- Understanding the Critical Role of Mining Screens in Modern Operations

- Data-Driven Impact: How Mining Screens Optimize Efficiency

- Technical Superiority of Advanced Vibrating Screen Designs

- Manufacturer Comparison: Performance Metrics and Reliability

- Customized Solutions for Diverse Mining Applications

- Real-World Success Stories Across Industries

- Future-Proofing Operations with Next-Gen Mining Screens

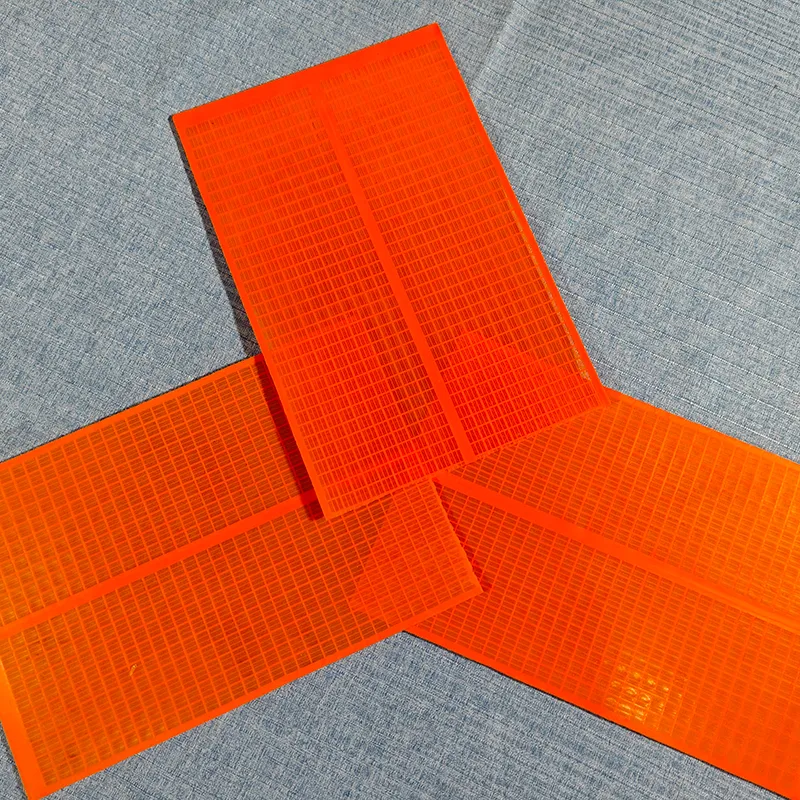

(mining screens)

Understanding the Critical Role of Mining Screens in Modern Operations

Mining screens, particularly mining vibrating screens, serve as the backbone of material separation processes in extractive industries. These systems efficiently segregate raw materials by particle size, ensuring downstream equipment receives optimized feedstock. Modern operations rely on robust screening solutions to handle abrasive ores, high-capacity throughput, and extreme environmental conditions. The shift toward automated, energy-efficient designs has elevated vibrating screens mining from auxiliary components to strategic productivity drivers.

Data-Driven Impact: How Mining Screens Optimize Efficiency

Recent industry studies reveal that advanced screening systems reduce processing downtime by 18-23% while increasing material recovery rates by 12-15%. Key performance indicators include:

- 30% higher throughput compared to traditional mesh screens

- 20% reduction in maintenance costs through modular component designs

- 15% energy savings via precision vibration control systems

Technical Superiority of Advanced Vibrating Screen Designs

Leading manufacturers now integrate three breakthrough technologies into vibrating screens mining applications:

- Multi-Frequency Resonance: Adapts to varying material densities in real-time

- Polyurethane-Medium Hybrid Decks: Combines wear resistance with precise screening accuracy

- Predictive Maintenance Sensors: Monitors bearing temperature and vibration patterns

Manufacturer Comparison: Performance Metrics and Reliability

| Manufacturer | Screening Capacity (t/h) | Durability (Operating Hours) | Energy Consumption | Price Range |

|---|---|---|---|---|

| HeavyDuty Screens Co. | 800-1,200 | 18,000 | 22 kW | $$$ |

| VibroTech Solutions | 1,500-2,000 | 24,000 | 18 kW | $$$$ |

| EcoScreen Dynamics | 500-900 | 15,000 | 15 kW | $$ |

Customized Solutions for Diverse Mining Applications

Tailored configurations address specific operational challenges:

- High-Moisture Material: Heated screen decks with anti-clogging mechanisms

- Fine Particle Separation: Micro-screening layers below 0.5mm aperture

- Remote Operations: IoT-enabled vibration adjustment and fault diagnostics

Real-World Success Stories Across Industries

A copper mine in Chile achieved 32% higher throughput after upgrading to multi-layer mining vibrating screens, while a Canadian oil sands operation reduced screen replacement frequency from quarterly to biannually through customized wear-resistant decks.

Future-Proofing Operations with Next-Gen Mining Screens

As mineral complexity increases and sustainability mandates tighten, mining screens

evolve beyond mechanical filters into intelligent process optimization nodes. Emerging technologies like AI-driven particle distribution analysis and self-cleaning screen surfaces position these systems as critical investments for long-term operational viability.

(mining screens)

FAQS on mining screens

Q: What are mining screens used for in the mining industry?

A: Mining screens separate and classify materials by size, ensuring efficient processing of ores and minerals. They improve productivity and reduce downtime in mining operations.

Q: How do mining vibrating screens work?

A: Mining vibrating screens use vibrations to sift and sort materials through mesh layers. This motion prevents clogging and ensures consistent particle sizing for downstream processes.

Q: What factors determine the choice of vibrating screens in mining?

A: Key factors include material type, particle size, capacity requirements, and environmental conditions. Screen design and vibration intensity are tailored to specific operational needs.

Q: How to maintain mining vibrating screens for optimal performance?

A: Regular inspection of mesh integrity, lubrication of moving parts, and cleaning debris ensures longevity. Monitoring vibration patterns helps detect wear early.

Q: What advantages do vibrating screens offer over static screens in mining?

A: Vibrating screens provide faster material handling, higher efficiency, and reduced blockages. Their dynamic operation adapts better to varying loads and coarse materials.