Elevating Material Separation: The Critical Role of Flip Flow Screens

In the demanding world of bulk material processing, efficient and precise separation is paramount. From mining and aggregates to recycling and industrial waste management, handling difficult-to-screen materials—those prone to blinding, pegging, or clogging—poses significant operational challenges. This is precisely where the innovation of flip flow screen for sale solutions comes into play. Unlike conventional vibratory screens, flip flow screens employ a unique dual-vibration system that dynamically flexes the screen mats, ensuring continuous self-cleaning and superior separation efficiency, even with wet, sticky, or fine materials. This technology is not merely an incremental improvement; it represents a paradigm shift in material processing, leading to higher throughput, reduced downtime, and lower operational costs across a multitude of industries.

The demand for robust and reliable screening solutions is escalating as industries strive for greater resource efficiency and higher product quality. Modern material handling operations require equipment that can withstand extreme conditions while delivering consistent performance. Flip flow screens, particularly those designed for heavy-duty applications, address these needs by offering unparalleled resistance to wear and tear, coupled with a design that minimizes maintenance requirements. Their ability to effectively process materials that would otherwise be rejected or require extensive pre-treatment positions them as a cornerstone technology for future-proof industrial operations.

The Engineering Excellence Behind Flip Flow Screens

Innovative Operating Principle

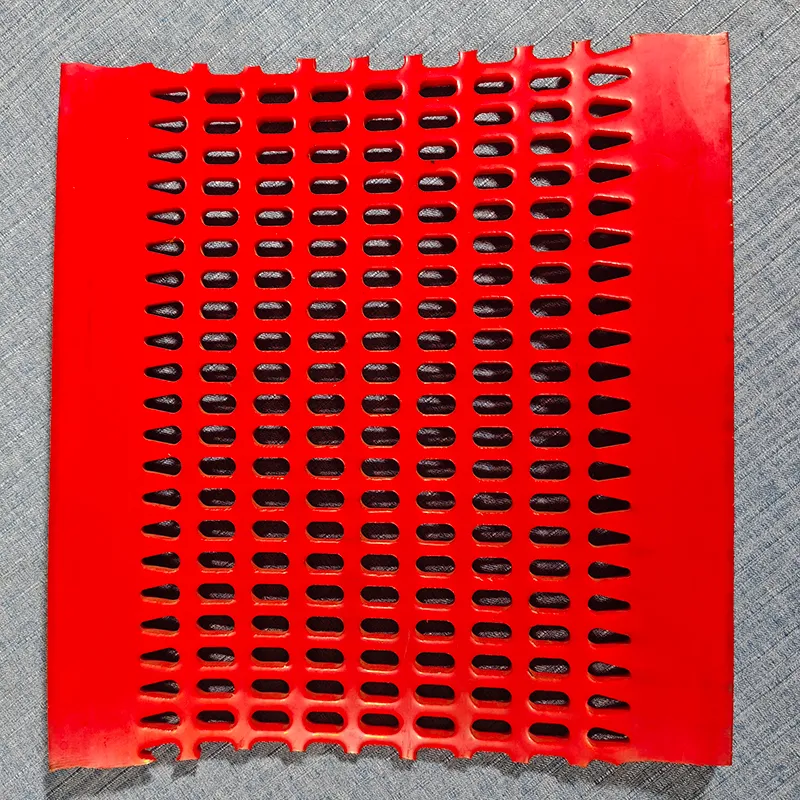

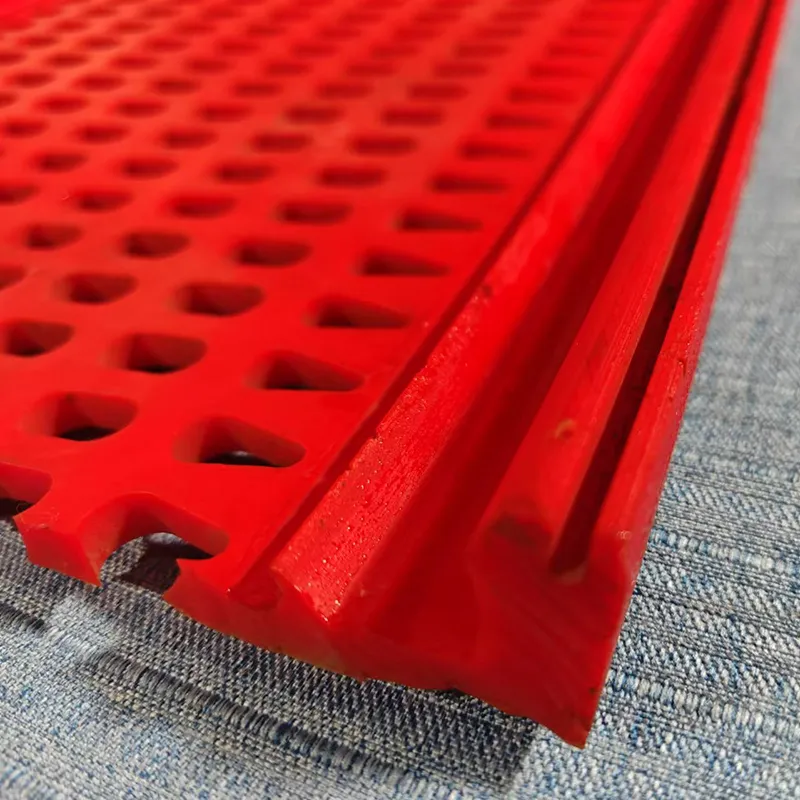

At the heart of every effective flip flow screen for sale is its ingenious operating principle. The system typically features two vibratory frames: an inner frame and an outer frame. The inner frame vibrates with a high acceleration, while the outer frame vibrates with a lower frequency and amplitude. This differential movement causes the highly elastic screen mats, often made of advanced polyurethane or rubber compounds, to stretch and contract rapidly—"flipping" and "flowing." This dynamic flexing generates accelerations up to 50g, significantly higher than traditional screens, effectively dislodging trapped particles and preventing blinding. This self-cleaning action is crucial for maintaining consistent separation efficiency, particularly when processing materials with high moisture content or a significant proportion of fines.

Manufacturing Process: Precision and Durability

The manufacturing of a premium flip flow screen for sale involves a meticulous process designed to ensure durability, precision, and optimal performance. Key components, such as the screen frames and vibrating units, are typically constructed from high-grade steel alloys through advanced fabrication techniques including precision cutting, welding, and CNC machining. This ensures structural integrity and dimensional accuracy. The screen mats themselves are often manufactured from specially formulated polyurethane or rubber, chosen for their elasticity, abrasion resistance, and long service life. These materials undergo rigorous quality control, including tensile strength tests and abrasion resistance evaluations, to meet stringent internal and international standards such as ISO 9001 for quality management and ANSI standards for component dimensions.

Throughout the assembly process, each component is thoroughly inspected. Bearing systems and eccentric shafts are balanced to minimize vibration and maximize operational longevity. Non-destructive testing (NDT) methods like ultrasonic testing and magnetic particle inspection are routinely employed to detect any hidden flaws in critical welded joints or castings. The typical service life of a well-maintained flip flow screen can extend beyond 10-15 years, depending on the application and material characteristics, far exceeding that of many conventional screen types. This longevity, coupled with robust anti-corrosion treatments, ensures a low total cost of ownership, making a flip flow screen for sale a strategic investment.

Technical Specifications & Performance Benchmarks

When evaluating a flip flow screen for sale, understanding its key technical parameters is essential for successful integration into existing processing lines and for optimizing operational output. These parameters define the screen's capacity, efficiency, and suitability for specific material types. Below is a representative table outlining critical specifications often found in high-performance flip flow screens, designed to process even the most challenging materials effectively and reliably.

| Parameter | Typical Range/Value | Explanation/Benefit |

|---|---|---|

| Screening Area | 2 m² to 20 m² per deck | Determines throughput capacity; larger area for higher volumes. |

| Screen Aperture Size | 2 mm to 100 mm (flexible) | Versatile for fine to coarse separation; easily customizable. |

| Vibration Frequency (Inner/Outer) | 10-15 Hz (Outer), 25-50 Hz (Inner) | High differential frequency prevents blinding, ensures self-cleaning. |

| Acceleration | Up to 50g on screen mats | Aggressive particle dislodgement for difficult materials. |

| Input Material Size | Up to 400 mm | Handles a wide range of feed sizes efficiently. |

| Power Consumption | 15 kW to 75 kW | Optimized for high performance with moderate energy footprint. |

| Screen Mat Material | Polyurethane / Specialty Rubber | High wear resistance, long life, excellent elasticity. |

| Noise Level | Typically | Engineered for quieter operation in industrial environments. |

These specifications highlight the robust capabilities of modern flip flow screen for sale units. The high acceleration rates ensure effective stratification and separation of fine particles, even those that are sticky or damp. This capability is particularly critical in industries where material quality directly impacts downstream processes and final product value. Understanding these technical nuances allows buyers to specify a screen that precisely matches their operational requirements, ensuring optimal return on investment.

Versatile Applications and Unrivaled Advantages

Applicable Industries and Scenarios

The adaptability of a flip flow screen for sale extends across a myriad of heavy industrial sectors, making it an invaluable asset where conventional screening technologies falter. These robust machines are extensively utilized in the coal industry, particularly for screening lignite, sticky run-of-mine coal, and wet fines, preventing the blinding common with static screens. In the aggregates and construction recycling sectors, they excel at processing demolition waste, recycled concrete, and contaminated soil, effectively separating out valuable aggregates from undesirable elements. Furthermore, the metallurgy sector benefits from their capacity to screen difficult ores, slags, and foundry sands.

Beyond these, flip flow screens find critical applications in waste management for municipal solid waste (MSW) and refuse-derived fuel (RDF) preparation, where materials are often highly heterogeneous and moist. The petrochemical industry leverages them for specialized solid-liquid separation tasks, and even the giving and drainage systems benefit from their robust design when handling slurries or wastewater treatment residues. Their ability to handle difficult, sticky, or fine materials makes them indispensable in scenarios where precise separation and high throughput are non-negotiable.

Key Technical Advantages

- Anti-Blinding Capability: The primary advantage is the dynamic self-cleaning action of the screen mats, which effectively prevents blinding and pegging, ensuring continuous and uninterrupted operation, even with highly cohesive or wet materials. This drastically reduces downtime and labor costs associated with manual cleaning.

- High Screening Efficiency: Due to the aggressive acceleration (up to 50g), flip flow screens achieve superior stratification of the material bed, allowing fine particles to quickly pass through the screen openings. This results in higher separation efficiency and purer products compared to traditional vibrating screens.

- Versatility in Material Handling: From moist coal and sticky clay to abrasive aggregates and municipal waste, these screens are engineered to handle a diverse range of challenging materials that would typically clog or wear out conventional screen media.

- Enhanced Durability and Lifespan: Utilizing high-quality polyurethane or specialty rubber screen mats, coupled with robust steel frame construction, ensures exceptional resistance to abrasion and impact, leading to extended operational life and reduced maintenance frequency.

- Energy Efficiency: Despite their high performance, many modern flip flow screen for sale models are designed with optimized drive systems that minimize energy consumption relative to their throughput, contributing to lower operational expenditures and greater sustainability.

Selecting Your Supplier: Manufacturer Insights & Custom Solutions

Choosing the right supplier for a flip flow screen for sale is as crucial as selecting the screen itself. Reputable manufacturers distinguish themselves through adherence to stringent quality control, comprehensive engineering expertise, and proven track records. Key differentiators include a manufacturer's commitment to R&D, reflected in patented designs and continuous product innovation. Furthermore, their experience in specific industry verticals, such as providing tailored bivitec flip flow screens for challenging mineral processing, often translates into optimized performance and reliability. Evaluating suppliers based on their certifications (e.g., ISO 9001:2015), the transparency of their testing data, and the availability of performance guarantees can significantly mitigate procurement risks.

Customization and Tailored Solutions

One of the most valuable aspects of partnering with a leading flip flow screen manufacturer is the ability to obtain highly customized solutions. Given the unique properties of various materials and the diverse operational contexts, a one-size-fits-all approach is rarely optimal. Customization options for a flip flow screen for sale can include:

- Tailored Screen Apertures and Mat Configurations: Adjusting hole sizes, shapes, and mat thicknesses to precisely match desired separation curves and material characteristics.

- Variable Frequency Drives: Integrating advanced control systems that allow for real-time adjustment of vibration frequencies and amplitudes, optimizing performance for fluctuating feed conditions.

- Material of Construction: Utilizing specialized steel alloys or coatings for enhanced corrosion resistance in highly aggressive chemical environments, or for extreme abrasive applications.

- Modular Design Integration: Designing units that seamlessly integrate into existing plant layouts, considering space constraints, material flow, and maintenance access.

- Dust Enclosures and Suppression Systems: Implementing comprehensive solutions to meet stringent environmental regulations and improve workplace safety.

This level of customization ensures that the investment in a flip flow screen for sale yields maximum operational efficiency and long-term value, directly addressing the unique challenges of specific processing lines.

Real-World Performance: Case Studies & Industry Impact

The tangible benefits of investing in a high-quality flip flow screen for sale are best illustrated through real-world applications and documented improvements. For example, a major coal mining operation in North America, facing severe blinding issues with traditional screens when processing high-moisture coal fines, implemented a series of flip flow screens. Post-installation data indicated a 35% increase in screening efficiency, a 60% reduction in unscheduled downtime due to blinding, and a significant improvement in the quality of their coal product, leading to higher market value. This demonstrates the profound impact these screens can have on productivity and profitability.

Similarly, a European recycling facility specializing in construction and demolition waste observed a remarkable transformation after integrating a large-scale flip flow screen. They were able to effectively separate aggregates from contaminated soil, plastics, and wood, which was previously a labor-intensive and inefficient process. The flip flow screen for sale enabled them to recover marketable aggregate fractions, significantly reducing landfill waste and opening new revenue streams. These case studies underscore the technology's capacity to overcome complex material separation challenges, driving both operational efficiency and environmental sustainability.

Frequently Asked Questions (FAQ)

Q1: What materials are best suited for a flip flow screen?

Flip flow screens are ideally suited for processing challenging materials that are prone to blinding or clogging with traditional screens. This includes wet and sticky materials such as moist coal, lignite, clay, compost, municipal solid waste (MSW), recycling materials (e.g., shredded plastic, rubber), minerals with high moisture content, and construction and demolition waste. Any material containing a significant proportion of fines or moisture will benefit significantly from a flip flow screen for sale.

Q2: How do flip flow screens prevent blinding?

The primary mechanism for anti-blinding in flip flow screens lies in their unique dual-vibration system. The screen mats are not rigidly fixed; instead, they are highly elastic and dynamically stretched and relaxed at high frequencies (up to 50 Hz). This rapid flexing creates a "trampoline" effect, continuously dislodging particles that would otherwise stick to or peg in the screen apertures, thus ensuring consistent and efficient material flow.

Q3: What is the typical lifespan and maintenance requirement for these screens?

High-quality flip flow screen for sale units, especially those with durable polyurethane screen mats and robust construction, typically offer a service life of 10-15 years, often more, with proper maintenance. Maintenance primarily involves routine checks of drive components, lubrication, and inspection of screen mats for wear. The self-cleaning nature significantly reduces the need for manual screen cleaning, contributing to lower operational costs and extended intervals between major overhauls.

Partnership & Support: Ensuring Your Investment

Acquiring a flip flow screen for sale is a strategic investment requiring robust support. Leading manufacturers provide comprehensive pre-sales consultation, including material testing services to ensure the optimal screen configuration for your specific application. Post-purchase, clients can expect detailed installation guidance, operator training, and readily available spare parts to minimize downtime.

Delivery timelines typically range from 8 to 16 weeks, depending on customization levels and current production schedules. Reputable suppliers offer a standard warranty of 12-24 months on mechanical components, often with extended warranties available for critical parts like vibrator motors. Furthermore, comprehensive customer support, including remote diagnostics and on-site technical assistance, ensures your operations run smoothly for years to come. This commitment to long-term partnership ensures that your investment in a flip flow screen is not just a purchase, but a lasting solution.

References

- ISO 9001:2015 Quality Management Systems – Requirements. International Organization for Standardization.

- ASTM International Standards on Sieves and Wire Screen Cloth. ASTM International.

- Mineral Processing Design and Operations: An Introduction, by Ashok Gupta and Denis S. Yan. Elsevier, 2006.

- Screening and Size Separation. Online Handbook of Mineral Processing.