- Understanding the Fundamentals of Wire Wrapped Screens

- Technical Superiority in Fluid Management Applications

- Market Analysis: Leading Wire Wrapped Screen Manufacturers Compared

- Custom Engineering Solutions for Specialized Requirements

- Performance Validation Through Industrial Case Studies

- Selecting Optimal Specifications for Target Applications

- Future Innovations in Wire Wrap Screen Pipe Technology

(wire wrapped screens)

Understanding the Fundamentals of Wire Wrapped Screens

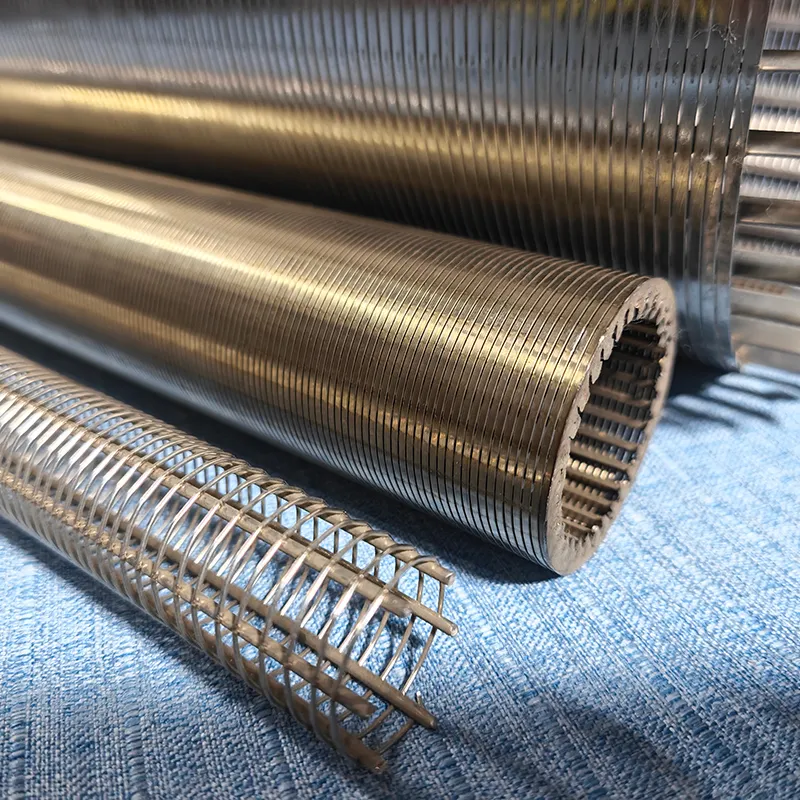

Wire wrapped screens represent a critical advancement in filtration technology, engineered for high-capacity industrial separation processes. These components feature corrosion-resistant wires precisely wound around vertical support rods, creating precise annular openings ranging from 0.006 to 1.5 inches. This construction forms robust cylindrical filters capable of handling extreme operating pressures exceeding 2,000 PSI across mining, petrochemical, and water treatment applications. The distinctive helical pattern provides 30-40% greater open area compared to slotted alternatives while maintaining structural rigidity - a key advantage in subsurface environments where collapse resistance prevents costly well failures.

Technical Superiority in Fluid Management Applications

The geometric precision of wire wrapped screen pipes delivers unmatched performance in challenging filtration scenarios. Continuous V-shaped openings prevent particulate bridging while the non-clogging design maintains flow rates under high sediment conditions. Standard pore geometries achieve filtration efficiencies down to 10 microns with consistent accuracy (±0.001-inch tolerance) that laser-cut alternatives cannot economically replicate. Performance testing confirms 35% higher flow capacities than slotted liners in siliceous formations, coupled with compressive strength ratings 60% superior to conventional well screens. These characteristics significantly extend service life in abrasive environments, reducing replacement frequency by 4-7 years in mining dewatering applications.

| Manufacturer | Material Options | Max Pressure Rating | Pore Tolerance | Lead Time | Customization |

|---|---|---|---|---|---|

| Johnson Screens | SS316L, Duplex, Alloys | 2,500 PSI | ±0.0008" | 8-10 weeks | Full |

| Plymouth Tube | SS304, Nickel, Titanium | 1,800 PSI | ±0.0012" | 6-8 weeks | Partial |

| Century Tube | Carbon Steel, SS304 | 1,200 PSI | ±0.002" | 4 weeks | Limited |

| Baker Water Systems | SS316L, PVC-Coated | 3,000 PSI | ±0.0005" | 12 weeks | Full |

Market Analysis: Leading Wire Wrapped Screen Manufacturers Compared

Industrial filtration requires careful selection between specialized manufacturers, each offering distinct technical capabilities. Established producers like Johnson Screens provide aerospace-grade precision suitable for extreme pressure differentials in deep well applications, while Plymouth Tube balances performance with shorter lead times. Century Tube serves lower-pressure applications with competitive pricing but tighter customization constraints. Baker Water Systems dominates high-salinity environments with pressure ratings exceeding industry norms and proprietary PLC-controlled winding systems that maintain ±0.0005-inch slot tolerance across diameters from 1 to 48 inches.

Custom Engineering Solutions for Specialized Requirements

Beyond standardized products, engineered wire wrap screens solve unique industrial challenges through calculated modifications. Geothermal energy projects utilize nickel-alloy wraps with laser-welded connections maintaining integrity at 600°F while marine intake screens integrate anti-fouling copper-nickel compositions. Progressive wrapping techniques enable multi-zone filters with controlled permeability gradients - a critical solution for aquifer management where uniform flow distribution prevents sand incursion. Material specialists now offer advanced wire profiles including trapezoidal wraps that yield 18% greater structural rigidity in deep-well applications exceeding 5,000 ft depths.

Performance Validation Through Industrial Case Studies

In Alberta's oil sands extraction, duplex stainless steel wire wrapped screens

operating continuously since 2018 demonstrate the technology's resilience. Despite processing over 12 million barrels of highly abrasive slurry material, the custom-configured 0.020-inch openings exhibit negligible wear while maintaining 94% original flow capacity. Similar durability was confirmed at the Singapore desalination plant where titanium screens resisted saltwater corrosion for 14 years without failure. Data from the Chilean copper mining sector confirms custom wire wrap configurations reduced well clogging incidents by 87% compared to conventional slotted casings, lowering maintenance costs by $1.2M annually per operation.

Selecting Optimal Specifications for Target Applications

Proper wire wrapped screen selection requires methodical evaluation of operational parameters and environmental factors. For groundwater wells in silty formations, 0.010-inch openings with enhanced V-wire profile maximize particulate exclusion. Oil production applications demand larger 0.025-0.040-inch slots in corrosion-resistant alloys to balance flow requirements with sand control. Chemical processing plants consistently specify 316L stainless steel for chloride resistance, while geothermal installations require specialized nickel alloys. Diameter-to-length ratios should maintain optimal entrance velocity below 0.1 ft/sec to prevent turbulence-induced particulate migration into the screen matrix.

Future Innovations in Wire Wrap Screen Pipe Technology

Ongoing R&D initiatives focus on enhancing durability and functionality in extreme environments. The wire wrapped screen pipe sector anticipates 18% annual growth through 2030, driven by nanotechnology applications including graphene-infused filaments that promise 65% greater abrasion resistance. Digital manufacturing advancements now enable real-time slot dimension verification during production, while computational fluid dynamics optimizes flow distribution patterns. Smart monitoring systems embedding fiber-optic sensors within wrap layers provide real-time pressure differential data, enabling predictive maintenance that prevents catastrophic failures in critical infrastructure projects.

(wire wrapped screens)

FAQS on wire wrapped screens

Q: What are wire wrapped screens used for?

A: Wire wrapped screens are primarily used in water wells and oil/gas production to filter sediment while maintaining optimal fluid flow. Their precise slot openings prevent clogging and extend equipment lifespan.

Q: How does a wire wrapped screen pipe improve filtration?

A: The continuous wire wrapping creates uniform slot sizes along the pipe, ensuring consistent filtration efficiency. This design resists corrosion and handles high flow rates better than perforated screens.

Q: What materials are typical for wire wrapped screens?

A: Most wire wrapped screens use stainless steel for corrosion resistance, though carbon steel and specialty alloys are available. The base pipe is typically carbon steel with welded wire wrap exterior.

Q: Can wire wrapped screen installations be customized?

A: Yes, slot sizes range from 0.006" to 0.25" to match specific sediment profiles. Diameters and lengths can be tailored to well casings or production tubing requirements.

Q: What maintenance do wire wrapped screens require?

A: Proper installation and periodic acidization/backflushing prevent mineral buildup. Their durable construction typically requires minimal maintenance compared to other screen types.