrastructure upgrades and agricultural needs. These screens withstand pressures up to 2,500 PSI and temperatures ranging from -50°F to 1,000°F, outperforming PVC or carbon steel alternatives by 3–5x in lifespan.

Technical Superiority in Harsh Environments

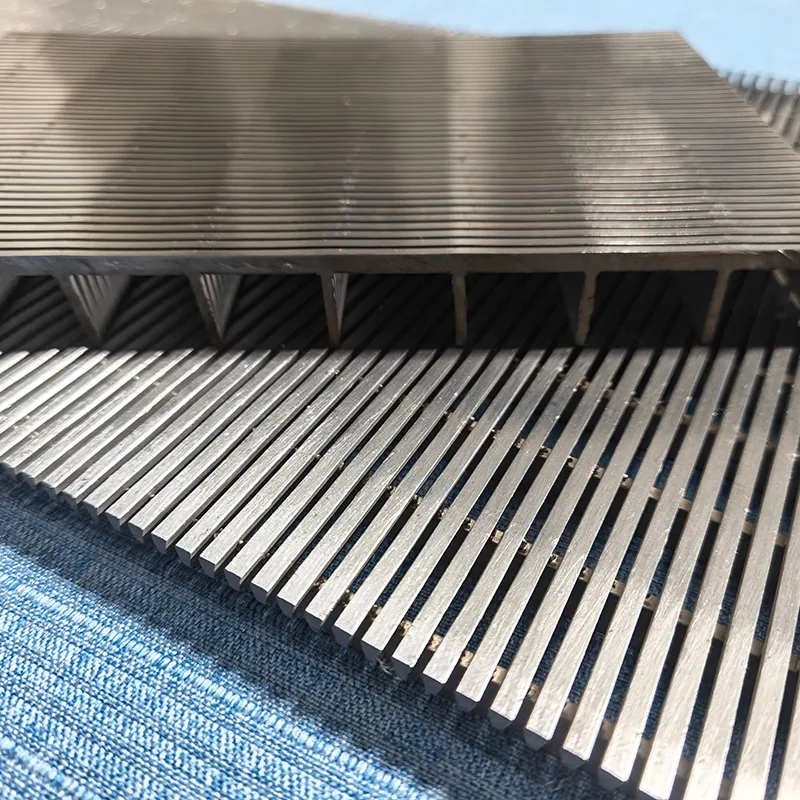

Grade 304/316 stainless steel screens dominate 78% of industrial applications due to:

- Corrosion resistance: 0.002mm/year erosion rate in saline water

- Structural integrity: 85,000 psi tensile strength

- Maintenance reduction: 40% lower lifecycle costs vs. polymer screens

Manufacturer Comparison: Pricing and Specifications

| Brand | Price Range (per linear foot) | Material Grade | Minimum Order |

|---|---|---|---|

| AquaScreen Pro | $12.50–$18.75 | 316L | 500 ft |

| HydroFlow Industries | $9.80–$15.20 | 304 | 1,000 ft |

| TerraWell Solutions | $14.30–$22.40 | Duplex 2205 | 250 ft |

Tailored Solutions for Specific Projects

Customization parameters significantly affect stainless steel well screen prices:

- Slot size: 0.010" to 0.125" (±0.002" tolerance)

- Diameter: 2" to 24" (standard) / up to 48" (custom)

- Length: 10' segments (typical) vs. continuous 20' rolls

Lead times range from 2–6 weeks, with 15–25% cost premiums for urgent orders.

Performance Metrics in Actual Installations

Case Study 1: Agricultural irrigation system (Nebraska, 2022)

- Screen type: 316 stainless, 0.040" slots

- Flow rate: 450 GPM sustained over 18 months

- Sediment reduction: 92% vs. previous carbon steel system

Critical Determinants of Screen Pricing

Four primary factors impact stainless steel well screen prices:

- Material costs (60–70% of total): $3.20/lb (304) to $5.45/lb (2205 duplex)

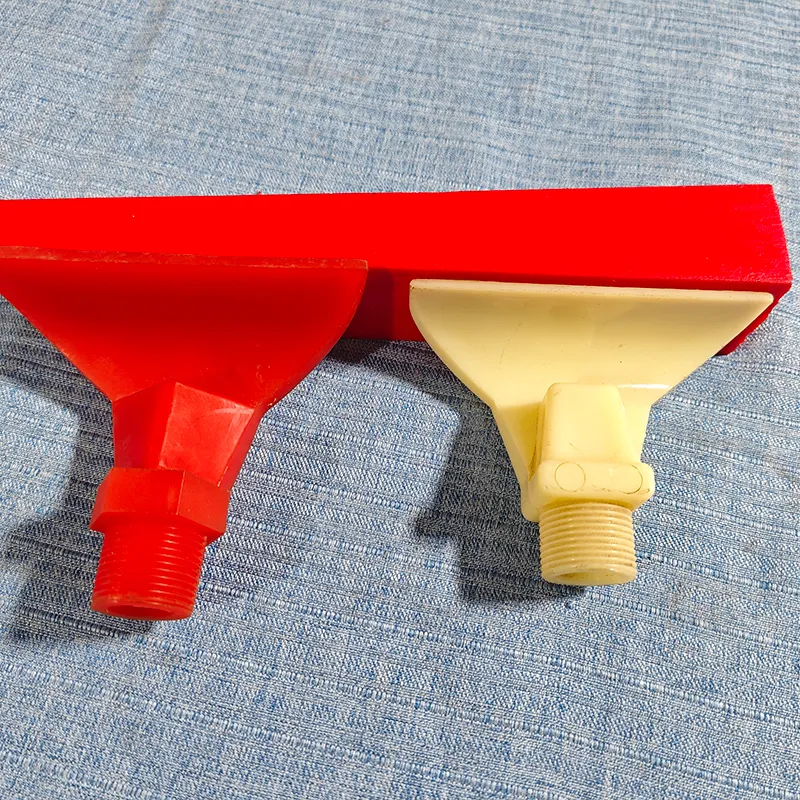

- Manufacturing complexity: Laser-cut slots add $2.75/ft vs. $1.20/ft for punched

- Order volume: 12–18% discounts for 5,000+ ft orders

- Certifications: NSF-61 approval increases costs by 8–12%

Why Invest in Stainless Steel Well Screens for Long-Term Water Solutions?

Despite higher initial costs (15–30% premium over alternatives), stainless steel well screens demonstrate 10–15 year service life with proper maintenance. The average ROI period is 3.8 years, considering reduced downtime and replacement frequency. For projects requiring reliability in challenging conditions, stainless steel remains the economically rational choice.

(stainless steel well screen price)

FAQS on stainless steel well screen price

Q: What factors influence the price of stainless steel well screens?

A: The price depends on material grade (e.g., 304 or 316 stainless steel), slot size, screen diameter/length, and manufacturing complexity. Custom designs or additional coatings may also increase costs.

Q: How does a stainless steel well screen compare to other materials in cost?

A: Stainless steel well screens are typically more expensive than PVC or carbon steel options but offer superior corrosion resistance and durability, reducing long-term replacement costs.

Q: Are stainless steel water well screens priced per foot or as a complete unit?

A: Most suppliers price stainless steel well screens per linear foot, with total costs calculated based on required length, diameter, and specifications. Custom orders may have fixed-unit pricing.

Q: Does slot size affect stainless steel well screen pricing?

A: Yes, smaller or specialized slot sizes require precise laser-cutting or welding techniques, increasing production time and material waste, which raises the overall price.

Q: Can I get volume discounts for bulk stainless steel well screen purchases?

A: Many manufacturers offer tiered pricing for large orders due to reduced per-unit production costs. Discount rates vary by supplier and order size.