In the field of ore processing, Diamond Mining Screens have become an important tool for separating materials based on size, shape, or density due to their outstanding performance, occupying a critical position in mining production. Its efficient and precise separation ability greatly improves the efficiency and quality of ore processing, laying a solid foundation for subsequent processing procedures.

Diamond Mining Screens achieve efficient material separation based on clever design and exquisite craftsmanship

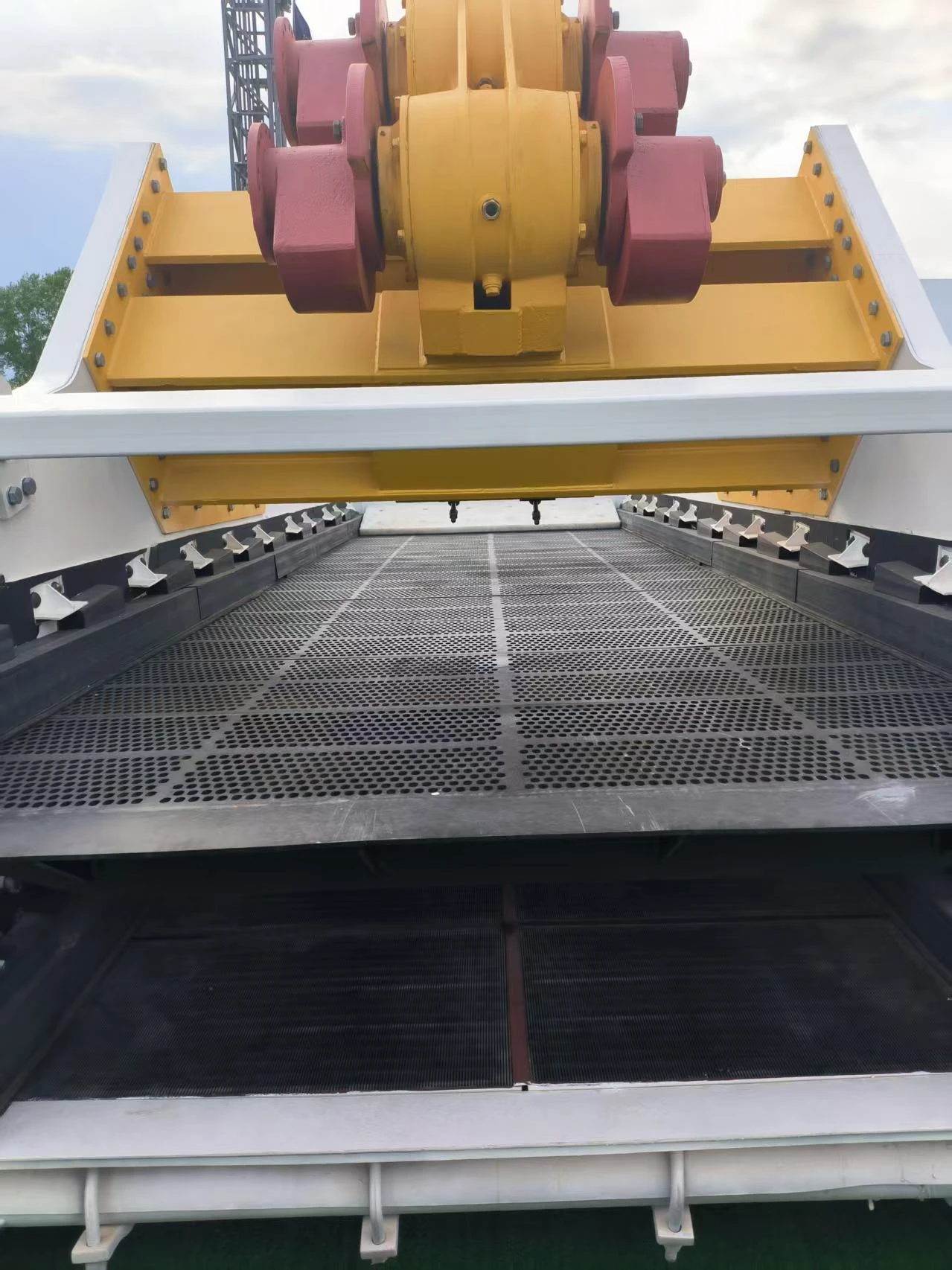

The mesh size of vibrating mining screens is accurately calculated and strictly controlled, and can accurately screen materials of different particle sizes based on differences in ore size, completing size separation. At the same time, the unique mesh structure and movement mode enable ores with different shapes to present different motion trajectories on the sieve surface, thereby achieving shape separation; In addition, by coordinating with media such as water flow and utilizing the density differences of different materials, density separation is achieved during the movement process to ensure the comprehensiveness and accuracy of material separation.

Diamond Mining Screens demonstrate significant advantages in material separation processes

The high-strength material endows it with strong load-bearing capacity, capable of withstanding the impact of large flow and heavy ore, ensuring stable and continuous separation work; Excellent wear resistance and corrosion resistance make it durable in harsh mining environments, reducing replacement frequency and lowering maintenance costs; The extremely high screening accuracy ensures the accuracy of material separation, effectively avoiding material mixing and providing high-quality raw materials for subsequent processing.

Diamond Mining Screens play an indispensable role in multiple stages of ore processing

In the initial screening stage, iron ore screening quickly separates large waste rocks from ore that meets the requirements, improving mining efficiency; In the fine separation stage, precise grading is carried out for ores with different particle sizes, shapes, and densities, separating diamond containing ores from other impurities, enriching diamond resources, and improving ore utilization efficiency; In tailings treatment, the separation of residual useful minerals reduces resource waste and achieves green and environmentally friendly mining.

With the rapid development of technology, Diamond Mining Screens continues to innovate and upgrade

The application of new composite materials further enhances the comprehensive performance of mining screen mesh, making it more efficient and stable during material separation; The integration of intelligent monitoring system can monitor the working status and separation effect of Diamond Mining Screens in real time, adjust parameters in a timely manner, and ensure separation accuracy; The application of automation technology reduces human intervention, improves separation efficiency and consistency, and meets the large-scale and refined production needs of modern mining.

In summary, trash screen mining has become an important tool for separating materials based on size, shape, or density due to its scientific design, excellent performance, and constantly innovative technology. It runs through all aspects of ore processing, providing strong support for improving mining production efficiency, ensuring product quality, and achieving efficient resource utilization. It plays an irreplaceable key role in the development process of modern mining.

Diamond Mining Screens FAQs

What is the main function of Diamond Mining Screens?

Diamond Mining Screens are mainly used for grading and separating ores during the mining process. By using the aperture differences of Diamond Mining Screens, different sizes of diamond raw ore or crushed stone are classified to ensure the efficiency of the subsequent sorting process.

How do Diamond Mining Screens separate materials based on size?

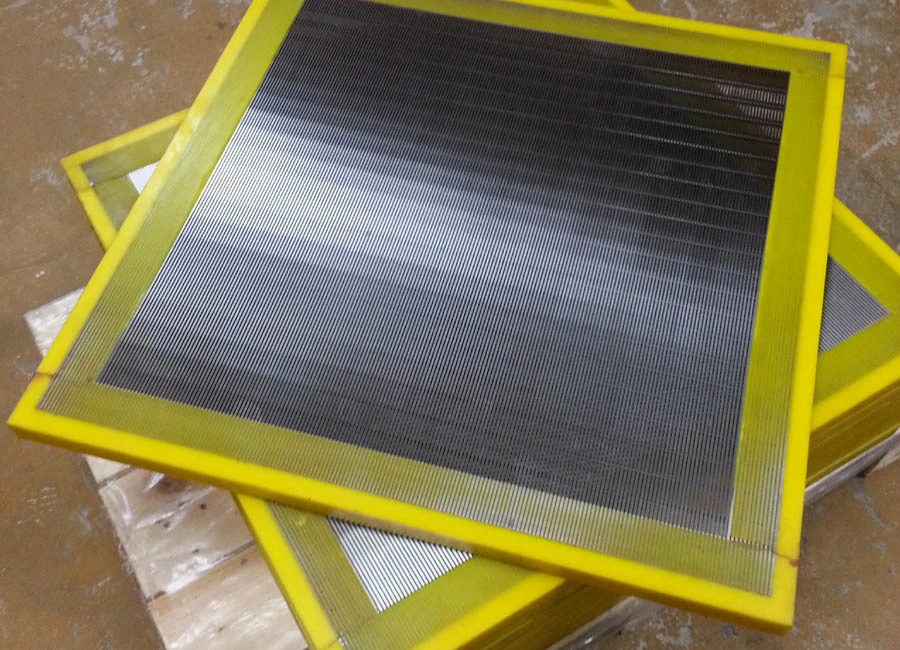

Diamond Mining Screens adopt a multi-layer design, with each layer's aperture gradually decreasing from large to small. After vibration or water flow erosion, larger particles of ore remain in the upper layer, while smaller particles (such as diamonds) fall into the lower layer, achieving precise size sorting.

How is shape separation achieved in Diamond Mining Screens?

Specially designed sieve surfaces (such as wavy or inclined sieve plates) utilize the rolling characteristics of ore to allow circular or smooth particles (such as diamonds) to pass through the sieve holes faster, while blocking impurities in the form of flakes or sharp edges.

What is the relationship between density sorting and Diamond Mining Screens?

Some screening equipment combines the principle of density difference, such as heavy medium screening. By adjusting the water flow rate or using heavy liquid, high-density diamonds will settle to the bottom while light impurities are washed away.

What are the key advantages of Diamond Mining Screens?

Efficient and energy-saving, can significantly reduce manual sorting costs; Strong adaptability, able to handle different types of mineral sands; Accurate separation, improving diamond recovery rate and reducing impurity interference.