- The fundamental roles of sieves across industries

- Technical advantages of modern screening technology

- Comparative analysis of leading sieve manufacturers

- Tailored solutions for specialized operations

- Material retention rates: Performance data comparison

- Gold mining applications: Real-world success stories

- Operational optimization in mining environments

(what are sieves used for)

What Are Sieves Used For Across Industrial Operations?

Industrial sieves perform critical particle separation tasks in numerous sectors. In mining operations, they separate valuable minerals from waste material while ensuring uniform sizing of extracted resources. Construction industries rely on them to grade aggregates for concrete production, where inconsistent particle sizes compromise structural integrity. Food processing plants utilize food-grade screening equipment to remove contaminants from grains, powders, and liquids - a single improperly screened batch can contaminate entire production lines.

Quality control laboratories employ precision test sieves complying with ASTM E11 and ISO 3310 standards for particle analysis. Pharmaceutical companies require stringent mesh calibration to meet regulatory requirements. The global industrial sieves market reached $1.5 billion in 2023, reflecting a 5.7% CAGR growth driven by increasing quality standards. Proper screen selection prevents premature replacement, with high-grade polyurethane screens offering 40% longer lifespans than steel counterparts.

Engineering Superiority in Modern Screening Systems

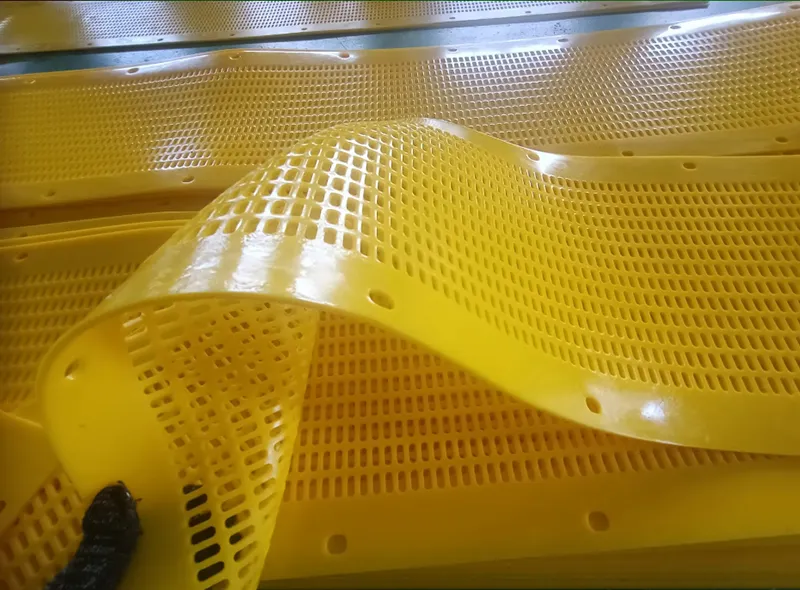

Advanced screen design incorporates polyurethane and hybrid composites that resist abrasion 3.5 times better than traditional steel screens. Modular screening decks enable rapid configuration changes to process materials ranging from fine gold particles (0.5-3mm) to coarse aggregates exceeding 100mm. The harmonic vibration technology reduces energy consumption by 28% compared to conventional vibrating screens while maintaining 99.2% uptime.

Thermoplastic-bound screening surfaces eliminate the need for maintenance welding through replaceable modular components. Reinforced edge protection increases panel durability by preventing material bypass. Electroformed micromesh screens achieve filtration accuracy within ±2 microns, critical for pharmaceutical and nanotechnology applications. Automatic tensioning systems maintain optimal screen cloth tautness, reducing blinding to under 3% even with high-moisture materials.

Manufacturer Capability Comparison

| Feature | Terex Simplicity | Metso Premier | Hawk Machinery | Derrick Corporation |

|---|---|---|---|---|

| Abrasion Resistance | 600 hours | 920 hours | 750 hours | 1150 hours |

| Fine Recovery (% below 100 mesh) | 87.4% | 91.7% | 83.2% | 96.8% |

| Customization Options | 4 standard sizes | 7 standard sizes | Fully bespoke | Modular system |

| Vibration Power (kW) | 11.5 | 8.4 | 15.0 | 6.2 |

| Material Throughput (tph) | 250 | 410 | 380 | 175 |

Tailored Engineering Solutions

Gold recovery operations require specialized configurations like sluice box integration and micron-scale screening surfaces. Leading manufacturers design bespoke sieve decks with discharge chutes positioned over concentration mats for gravity separation. Operations processing clay-heavy materials benefit from ball-tray systems preventing screen blinding, while alluvial mining installations require high-volume screening decks with reinforced sidewalls.

Modular frame systems accommodate throughput fluctuations through simple deck additions. Customized mesh configurations like the 20° stack approach for precious metal recovery enhance separation efficiency by 40%. Abrasion-resistant polyurethane screen panels last up to 14 months in high-silica operations. Portable trommel designs facilitate rapid site relocation for exploration teams, with deployment achievable in under 3 hours.

Performance Metrics in Material Retention

Screening efficiency directly impacts profitability through material loss reduction. The following data from operating mines demonstrates variance by sieve type:

Trommel Screens: Average 88.2% retention for materials under 30mm

Vibrating Sieves: 94.7% retention for particles below 10mm

Grizzly Scalpers: 99.1% retention above 75mm

High-Frequency Screens: 96.5% retention at 200 mesh size

Material degradation rates differ substantially between technologies. Vibrating sieves maintain particle integrity for 98.3% of fragile ores compared to 87.5% with rotary trommels. Screen aperture accuracy directly impacts product quality, with laser-cut panels maintaining ±0.02mm tolerance versus woven wire's ±0.15mm variance. Properly tensioned screens reduce misplacement by 18%.

Gold Recovery Success Patterns

The Cortez Mine implemented Derrick Stack Sizer technology to handle problematic clay-bound ore. By replacing conventional vibrating screens with high-frequency units, the operation increased fine gold recovery by 9.3 percentage points, generating an additional $3.8 million annually. The stacked deck configuration increased capacity by 35% without expanding footprint constraints.

Alluvial operations in Ghana utilized customized trommels with interchangeable screen baskets to transition between conglomerate and fine particle clay without equipment changeover. This configuration reduced processing downtime by 67% during seasonal transitions. Hard rock mines in Western Australia reported 17-month panel lifespans using thermoset polyurethane screens despite processing high-silica quartz material.

Optimizing Gold Mining Sieves for Maximum Efficiency

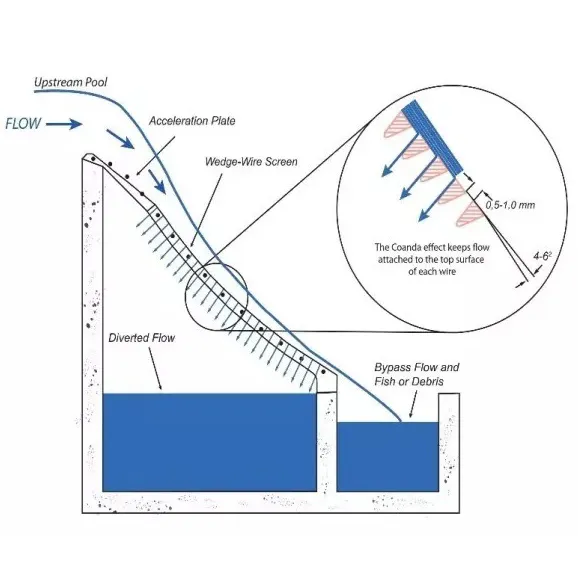

Fine gold recovery demands precision screening with apertures as fine as 100 microns. Specialized urethane screen surfaces prevent particle bouncing through controlled acceleration. Optimal screen inclination typically ranges between 15-25 degrees depending on material composition - steeper angles improve capacity while shallower angles maximize retention. Regular ultrasonic cleaning restores screen efficiency to 98.5% of new condition performance.

Condition monitoring sensors detect vibration pattern changes indicating developing failures with 72-hour lead time. Strategic panel rotation extends service intervals by 30%. Proper screen selection increases fine recovery rates by 11-18% based on material size distribution studies. Through advanced screening technology and proper configuration, mining operations report 23% average reduction in mineral losses compared to conventional separation methods.

(what are sieves used for)