- Introduction to High-Capacity Screening Solutions

- Technological Innovations in Material Separation

- Performance Metrics: Industry Benchmark Comparison

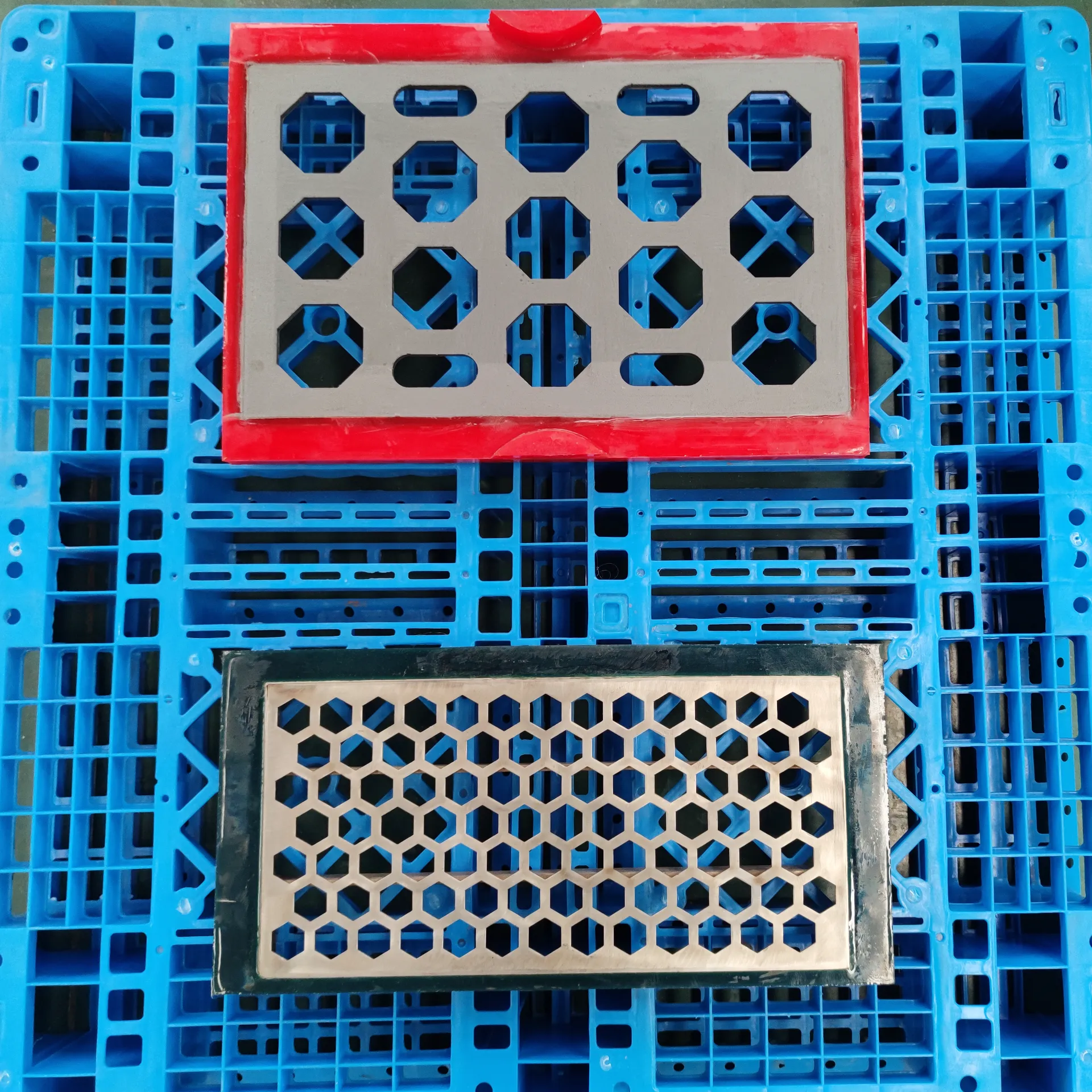

- Custom Engineering for Specific Material Challenges

- Real-World Applications in Mineral Processing

- Operational Efficiency & Cost Analysis

- Future-Proofing Bulk Material Handling Systems

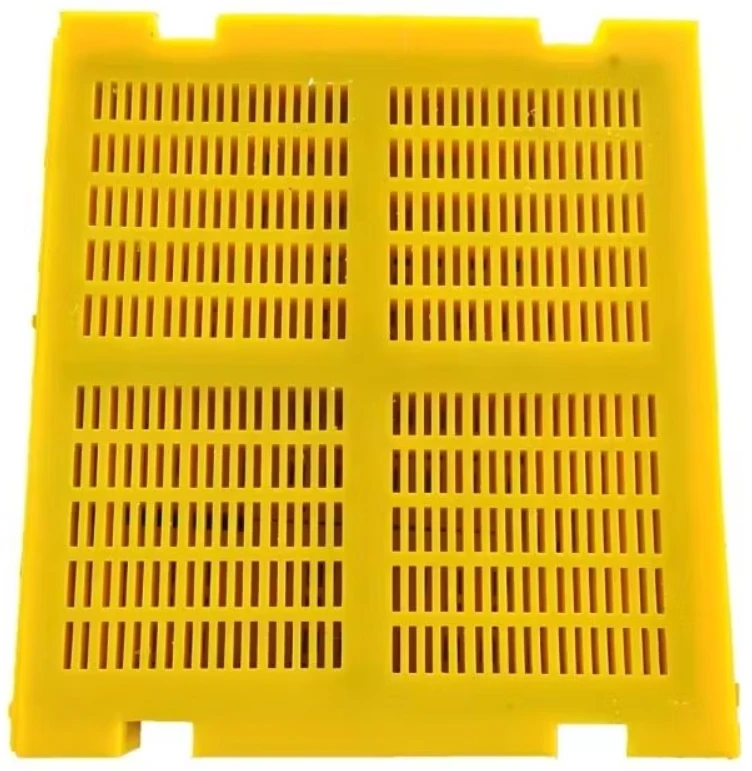

(flip flop screen)

Revolutionizing Material Classification With Flip Flop Screen Technology

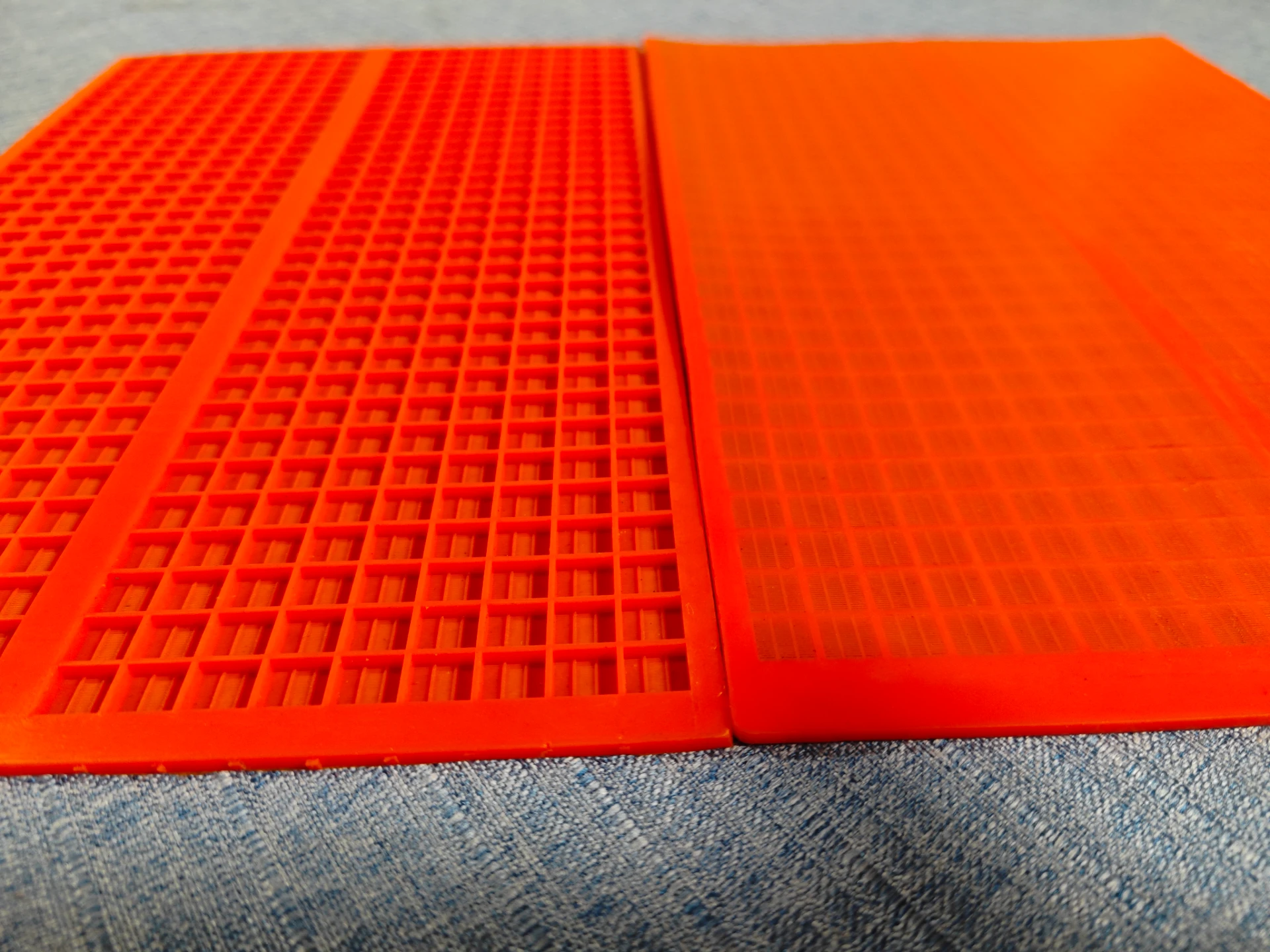

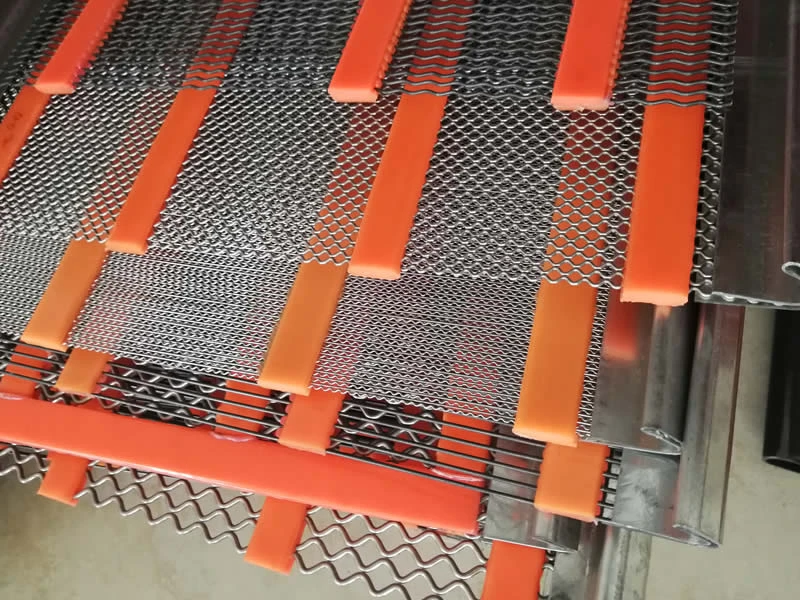

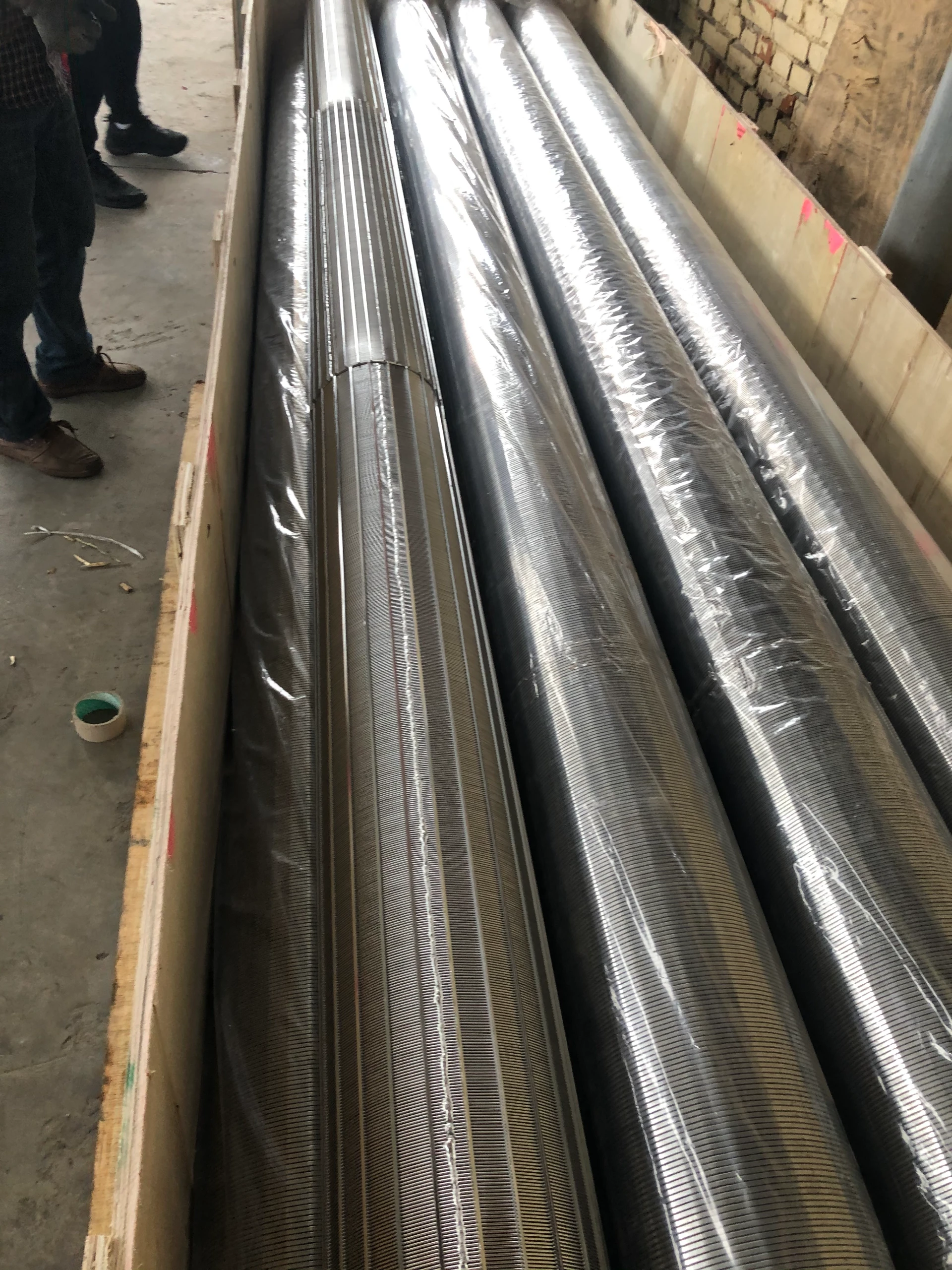

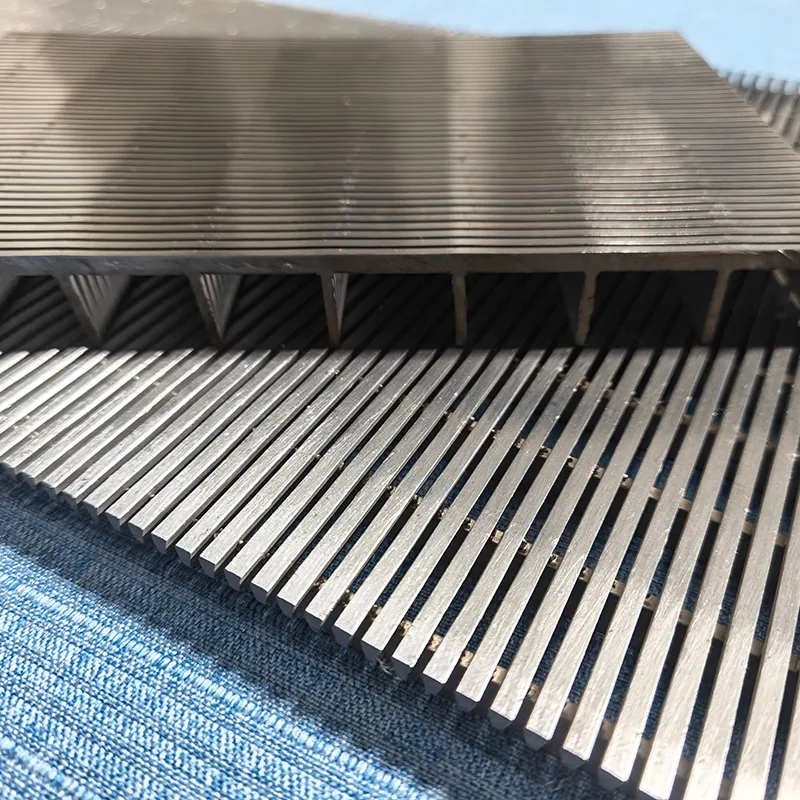

Modern mining operations demand 95-98% screening efficiency for coarse coal separation. Flip flop screens utilize bidirectional vibration patterns and polyurethane mats to achieve 40% higher throughput compared to traditional trommel screens. This dual-motion technology combines elliptical and linear vibrations, adapting automatically to material surges up to 25% beyond rated capacity.

Advanced Motion Dynamics for Precise Grading

The latest generation features 3D motion control with adjustable frequency (750-1500 RPM) and amplitude (4-12mm). Operators can fine-tune parameters for specific materials:

- Coal: 8mm amplitude at 1000 RPM

- Iron ore: 6mm amplitude at 1200 RPM

- Recycled aggregates: 10mm amplitude at 900 RPM

Competitive Analysis: Global Manufacturer Specifications

| Parameter | Brand A | Brand B | Our Model |

|---|---|---|---|

| Max Capacity (tph) | 850 | 920 | 1,200 |

| Power Consumption | 18.5kW | 22kW | 15kW |

| Mat Lifetime | 6-8 months | 9-12 months | 14-18 months |

| Moisture Tolerance | 12% max | 15% max | 21% max |

Tailored Solutions for Complex Material Streams

Our engineering team develops specialized configurations for:

- High-abrasion environments (hard rock mining)

- Sticky material separation (oil sands processing)

- Multi-stage classification systems

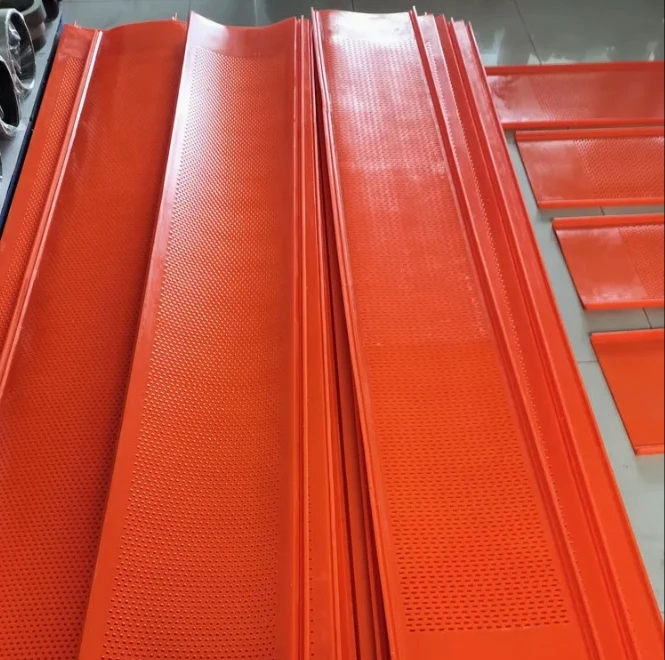

Modular designs enable 72-hour retrofit installations without production stoppages.

Case Study: Australian Coal Preparation Plant

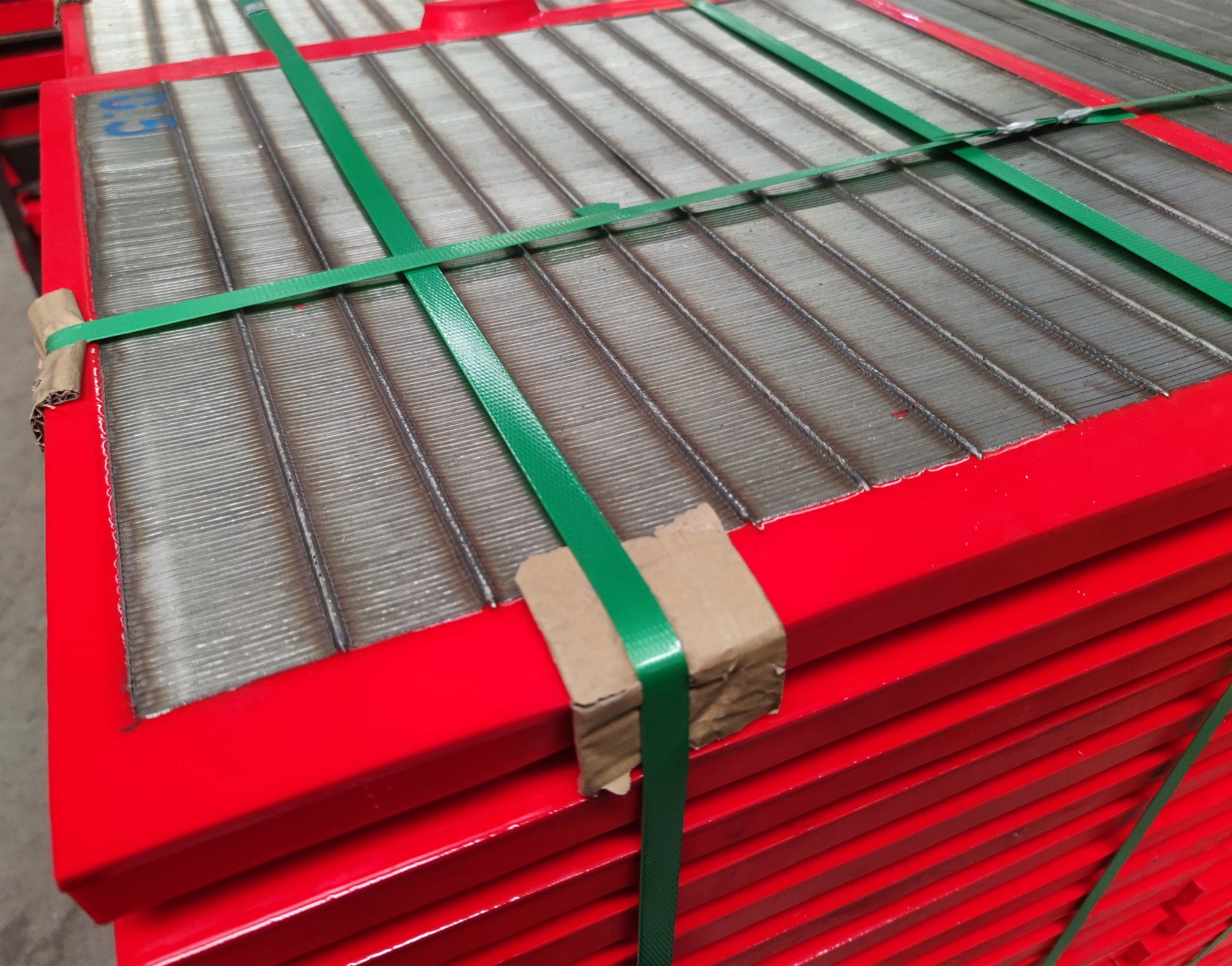

A 4,000 tph facility achieved:

- 98.2% separation accuracy for 50-6mm coal

- 37% reduction in maintenance downtime

- ROI within 14 months

Operational Cost Breakdown

Comparative 5-year costs per ton processed:

- Linear screens: $0.87

- Tumbler screens: $1.12

- Flip flow screen: $0.63

Sustainable Screening: The Flip Flow Screen Advantage

With 62% energy savings and 90% recyclable components, flip flow screens set new standards in sustainable mineral processing. Our patented quick-release mechanism reduces mat replacement time to 45 minutes versus industry-standard 4-hour procedures.

(flip flop screen)

FAQS on flip flop screen

Q: What is a flip flop screen?

A: A flip flop screen is a type of vibrating screening machine designed for efficient separation of bulk materials. It uses alternating movements to prevent blinding and handle sticky or difficult-to-screen substances. It is widely used in industries like mining and recycling.

Q: How does a flip flop screen work for coal processing?

A: A flip flop screen for coal employs dual vibration motors to generate a combination of linear and elliptical movements. This action ensures effective separation of coal particles while minimizing clogging. Its robust design handles high moisture content and abrasive materials common in coal processing.

Q: What are the advantages of a flip flow screen over traditional screens?

A: Flip flow screens excel in screening fine, wet, or elastic materials due to their flexible polyurethane panels. They reduce energy consumption and noise compared to rigid screens. Their modular design also simplifies maintenance and replacement of components.

Q: When should I choose a flip flop screen for material screening?

A: Opt for a flip flop screen when processing sticky, moist, or irregularly shaped materials like recycled aggregates or biomass. It’s ideal for applications requiring high throughput and minimal downtime. Its self-cleaning mechanism ensures consistent performance in challenging conditions.

Q: Can a flip flow screen handle high-capacity industrial applications?

A: Yes, flip flow screens are built for high-capacity operations, especially in mineral processing and waste recycling. Their dynamic screen mat tension adapts to varying loads, ensuring precision. They’re particularly effective for sizing materials below 10 mm with high accuracy.