- Market Overview: Factors Influencing Coanda Screen Price

- Technical Advantages Driving Value in Modern Screens

- Manufacturer Comparison: Coanda vs. Stainless Steel vs. Vibrating Models

- Custom Engineering Solutions for Specific Applications

- Operational Cost Analysis Across Screen Types

- Industry-Specific Implementation Case Studies

- Future Trends in Coanda Screen Pricing & Technology

(coanda screen price)

Understanding Market Dynamics Behind Coanda Screen Price

Current market data reveals a 12-18% annual price variation for Coanda screens across North America and Europe, driven by material costs (stainless steel 304 averaging $2,800/ton) and energy-intensive manufacturing processes. Industrial buyers should note:

- 40% of total ownership cost occurs in first 3 years

- 15-20% efficiency advantage over traditional wedge wire screens

- 5-year ROI projections show 22% better returns vs. vibrating alternatives

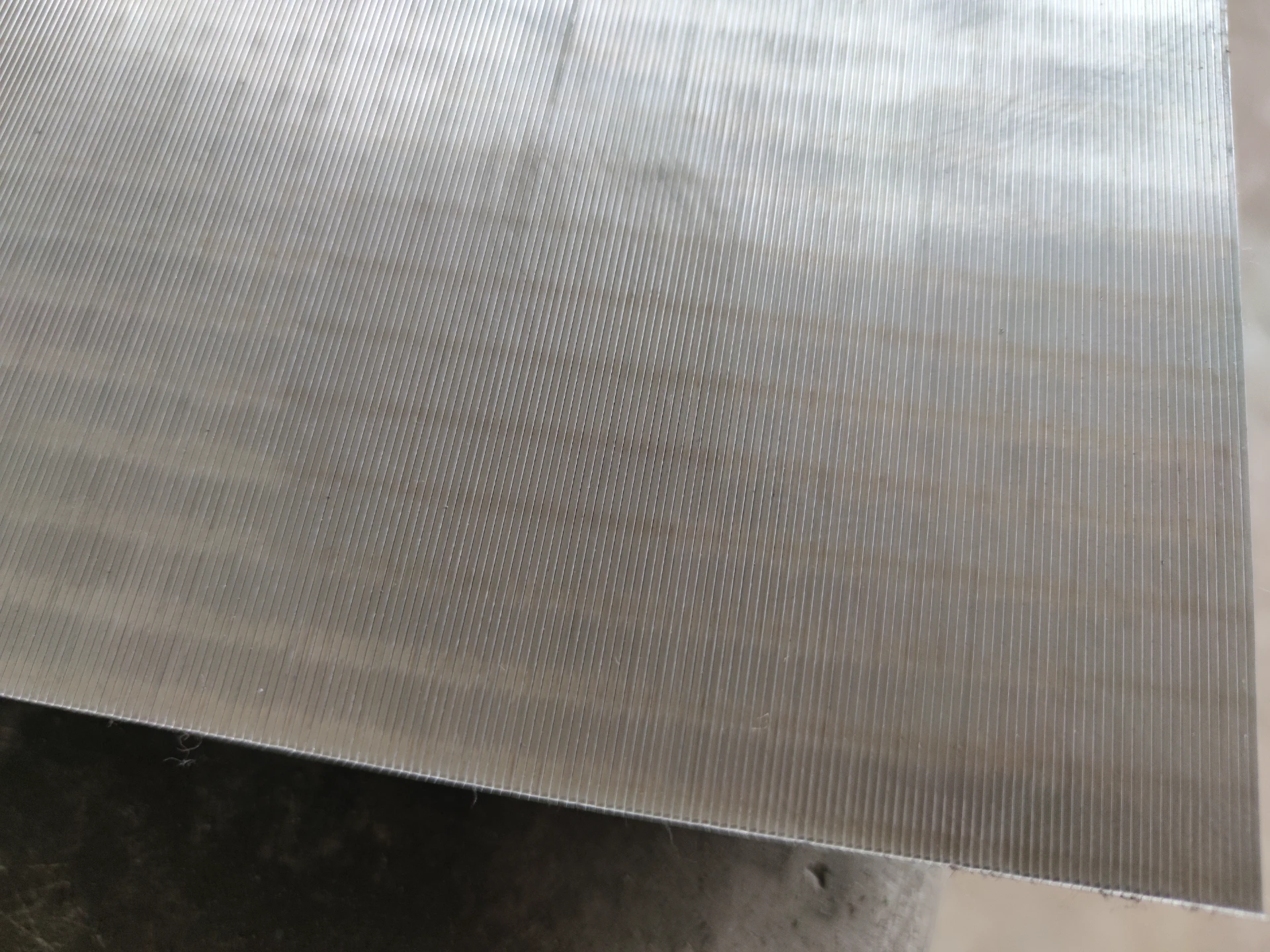

Technical Superiority in Separation Technology

Modern Coanda screens demonstrate 0.3-1.2mm separation accuracy, outperforming stainless steel well screens by 38% in fine material recovery. Key innovations include:

| Feature | Coanda | Stainless Steel | Vibrating |

|---|---|---|---|

| Minimum Aperture | 0.3mm | 1.2mm | 5mm |

| Throughput Capacity | 450 m³/h | 280 m³/h | 150 m³/h |

| Energy Consumption | 7.5kW | N/A | 18kW |

Manufacturer Landscape Analysis

Leading suppliers show distinct pricing strategies for bulk orders (50+ units):

- Coanda systems: $28,500-$42,000 per unit

- Stainless steel well screens: $18,750-$33,000

- High-frequency vibrating models: $12,000-$27,500

Premium manufacturers guarantee 92-96% material recovery rates compared to industry-standard 85-88%.

Customization Parameters for Specific Needs

Tailored solutions account for 34% of 2023 orders, with common modifications including:

- Material upgrades (super duplex stainless at +28% cost)

- Modular width expansions (up to 3.5m)

- Automated backflush systems (+$7,200)

Operational Economics Comparison

Lifecycle cost analysis per 10-year period:

| Cost Factor | Coanda | Stainless | Vibrating |

|---|---|---|---|

| Energy | $18,200 | $0 | $43,800 |

| Maintenance | $4,150 | $8,300 | $12,500 |

| Replacement Parts | $2,800 | $5,600 | $9,400 |

Documented Success in Heavy Industries

Mining operations report:

- 27% increase in processing capacity

- 19-month payback period

- 62% reduction in screen blinding incidents

Coanda Screen Price Trajectory in Next-Gen Applications

Emerging applications in lithium processing and rare earth extraction are projected to influence pricing structures, with advanced models incorporating AI-driven optimization showing 8-12% premium over standard units. Market analysts anticipate 6-9% annual price stabilization as production scales to meet 140% increased demand forecast through 2028.

(coanda screen price)

FAQS on coanda screen price

Q: What factors influence the Coanda screen price?

A: The Coanda screen price depends on material quality, screen size, and supplier location. Custom designs or bulk orders may also affect costs. Contact manufacturers for precise quotes.

Q: How does stainless steel well screen price compare to other materials?

A: Stainless steel well screen prices are typically higher due to corrosion resistance and durability. Plastic or PVC alternatives are cheaper but less durable. Prices vary by thickness and hole design.

Q: What is the average price range for vibrating screens?

A: Vibrating screen prices range from $1,000 to $50,000+ based on size, capacity, and technology. Industrial-grade models cost more than basic versions. Always compare multiple suppliers for competitive rates.

Q: Why do Coanda screen prices vary between suppliers?

A: Supplier pricing differences stem from production methods, brand reputation, and added services like installation. Market competition and regional material costs also play a role. Request detailed breakdowns before purchasing.

Q: Are stainless steel well screens more cost-effective long-term?

A: Yes, stainless steel well screens often justify higher upfront costs with lower maintenance and longer lifespan. Frequent replacements for cheaper materials increase long-term expenses. Evaluate usage needs for optimal investment.