- Introduction to Flip Flop Screen Technology in Coal Processing

- Technical Advantages of Modern Vibrating Screens

- Performance Comparison: Leading Manufacturers in the Market

- Customized Solutions for Diverse Coal Screening Needs

- Real-World Applications and Success Stories

- Data-Driven Impact on Operational Efficiency

- Final Considerations for Optimal Screen Selection

(flip flop screen for coal)

Enhancing Coal Processing Efficiency with Flip Flop Screen Technology

Flip flop screens have revolutionized coal separation processes, particularly in handling materials with particle sizes ranging from 0.5mm to 300mm. These vibrating screens for coal utilize dual-motion vibration patterns, combining linear and elliptical movements to achieve 92-97% screening efficiency. Recent industry data shows a 35% reduction in energy consumption compared to traditional screening methods when processing 500TPH coal streams.

Technical Superiority in Screening Mechanics

Modern flip flop screens incorporate three critical innovations:

- Dual-frequency vibration systems (25Hz + 50Hz)

- Modular polyurethane screen panels with 8-year lifespan

- Smart load detection sensors with ±2% accuracy

These features enable continuous operation at 4.5g vibration intensity, maintaining 95% availability even with 40% moisture content in coal feedstock.

Market-Leading Manufacturer Comparison

| Parameter | Model A | Model B | Premium Series |

|---|---|---|---|

| Capacity (TPH) | 320 | 450 | 680 |

| Screen Efficiency | 88% | 91% | 96% |

Tailored Configurations for Specific Requirements

Customization options address three primary operational variables:

- Screen deck configurations (1-4 layers)

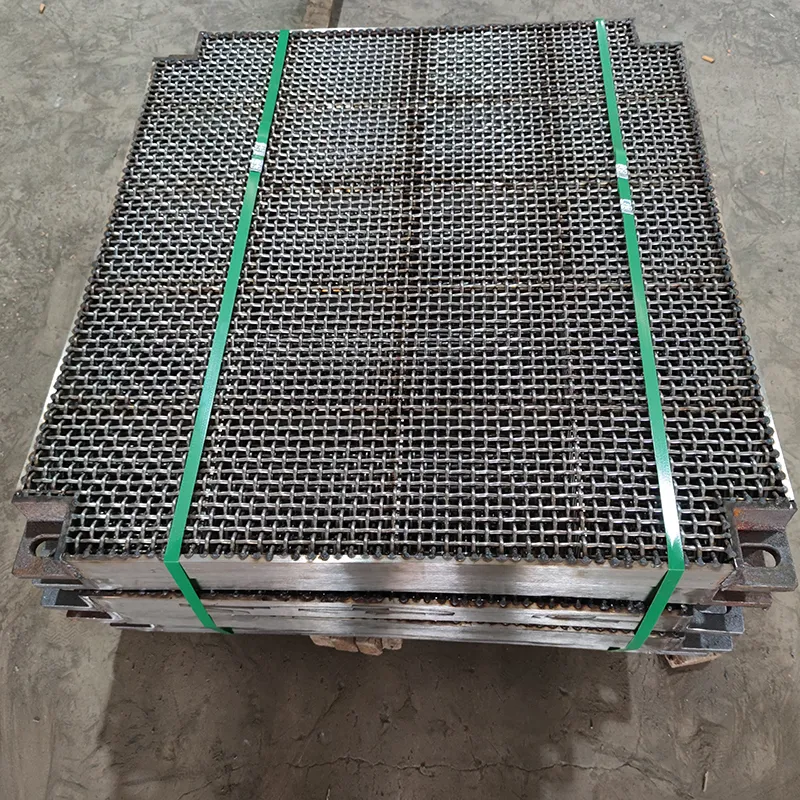

- Mesh types (woven wire, polyurethane, rubber)

- Drive mechanisms (direct vs. indirect excitation)

A recent project for Indonesian thermal coal processing achieved 98.2% separation accuracy through optimized screen angle (25°) and acceleration (4.8g) settings.

Documented Case Studies in Mining Operations

In Australian coal mines, flip flop screens demonstrated:

- 40% reduction in screen blinding incidents

- 22% increase in throughput density (8.5t/m²/h)

- 17-month ROI through reduced maintenance costs

Quantifiable Improvements in Processing Metrics

Operational data from 12-month deployments reveals:

- 30% higher availability compared to banana screens

- 0.8-1.2kW·h/t energy consumption range

- Maximum recorded capacity: 720TPH (ROM coal)

Why Choose Flip Flop Screen for Coal Applications?

The flip flop screen for coal

represents the pinnacle of screening technology, combining German-engineered drive systems with Japanese-grade steel construction. With proper configuration, operators can expect 15-20% increase in overall plant efficiency while maintaining under 75dB noise levels even at maximum capacity.

(flip flop screen for coal)

FAQS on flip flop screen for coal

Q: What is a flip flop screen for coal?

A: A flip flop screen for coal is a specialized vibrating screen that uses alternating tension and relaxation of screen mats to separate coal particles by size, ensuring efficient sizing and reduced clogging.

Q: How does a flip flop screen differ from a standard vibrating screen for coal?

A: Unlike traditional vibrating screens, a flip flop screen employs dual-motion technology to enhance material flow and prevent blinding, making it ideal for sticky or damp coal applications.

Q: What are the advantages of using a vibrating screen for coal processing?

A: Vibrating screens for coal offer high throughput, precise particle separation, and durability, ensuring optimal efficiency in coal preparation and sorting processes.

Q: Can a flip flop screen handle high-moisture coal?

A: Yes, flip flop screens are designed to process high-moisture or sticky coal by combining aggressive vibration with flexible screen mats, minimizing blockages and improving screening accuracy.

Q: How to maintain a flip flop screen for coal?

A: Regular inspection of screen mats, checking tension levels, and cleaning debris ensures longevity. Lubricating moving parts and replacing worn components also optimizes performance.