In the complex process of diamond mining and ore processing, Diamond Mining Screens, as a key equipment, undertake the important tasks of ore crushing, screening, and sorting. Their performance directly affects the efficiency of ore processing and the quality of diamond mining.

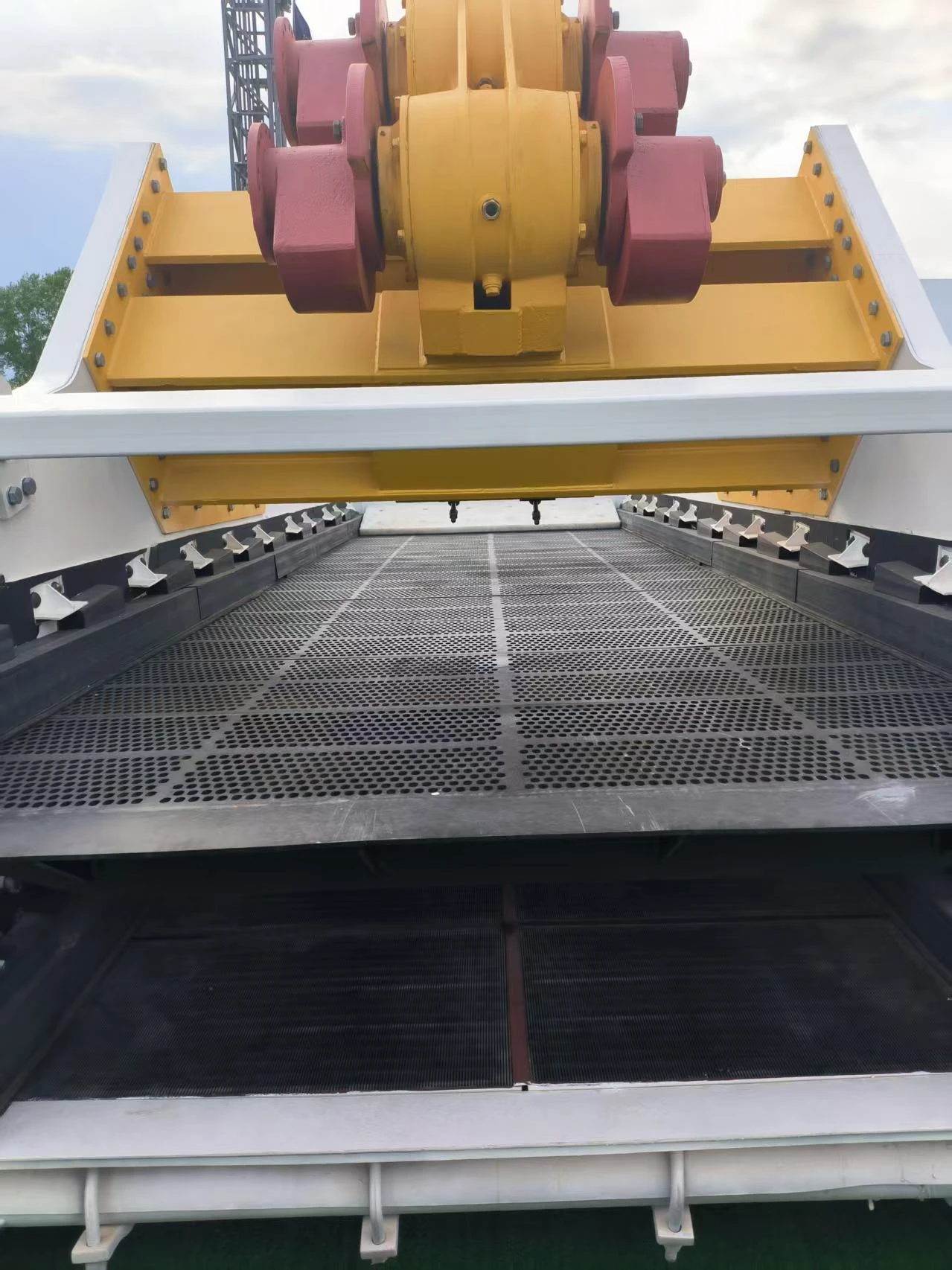

Diamond Mining Screens achieves efficient operations through scientific structural design and precision manufacturing processes

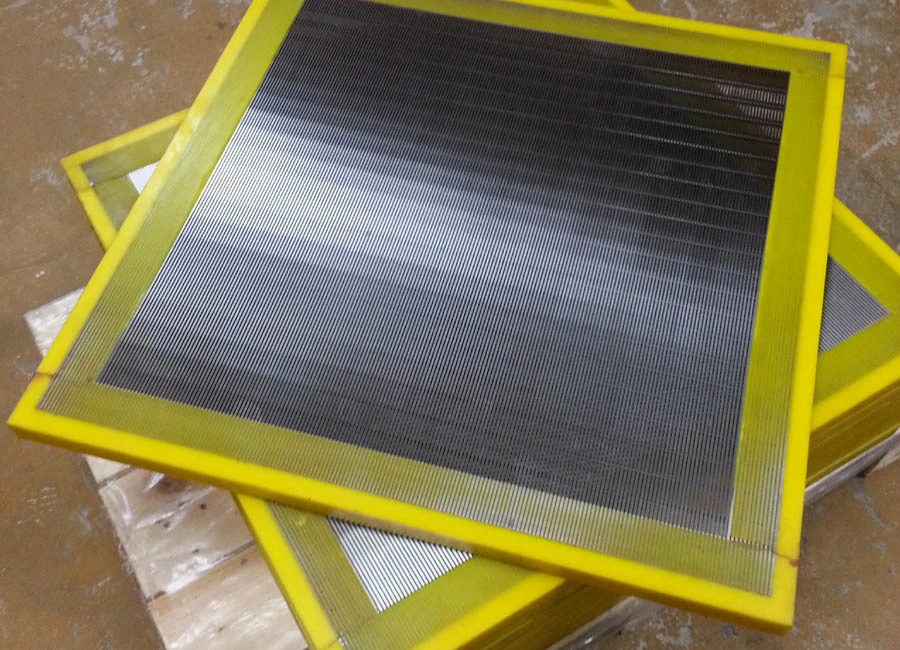

Diamond Mining Screens use high-strength and corrosion-resistant materials, combined with advanced weaving technology, to ensure a smooth mesh surface and precise mesh opening. During work, mechanical movements such as vibration or rotation are used to continuously move the ore on the screen surface. Different particle sizes of ore are classified and screened based on the aperture size of the vibrating mining screens. At the same time, the special surface texture of Diamond Mining Screens can effectively prevent ore adhesion and blockage, ensuring a smooth and efficient screening process.

Diamond Mining Screens have significant advantages in ore processing

Its high-strength structure enables it to withstand the impact and heavy pressure of large ore blocks, maintain stable performance in harsh mining environments, and reduce the frequency of damage; Excellent wear resistance extends the service life of iron ore screening and reduces equipment maintenance costs; The precise mesh design ensures screening accuracy and can accurately separate ores of different particle sizes, providing high-quality raw materials for subsequent sorting processes and improving the purity and efficiency of diamond mining.

Diamond Mining Screens are widely used in multiple key processes such as ore crushing, screening, and sorting

In the crushing stage, the mining screen panels assist the crusher in preliminary screening of the mined ore, separating out large pieces of ore that do not meet the requirements and returning them to the crusher for re crushing, thereby improving crushing efficiency; During the screening process, the ore is finely graded according to different job requirements to separate ore products with different particle sizes; In the sorting process, by cooperating with other beneficiation equipment, diamond containing ores are screened out, useless waste rocks are removed, and efficient utilization of ores and diamond enrichment are achieved.

With the advancement of mining technology, Diamond Mining Screens are also constantly innovating

The application of new materials further improves the performance of mining sieves, such as the use of new polymer composite materials, which enhance the toughness and wear resistance of Diamond Mining Screens; The integration of intelligent technology has enabled real-time monitoring and fault warning of the working status of Diamond Mining Screens, facilitating timely maintenance and adjustment, and improving equipment operation stability; The increase in automation has reduced manual operations, lowered labor intensity, and improved overall production efficiency.

In summary, Diamond Mining Screens play an irreplaceable role in ore crushing, screening, and sorting processes due to their excellent performance and unique design. Whether it is improving the efficiency of ore processing or ensuring the quality of diamond mining, it provides a solid guarantee for the stable operation and efficient development of mining production, and is an indispensable important equipment for modern diamond mining and ore processing industries.

Diamond Mining Screens FAQs

1: What is the core function of Diamond Mining Screens?

Mainly used for grading, desliming, and pre selection of diamond ores. By using equipment such as vibrating screens and drum screens, the crushed ore is separated by particle size, and waste rock and fine mud are removed to improve the efficiency of subsequent sorting (such as reselection and X-ray sorting) and reduce processing costs.

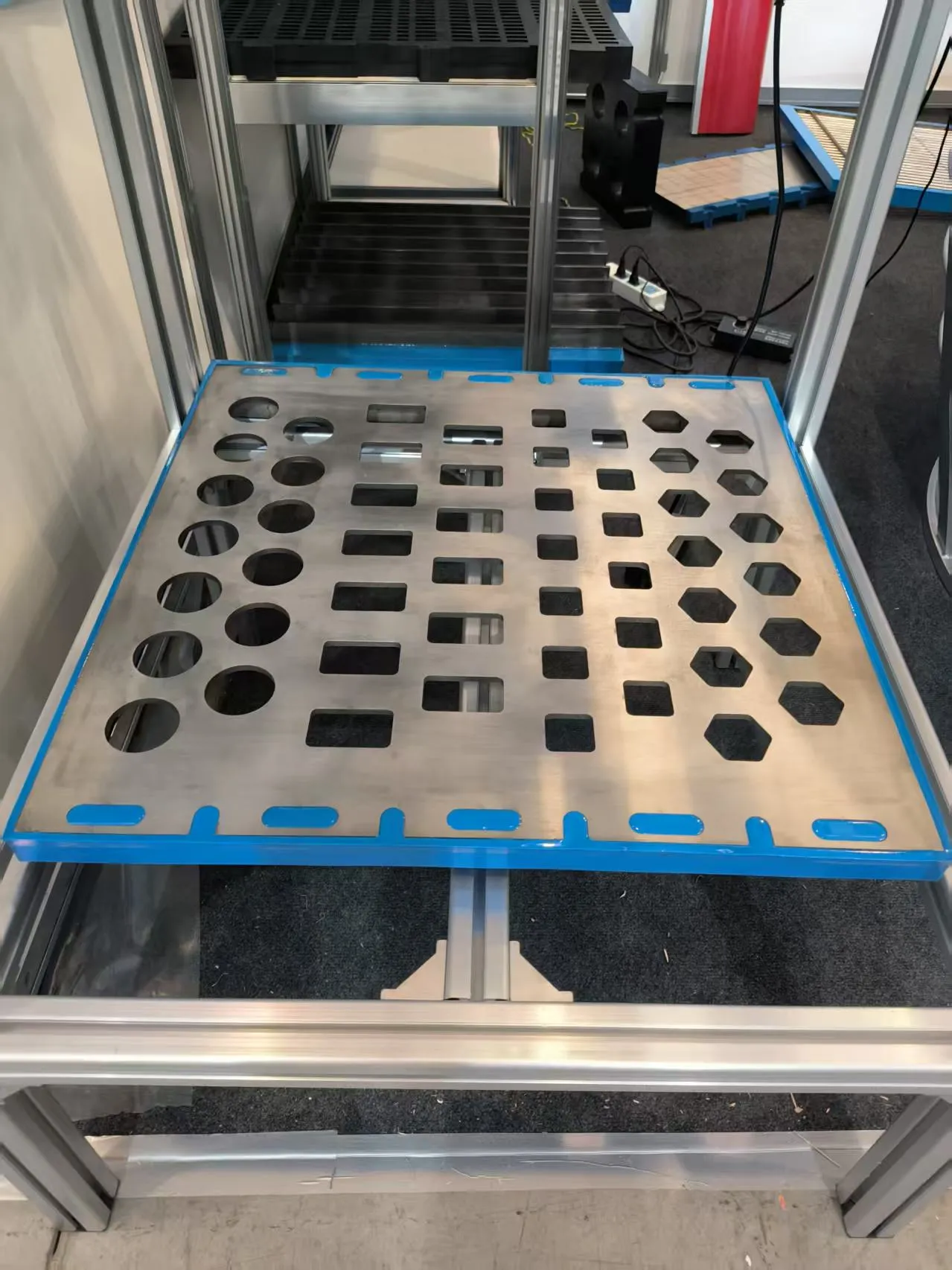

2: What are the common types of Diamond Mining Screens?

It is mainly divided into three categories:

Vibration screen: High frequency vibration screen is suitable for desliming fine-grained ores, while linear vibration screen is used for grading medium coarse particles.

Drum screen: used for coarse screening of viscous ores through a rotating screen cylinder, commonly used in the ore washing process.

Grille screen: used for pre screening of block ores before primary crushing, quickly separating oversized waste rocks.

3: How can Diamond Mining Screens optimize screening efficiency to reduce diamond loss?

The key measures include:

Adjust sieve parameters: Choose stepped Diamond Mining Screens or composite sieve plates based on the particle size distribution of the ore.

Control the feeding speed: avoid overloading that may cause insufficient screening of fine-grained diamonds.

Cooperate with water washing process: Viscous ores need to be washed with water to prevent Diamond Mining Screens from clogging.

4: What are the challenges facing diamond mining screens?

The main difficulty lies in the complex characteristics of the ore

The high mud content makes it easy to paste the screen, and regular cleaning or the use of self-cleaning Diamond Mining Screens is required.

The diamond embedding has uneven particle size and requires multi-stage screening (such as coarse, medium, and fine grades).

Hard rock wear equipment requires the use of wear-resistant steel or rubber lining.

5: How to integrate Diamond Mining Screens with subsequent sorting processes?

Usually used as a preprocessing step:

The screened products (large particles) may return to the crusher or enter the heavy medium sorting.

The screened product (qualified particle size) enters the jigs, X-ray sorting machines, etc. to extract diamonds.

The fine particles after desliming can be processed through special processes such as oil paste beneficiation.