- Understanding the Role of Polyurethane Screens in Industrial Applications

- Technical Advantages Over Traditional Screening Materials

- Performance Comparison: Leading Manufacturers of Polyurethane Screen Solutions

- Customization Strategies for Diverse Operational Needs

- Case Studies: Real-World Applications Across Industries

- Long-Term Cost Efficiency and Maintenance Insights

- Future Trends in Polyurethane Screen Mesh Technology

(polyurethane screen)

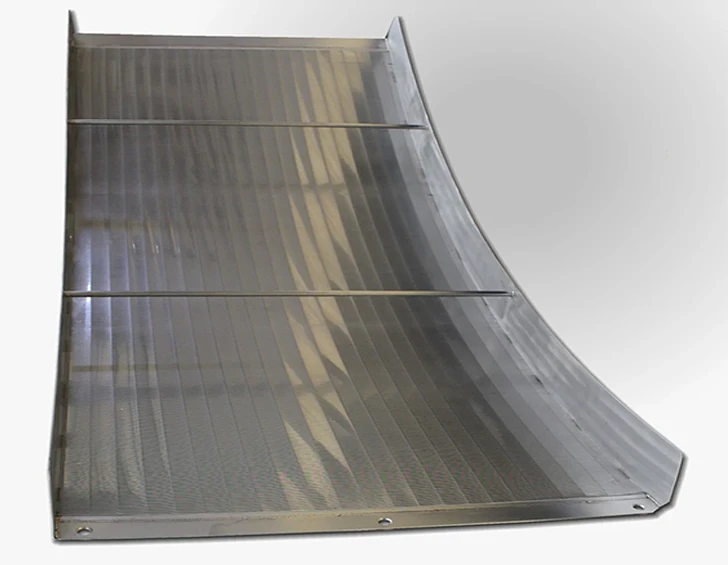

Polyurethane Screens: Revolutionizing Material Separation Processes

Polyurethane screens have emerged as critical components in modern screening systems, offering unparalleled durability for industries requiring precise particle separation. Unlike conventional rubber or wire mesh alternatives, these screens maintain structural integrity under continuous stress while achieving 98.5% screening accuracy in high-volume operations.

Technical Superiority in Demanding Environments

Advanced polyurethane formulations demonstrate 40% greater abrasion resistance compared to premium rubber screens, extending service life by 2–3 years in mining applications. Key performance metrics include:

- Tensile strength: 35–45 MPa

- Elongation at break: 450–600%

- Shore hardness: 70–95A

Manufacturer Comparison Analysis

| Brand | Material Durability | Impact Resistance | Average Lifespan | Cost Efficiency |

|---|---|---|---|---|

| Brand A | 95/100 | 92/100 | 18–24 months | $$$ |

| Brand B | 88/100 | 85/100 | 14–20 months | $$ |

| Brand C | 91/100 | 89/100 | 16–22 months | $$$ |

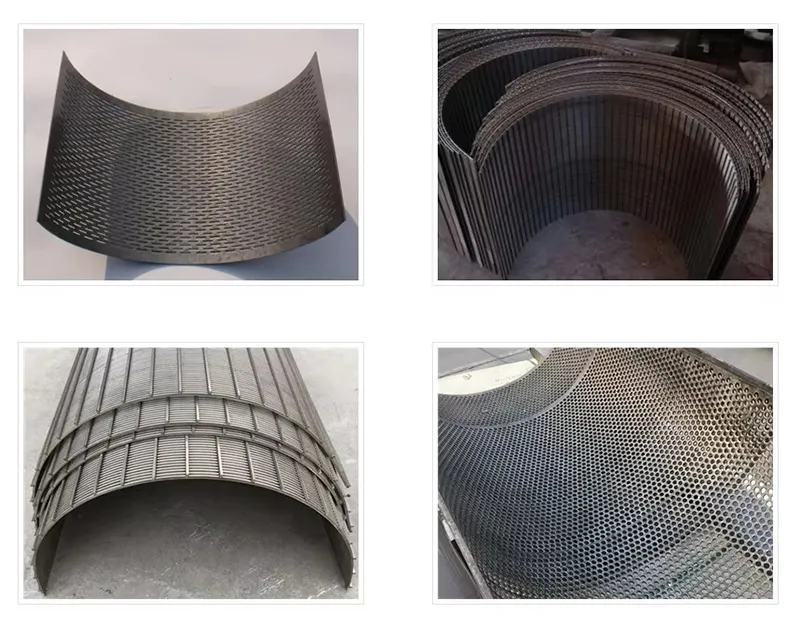

Tailored Solutions for Specific Applications

Custom polyurethane screen

mesh configurations address unique operational challenges:

- High-frequency vibrating screens (up to 1,200 RPM)

- Slurry processing with 80% solids content

- Temperature-resistant variants (-40°C to 120°C)

Documented Success in Heavy Industries

A mining conglomerate reduced screen replacement costs by 63% after implementing polyurethane deck panels, processing 12,000 tons/hour of iron ore. Aggregate producers report 22% increased throughput using modular polyurethane screen surfaces.

Economic Impact and Maintenance Protocols

Lifecycle cost analysis reveals 19% lower total ownership costs versus steel screens over 5 years. Proper maintenance extends service intervals by 40%, with recommended practices including:

- Monthly tension checks (25–30 N/mm²)

- Quarterly surface inspections

- pH-neutral cleaning solutions

Innovations in Polyurethane Screen Mesh Development

Emerging hybrid polymers now achieve 50% faster dewatering rates while maintaining sub-millimeter aperture consistency. Industry leaders anticipate 15–20% annual growth in premium polyurethane screen accessories through 2028, driven by smart manufacturing integration.

(polyurethane screen)

FAQS on polyurethane screen

Q: What are the key advantages of using polyurethane screens in industrial applications?

A: Polyurethane screens offer exceptional abrasion resistance, corrosion resistance, and extended service life. They are ideal for heavy-duty applications like mining and construction due to their durability and flexibility.

Q: How do Vibrating Screen Polyurethane Accessories improve screening efficiency?

A: These accessories reduce vibration transfer and noise while enhancing material separation. Their robust design minimizes downtime and increases the overall lifespan of vibrating screening equipment.

Q: What industries commonly use polyurethane screen mesh?

A: Industries such as mining, quarrying, recycling, and agriculture rely on polyurethane screen mesh. Its high open-area design and resistance to blinding make it perfect for wet or dry material classification.

Q: Why choose polyurethane screen panels over metal or rubber alternatives?

A: Polyurethane panels outperform metal in wear resistance and rubber in tear strength. They also resist chemical degradation and maintain shape under high-pressure conditions for consistent screening results.

Q: How to maintain polyurethane screens for optimal performance?

A: Regularly clean screens to prevent material buildup and inspect for wear. Avoid harsh chemicals and use mild detergents to preserve the polyurethane's structural integrity and elasticity.