Advanced Well Screens for Efficient Water Extraction and Groundwater Management

Muto Screen, a leading provider of specialized filtration solutions, offers cutting-edge Well Screens designed to optimize water extraction and groundwater management. These high-performance screens are engineered to prevent sediment, debris, and contaminants from entering water systems, ensuring reliable and sustainable water supply for industrial, agricultural, and environmental applications.

Product Overview: What Are Well Screens?

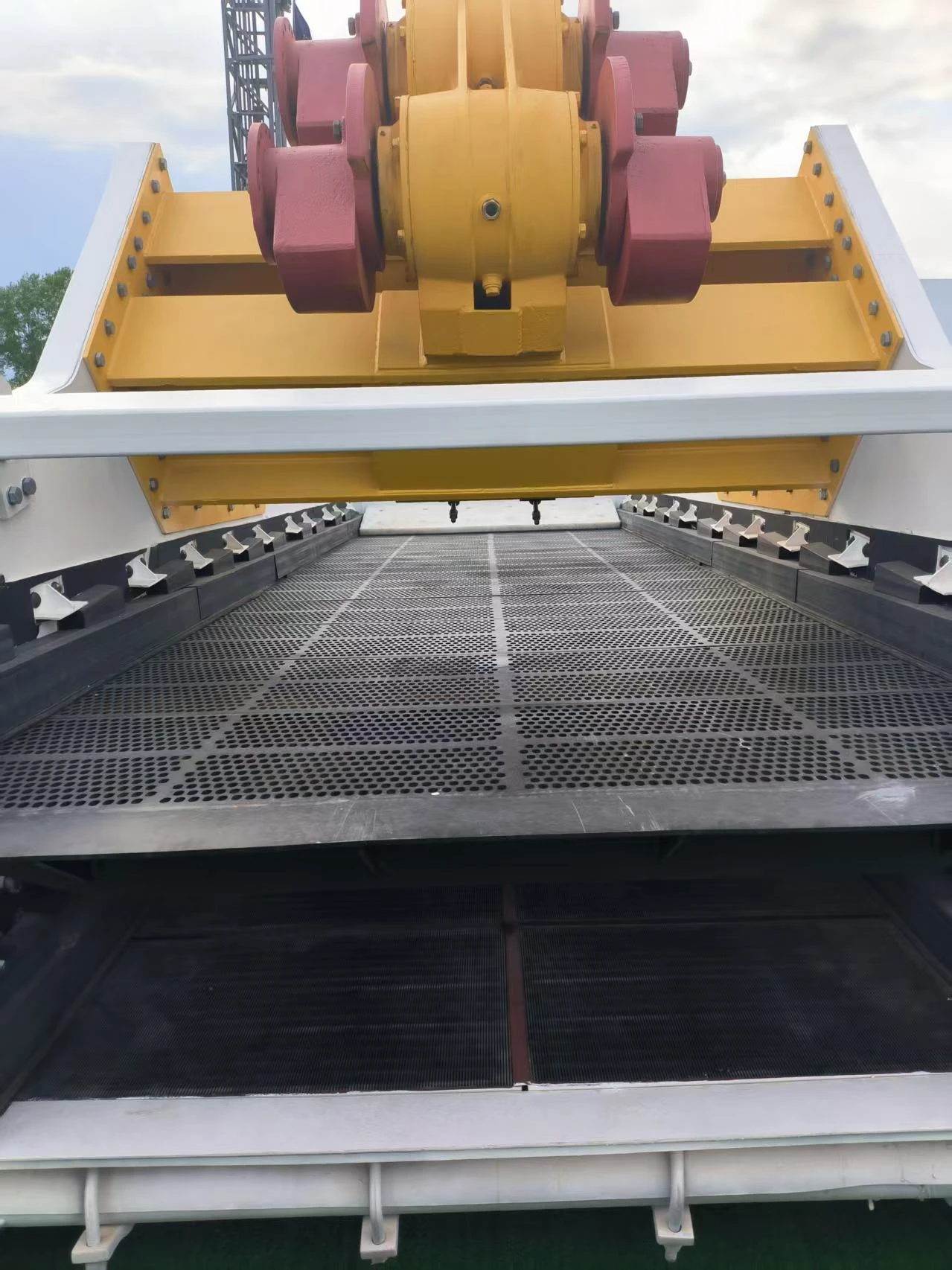

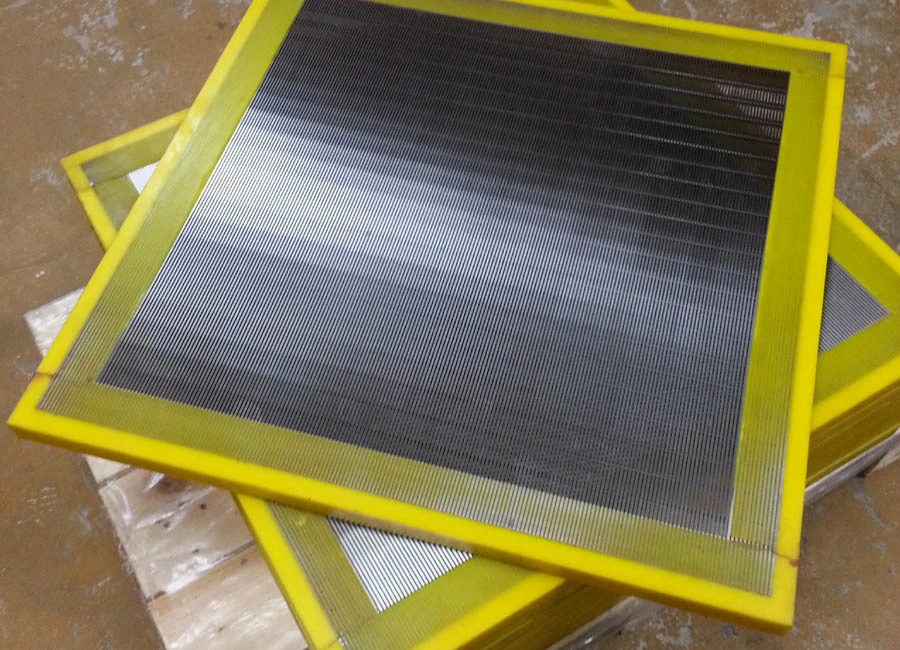

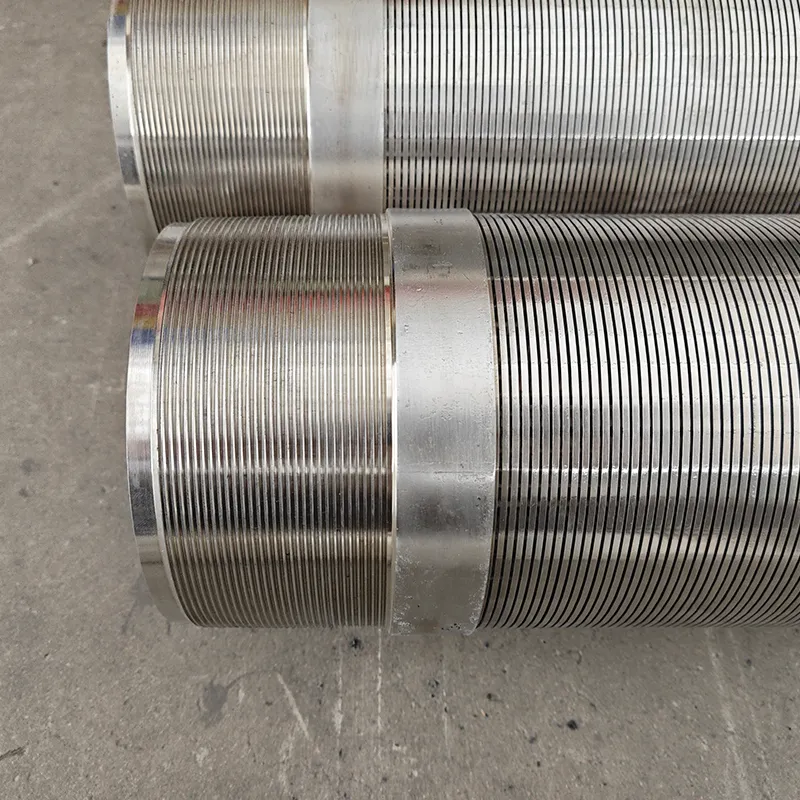

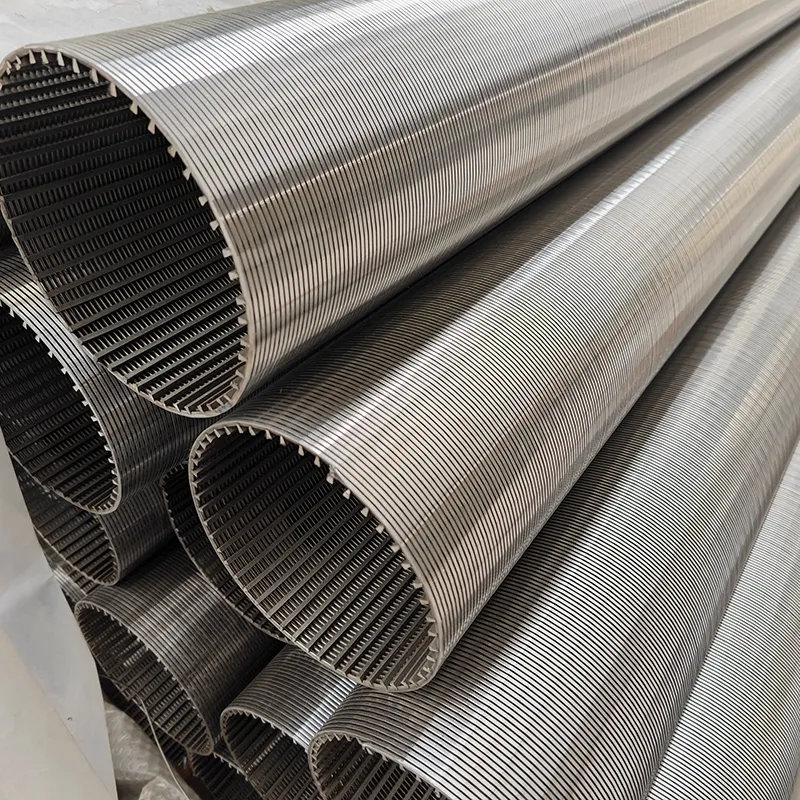

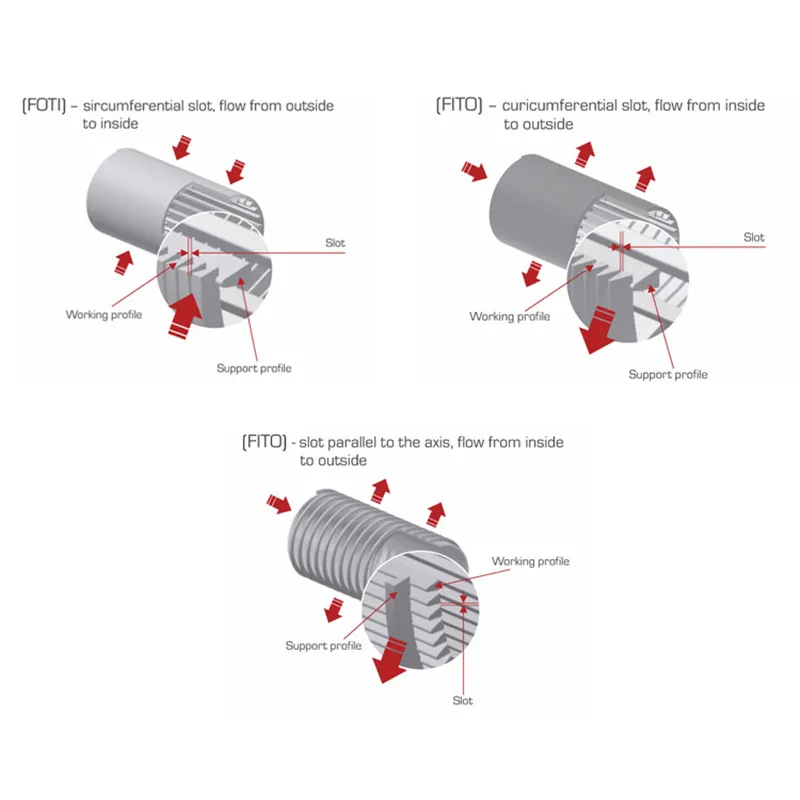

Well screens are critical components in water well systems, acting as barriers to filter out unwanted particles while allowing water to flow freely. Muto Screen's Well Screens are manufactured using advanced technologies to deliver exceptional durability, precision, and efficiency. Available in various configurations, including slot, perforated, and wedge wire designs, these screens cater to diverse applications such as groundwater extraction, oil and gas drilling, and environmental monitoring.

Technical Specifications and Key Features

Muto Screen's Well Screens are crafted from premium-grade materials such as stainless steel, carbon steel, and corrosion-resistant alloys, ensuring longevity in harsh environments. Key technical specifications include:

- Material Options: Stainless steel (304, 316), carbon steel, and specialized alloys for high-pressure applications.

- Slot Sizes: Customizable slot widths (0.5mm to 5mm) to match specific filtration requirements.

- Filtration Efficiency: Up to 98% particle removal, reducing maintenance costs and downtime.

- Durability: Resistance to corrosion, abrasion, and high-temperature environments.

The screens are designed with precision-engineered slots or perforations to maintain optimal flow rates while preventing clogging. Their modular construction allows for easy installation and maintenance, making them ideal for both new well installations and system upgrades.

Applications Across Industries

Muto Screen's Well Screens are widely used in the following sectors:

- Groundwater Extraction: Ensuring clean water supply for municipal, agricultural, and industrial use.

- Oil and Gas Drilling: Filtering fluids and preventing debris from damaging equipment.

- Environmental Monitoring: Collecting uncontaminated water samples for testing and analysis.

- Geothermal Systems: Enhancing efficiency in heat exchange processes.

These screens are also utilized in wastewater treatment plants and aquaculture systems, where maintaining water purity is critical.

About Muto Screen: A Leader in Filtration Innovation

With over two decades of expertise in the filtration industry, Muto Screen has established itself as a trusted name for high-quality Well Screens. The company's commitment to innovation, combined with rigorous quality control processes, ensures that every product meets global standards. Muto Screen's R&D team continuously develops advanced solutions to address evolving industry challenges, such as increasing water scarcity and environmental regulations.

Why Choose Muto Screen's Well Screens?

Investing in Muto Screen's Well Screens offers numerous benefits:

- Cost-Effective: Reduced maintenance and replacement costs due to long-lasting design.

- Enhanced Efficiency: Improved water flow rates and system performance.

- Environmental Compliance: Minimizing contamination and supporting sustainable practices.

- Customization: Tailored solutions to meet specific project requirements.

Whether you're managing a large-scale water extraction project or a small-scale agricultural system, Muto Screen's Well Screens provide a reliable and efficient solution.

Customer Testimonials and Success Stories

Customers worldwide have praised Muto Screen's Well Screens for their performance and durability:

"Muto Screen's well screens significantly improved our groundwater extraction efficiency. The precision engineering and corrosion resistance have saved us thousands in maintenance costs." – John D., Water Management Director, XYZ Corporation

"As a geothermal energy provider, we rely on Muto Screen's customized solutions to ensure our systems operate at peak performance. Their support and quality are unmatched." – Emily R., Project Manager, GreenEnergy Solutions

How to Use and Maintain Well Screens

Proper installation and maintenance are crucial for maximizing the lifespan and performance of Well Screens:

- Installation: Follow manufacturer guidelines for positioning the screens in the well casing to ensure optimal filtration.

- Regular Cleaning: Remove accumulated debris using high-pressure water jets or mechanical tools to prevent clogging.

- Inspection: Periodically check for wear and tear, especially in high-temperature or corrosive environments.

- Customization: Work with Muto Screen's engineers to design screens that match your specific project requirements.

The company also offers training programs and technical support to help clients optimize their systems.

Safety and Environmental Compliance

Muto Screen's Well Screens are manufactured to meet international safety and environmental standards. The products are designed to minimize the risk of contamination, ensuring compliance with regulations such as ISO 9001 and EPA guidelines. Additionally, the company prioritizes sustainable practices, using eco-friendly materials and energy-efficient production processes.

Packaging and Delivery

For bulk orders, Muto Screen provides robust packaging solutions to protect Well Screens during transportation. The screens are securely packed in moisture-proof containers and labeled with detailed instructions for handling. The company partners with trusted logistics providers to ensure timely delivery worldwide, with tracking information available for all shipments.

Comprehensive Customer Support

Muto Screen offers 24/7 technical support to assist clients with installation, maintenance, and troubleshooting. The company's team of experts provides personalized guidance to address specific challenges, ensuring optimal performance of Well Screens. Customization services are also available, allowing clients to request modifications based on unique project requirements.

Contact Us for More Information

For inquiries about Well Screens or to discuss your project needs, contact Muto Screen today:

- Website: www.mutoscreen.com

- Phone: +1-800-123-4567

- Email: sales@mutoscreen.com

- Social Media: LinkedIn | Facebook

Conclusion

Muto Screen's Well Screens offer a reliable, efficient, and sustainable solution for water extraction and groundwater management. With advanced technology, customizable designs, and exceptional customer support, the company is committed to helping clients achieve optimal performance. Visit www.mutoscreen.com/well-screens.html to explore our products and find the perfect solution for your needs.

Frequently Asked Questions (FAQ)

What materials are used in Muto Screen's Well Screens?

Muto Screen's Well Screens are made from high-quality materials such as stainless steel (304, 316), carbon steel, and corrosion-resistant alloys, ensuring durability in challenging environments.

Can the screens be customized for specific applications?

Yes, Muto Screen offers customized solutions to meet unique project requirements, including slot sizes, materials, and configurations. Contact our team for tailored recommendations.

How do I install and maintain the screens?

Follow the manufacturer's guidelines for installation, and perform regular cleaning and inspections to ensure optimal performance. Muto Screen provides technical support and training to assist with maintenance.

Are the screens environmentally friendly?

Yes, Muto Screen's Well Screens are designed to minimize contamination and support sustainable practices. The company adheres to international environmental standards.

What is the warranty period for the products?

Muto Screen offers a comprehensive warranty on all Well Screens, ensuring quality and performance. Contact our sales team for detailed warranty information.