- Introduction to Conveyor Maintenance Challenges

- Technical Advancements in Scraping Systems

- Performance Comparison: Leading Manufacturers

- Custom Engineering for Specific Industries

- Case Study: Mining Sector Efficiency Gains

- Cost-Benefit Analysis of Secondary Cleaners

- Future Trends in Scraper Belt Cleaner Technology

(scraper belt cleaner)

Optimizing Operations with Scraper Belt Cleaner Solutions

Conveyor belt systems experience 23% productivity loss annually due to material carryback, according to Bulk Material Handling Journal (2023). Scraper belt cleaner technology addresses this by reducing residue accumulation by 89-94% in primary and secondary cleaning positions. These systems prevent:

- Belt misalignment (27% of conveyor downtime)

- Roller damage from abrasive materials

- Energy waste from increased friction

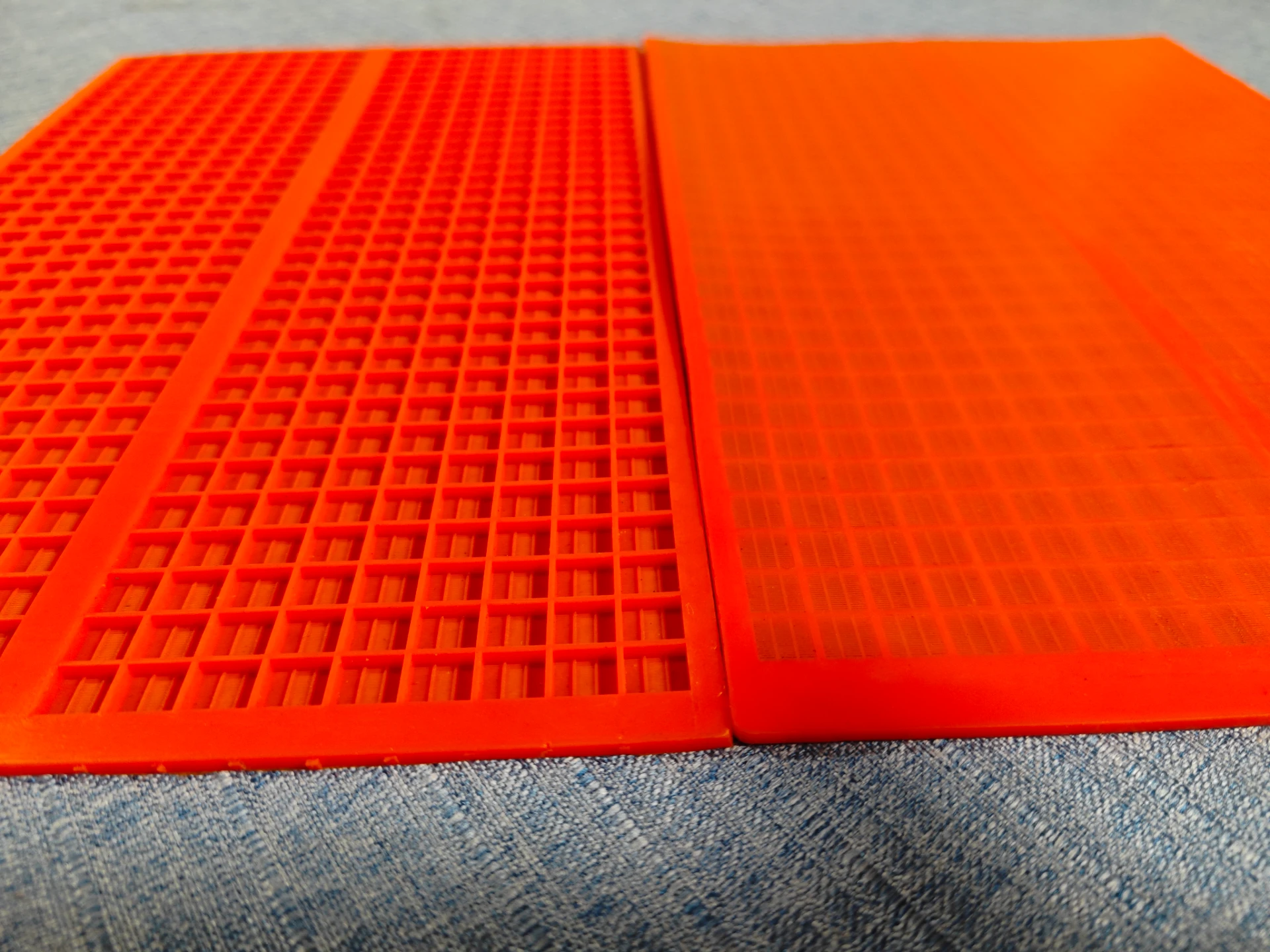

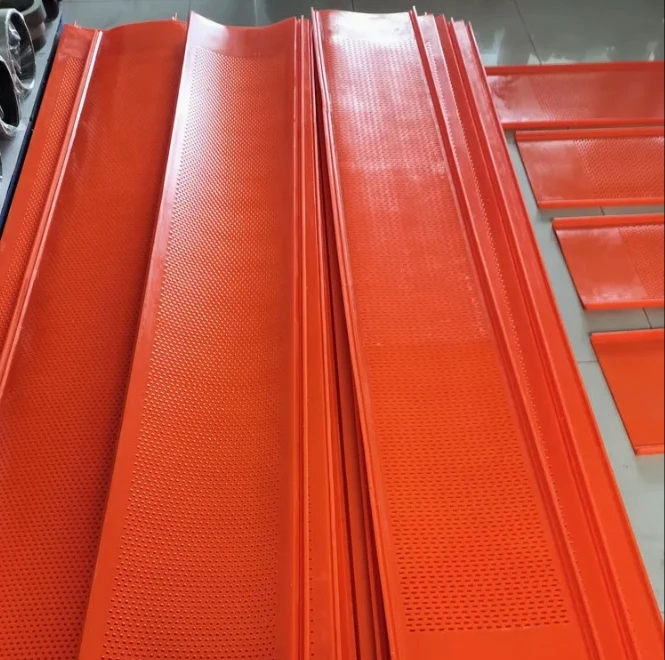

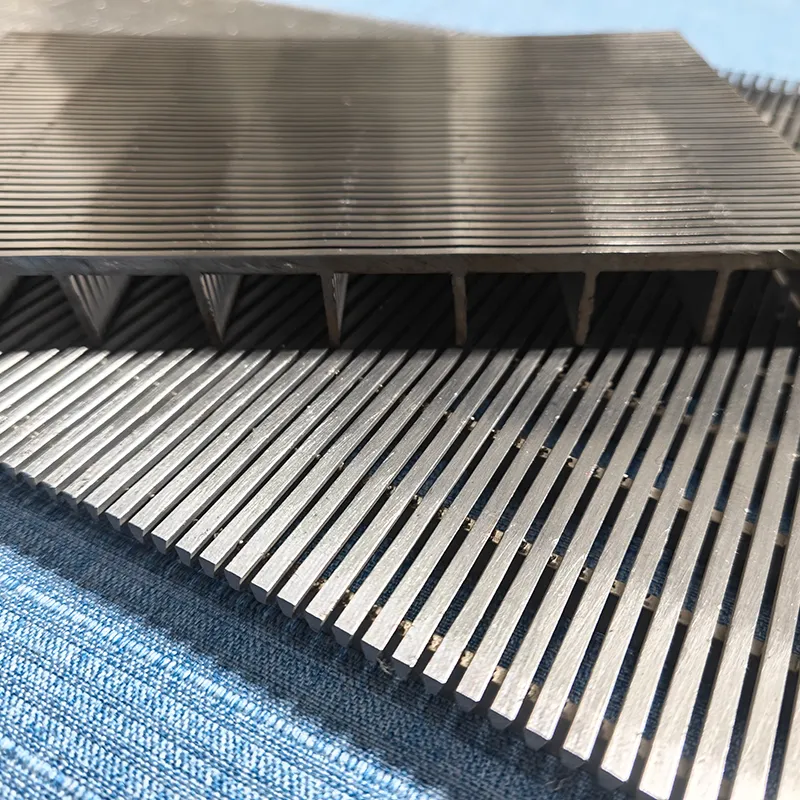

Engineering Superiority in Modern Cleaning Systems

Advanced scraper belt cleaner

s utilize polyurethane blades with 82% higher wear resistance than traditional rubber. Key innovations include:

- Auto-tensioning mechanisms maintaining 2.5-3.5 bar pressure

- Modular designs enabling 45-minute replacement vs. 4-hour downtime for legacy systems

- Multi-angle configurations for varying material viscosities

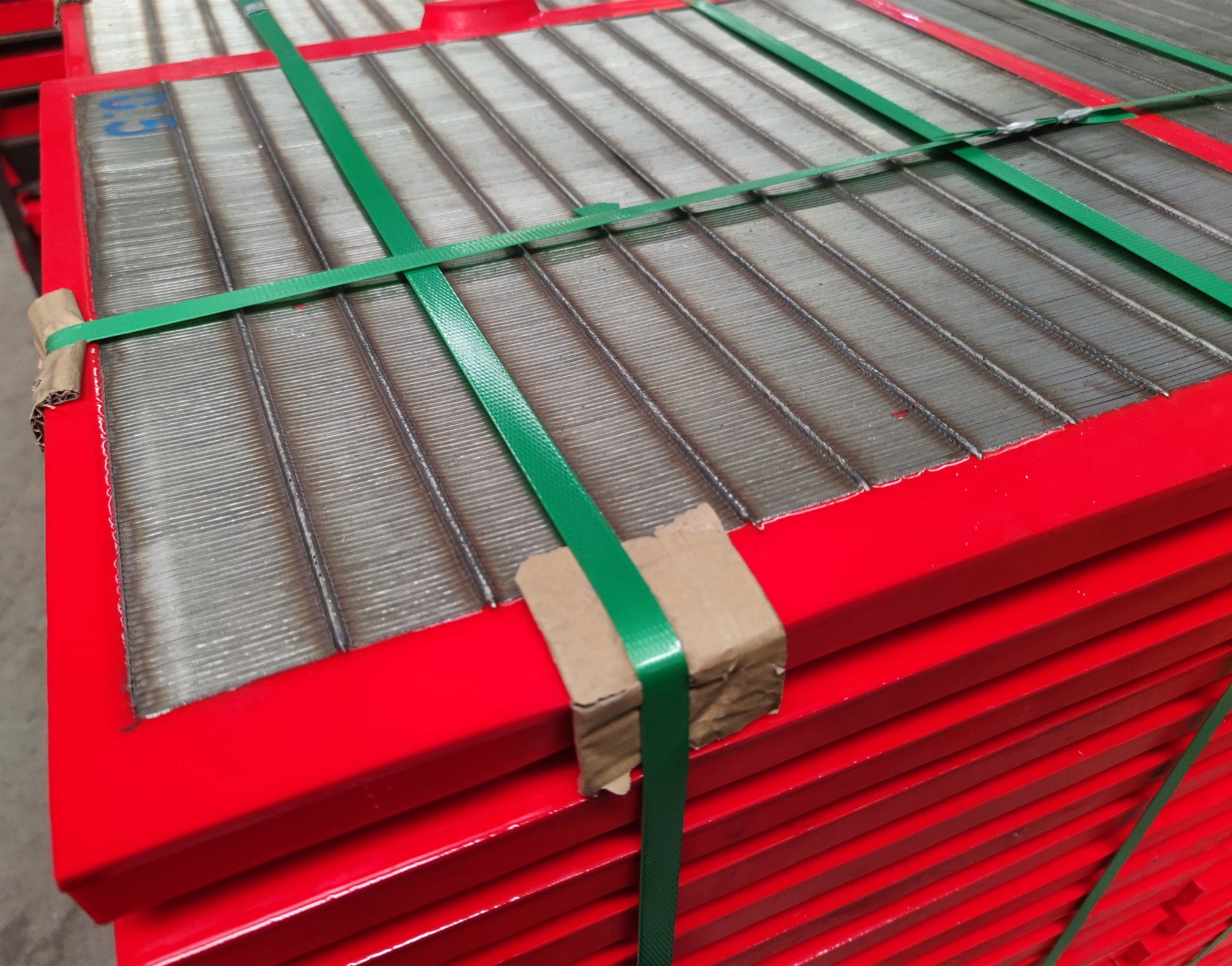

Industrial Benchmarking: Performance Metrics

| Brand | Blade Life (months) | Cleaning Efficiency | Max Temperature (°C) |

|---|---|---|---|

| Flexco XHD | 14-18 | 93.7% | 120 |

| Martin QC4 | 12-15 | 91.2% | 95 |

| ASGCO PreCleaner | 18-24 | 96.1% | 150 |

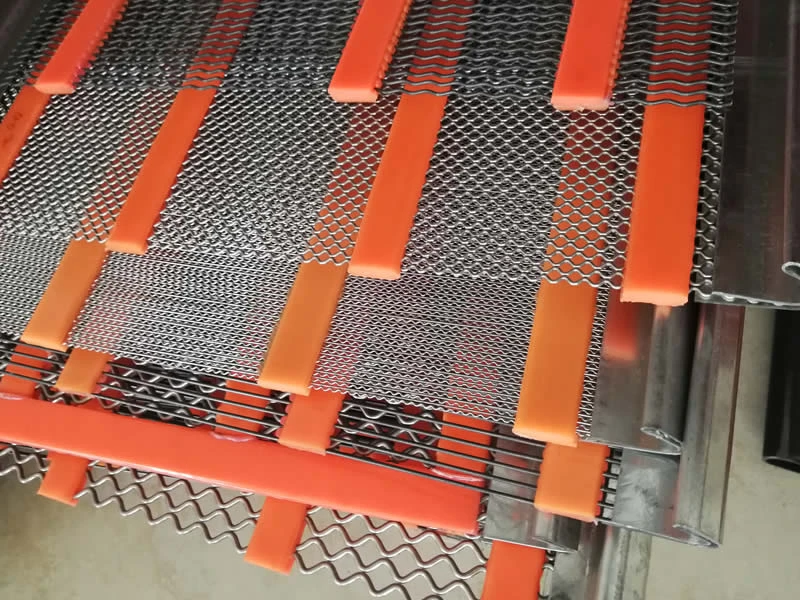

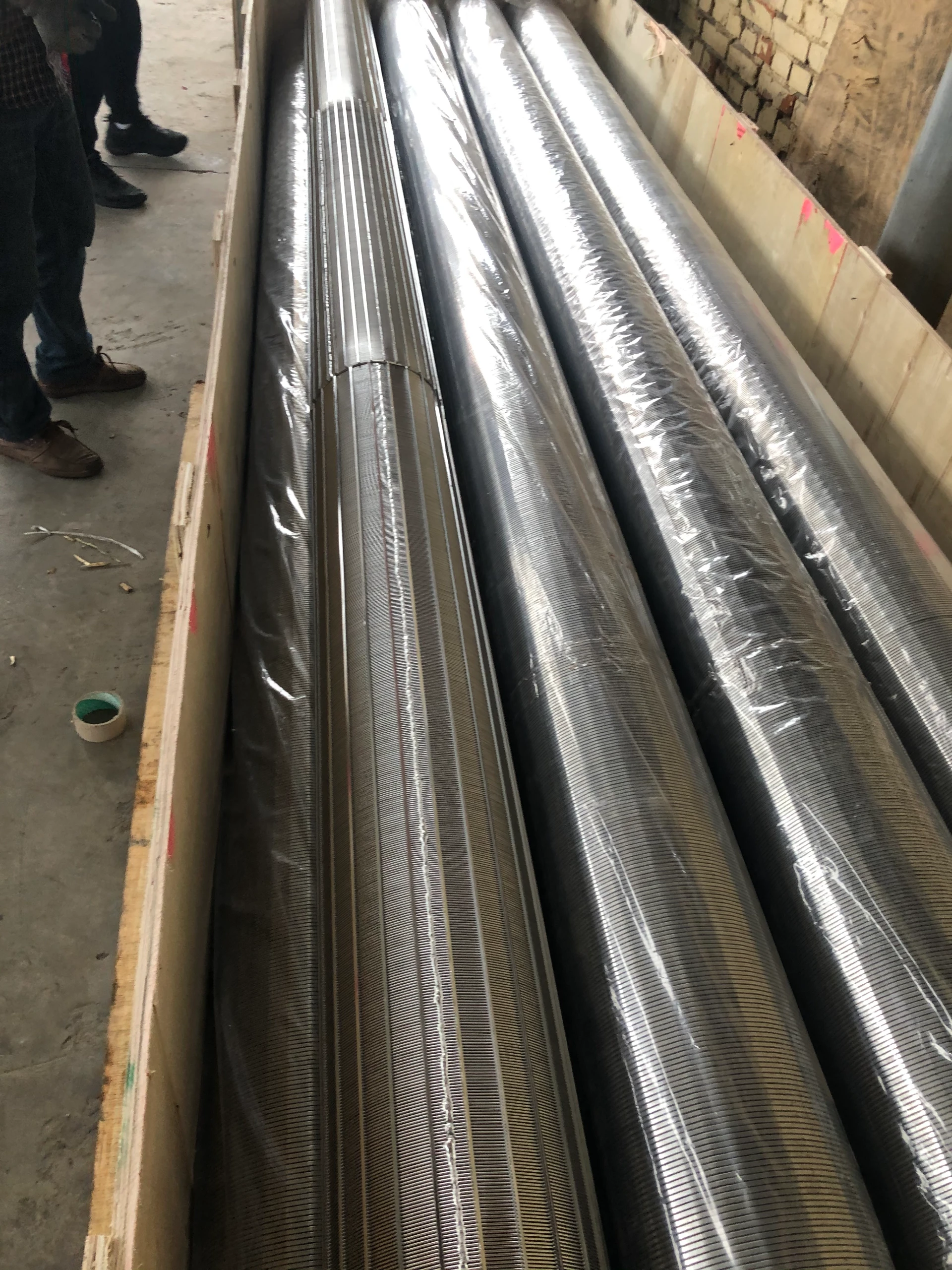

Tailored Solutions for Complex Applications

Custom-engineered conveyor belt cleaner scrapers adapt to:

- High-speed systems (>6m/s belt velocity)

- Extreme environments (-40°C to 180°C)

- Hygienic food-grade configurations

Material science advancements enable blade hardness customization from 70A to 95A Shore scale.

Real-World Impact: Copper Mine Deployment

A Chilean copper operation achieved:

- 37% reduction in belt replacement frequency

- Annual savings: $148,000 in maintenance costs

- 14.6% improvement in material throughput

The secondary belt cleaner installation paid back in 5.2 months through reduced spillage cleanup.

Economic Advantages of Proactive Maintenance

Lifecycle cost analysis shows:

- $9.50 saved per $1 invested in premium scrapers

- 63% lower environmental compliance costs

- 17-month ROI for automated tensioning systems

Scraper Belt Cleaner Evolution: Smart Systems

Emerging IoT-enabled cleaners provide:

- Real-time wear monitoring (±0.03mm accuracy)

- Predictive maintenance alerts via strain gauges

- Integration with plant-wide material tracking

Field tests demonstrate 31% longer component life through adaptive pressure control algorithms.

(scraper belt cleaner)

FAQS on scraper belt cleaner

Q: What is the primary function of a scraper belt cleaner?

A: A scraper belt cleaner removes residual material from conveyor belts to prevent buildup, reduce wear, and maintain efficient operation. It ensures cleaner transport and minimizes downtime.

Q: How does a conveyor belt cleaner scraper differ from other cleaning systems?

A: A conveyor belt cleaner scraper uses direct blade-to-belt contact to scrape off debris, while other systems might rely on brushes or sprays. It’s ideal for heavy-duty or sticky materials.

Q: Why is a secondary belt cleaner necessary in conveyor systems?

A: A secondary belt cleaner provides an additional cleaning stage to remove finer particles missed by the primary cleaner. This enhances belt lifespan and reduces maintenance costs.

Q: How often should a scraper belt cleaner be maintained?

A: Inspect scraper belt cleaners weekly for blade wear or damage. Replace blades or adjust tension as needed to ensure consistent cleaning performance.

Q: Can a conveyor belt cleaner scraper work on all belt types?

A: Most conveyor belt cleaner scrapers are adjustable and compatible with various belt materials. However, blade hardness and angle should match the belt type to avoid damage.