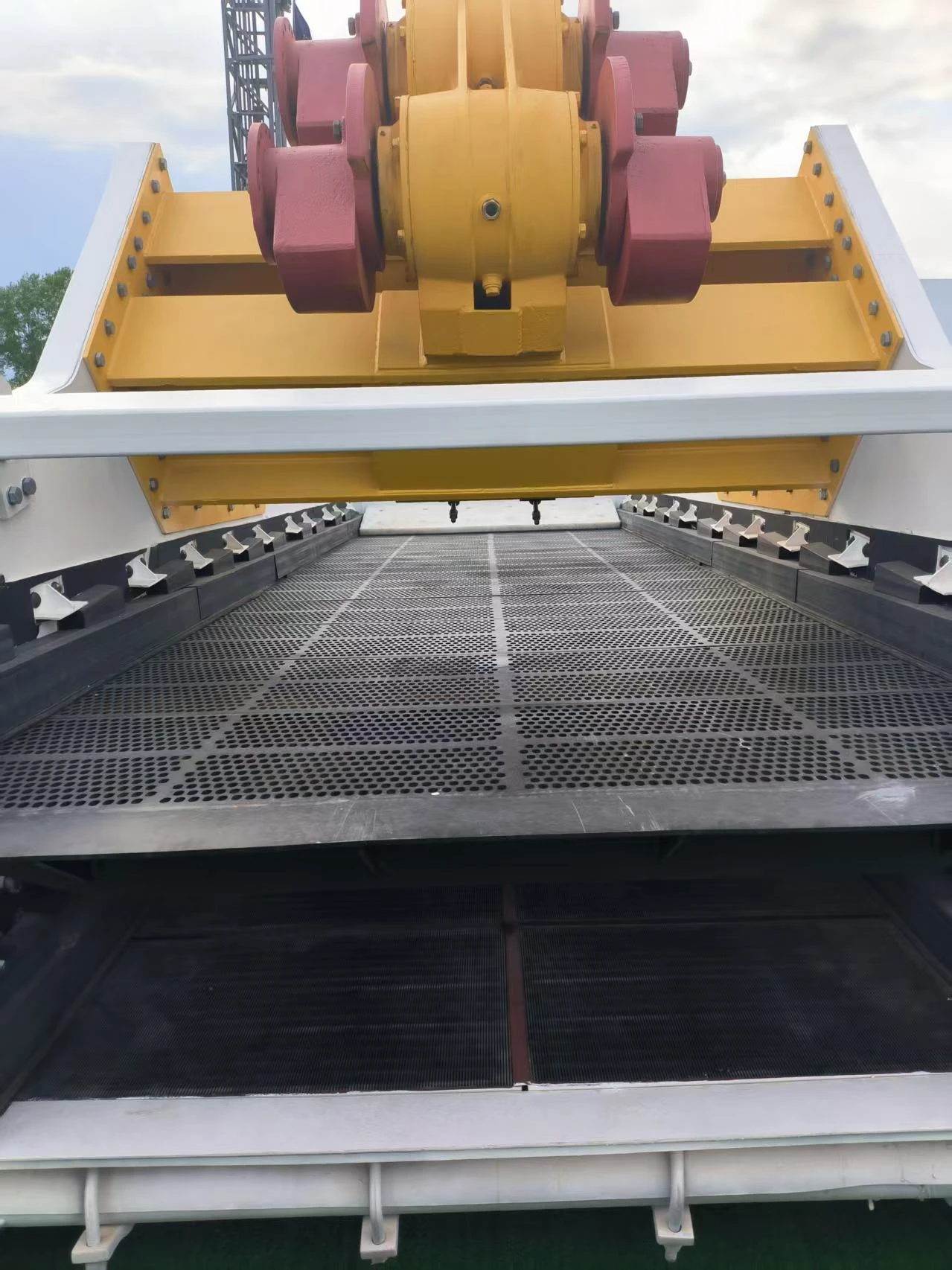

In the current era of continuous innovation in industrial filtration technology, Static Wedge Wire Screen, with its unique structural design and outstanding performance, has become an ideal choice for achieving high flow rate and efficient filtration. Its widespread application in many industrial fields demonstrates irreplaceable value.

The working principle of Static Wedge Wire Screen is based on the precise combination of wedge wire and support bar

The vee wire filter screen has a trapezoidal cross-section, arranged parallel to each other, with support bars fixed at a certain distance to form a stable gap structure. When high-speed fluid passes through, solid particles are intercepted on the screen surface due to their size being larger than the gap, while the fluid penetrates smoothly. This structure ensures rapid fluid passage and precise filtration under high flow rate conditions, effectively avoiding filtration failure caused by excessive flow rate.

The advantages of Static Wedge Wire Screen are fully demonstrated in industries such as oil extraction, wastewater treatment, and food processing

In the underground operation of oil extraction, the high-speed flowing oil flow is mixed with impurities such as rock debris, and the vee wire screen can quickly filter them to ensure stable oil production in the oil well; When treating high flow sewage, sewage treatment plants can efficiently intercept suspended solids without affecting the efficiency of sewage treatment; In the field of food processing, static wedge wire screens can filter impurities and ensure product quality when dealing with high-speed fluid raw materials, without affecting production progress.

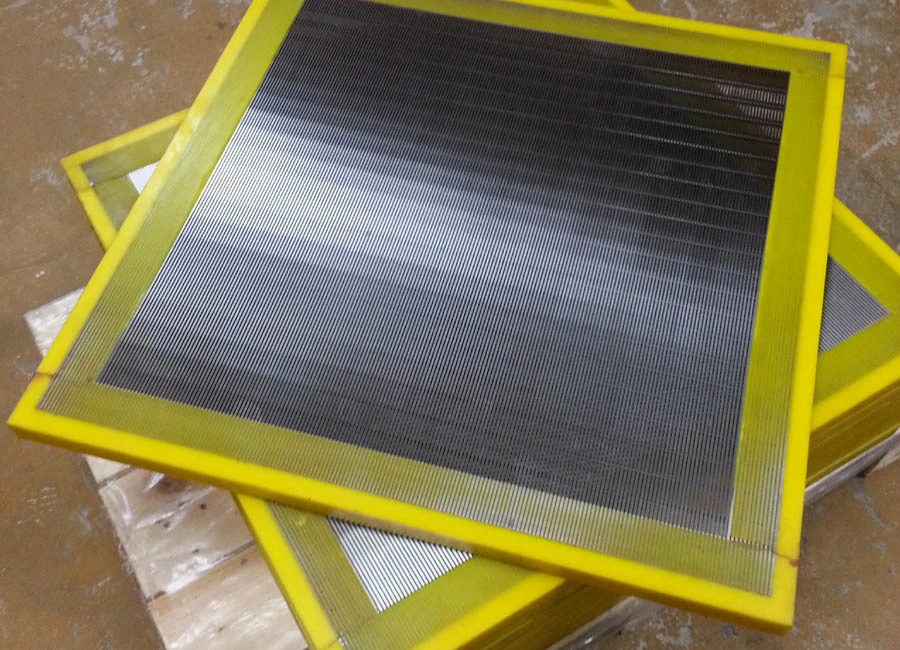

From the perspective of structure and material, Static Wedge Wire Screen has extremely high stability and durability

The wedge-shaped wire is firmly connected to the support bar through processes such as resistance welding, forming a rigid frame that can withstand the impact force and pressure brought by high velocity fluids. Stainless steel, titanium alloy and other corrosion-resistant materials are commonly used, which can work stably for a long time in complex environments such as acid and alkali, ensuring that the filtration performance does not significantly deteriorate with time and environmental changes, providing long-lasting protection for high flow rate filtration.

With the continuous improvement of industrial requirements for filtration efficiency and quality, Static Wedge Wire Screen is also continuously innovating and developing---h2

Researchers have further enhanced its performance in high flow rate filtration by optimizing gap size design, improving welding processes, and developing new materials. It is expected to play a greater role in more demanding industrial scenarios in the future.

In summary, the wedge wire screen pipe, with its unique working principle, extensive application advantages, stable structural materials, and promising development prospects, has become an important guarantee for effective filtration at high flow rates. Static Wedge Wire Screen solves the problem of balancing high flow rate and efficient filtration for industrial production, promoting the development of various industries towards high efficiency and stability, and occupies an important position in the field of industrial filtration.

Static Wedge Wire Screen FAQs

What is Static Wedge Wire Screen?

Static Wedge Wire Screen(Static Wedge Wire Screen) It is a filtering device made by welding or winding wedge-shaped metal wires (usually stainless steel). Its unique wedge-shaped wire structure forms uniform gaps, enabling efficient filtration at high flow rates, suitable for solid-liquid separation of liquids or gases, particle interception, and other scenarios.

How can Static Wedge Wire Screen achieve effective filtering at high flow rates?

The cross-section of the wedge-shaped wire is trapezoidal, and the gap gradually narrows from the inlet to the outlet. This design can reduce particle blockage while allowing fluid to pass through quickly. The high opening area (usually 5% -40%) and smooth flow channel surface further reduce pressure loss, ensuring stable filtration accuracy even during high-speed flow.

What are the main application areas of Static Wedge Wire Screen?

Water treatment: such as seawater desalination pretreatment and screening in wastewater treatment.

Petrochemical industry: Separation of impurities or catalysts from crude oil.

Food and beverage: Filter liquid foods such as fruit juice and beer.

Mining: slurry grading or tailings dewatering.

Energy: Impurity filtration of gas or steam.

What are the advantages of Static Wedge Wire Screen compared to other filtering screens?

Strong anti clogging ability: The wedge-shaped structure reduces particle blockage and extends service life.

High strength: The welding process makes the screen resistant to high pressure and mechanical impact.

Easy to clean: can be backwashed or cleaned with ultrasonic waves, with low maintenance costs.

Flexible customization: The gap size (usually 25 μ m25mm) and material (such as 316L stainless steel) can be adjusted as needed.

What key parameters should be considered when making a selection?

Gap accuracy: determined by particle size, such as intercepting particles ≥ 100 μ m with a 100 μ m gap.

Corrosion resistance of materials: In acidic environments, corrosion-resistant materials such as Hastelloy should be selected.

Traffic demand: High flow rates require matching with larger opening areas or diameters.

Installation method: It is necessary to adapt to the flange/threaded interface of the pipeline or equipment.