Unlocking Efficiency in Mineral Processing: The Versatility of Polyurethane Mesh

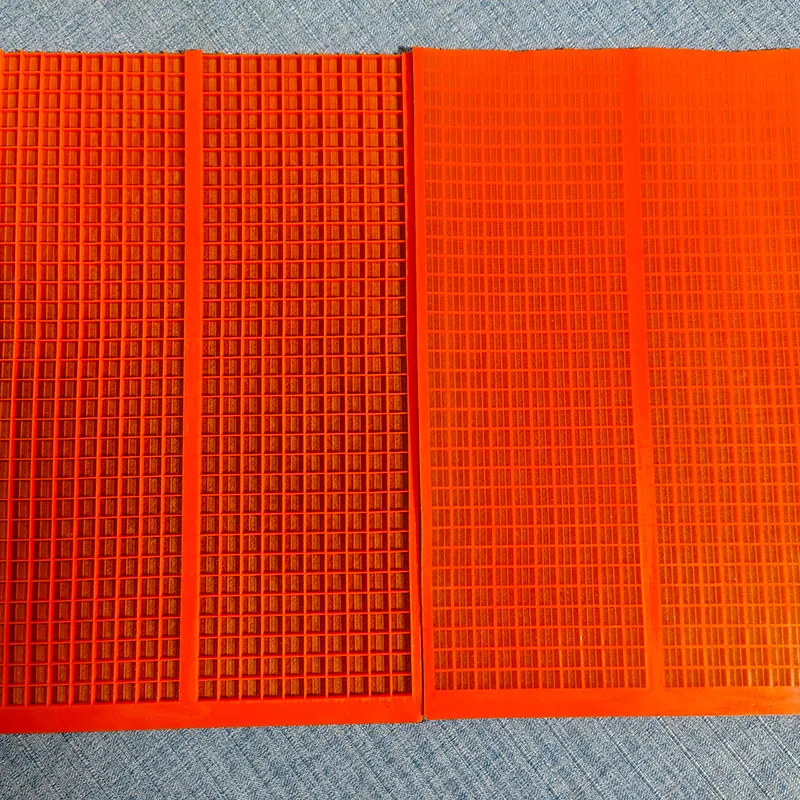

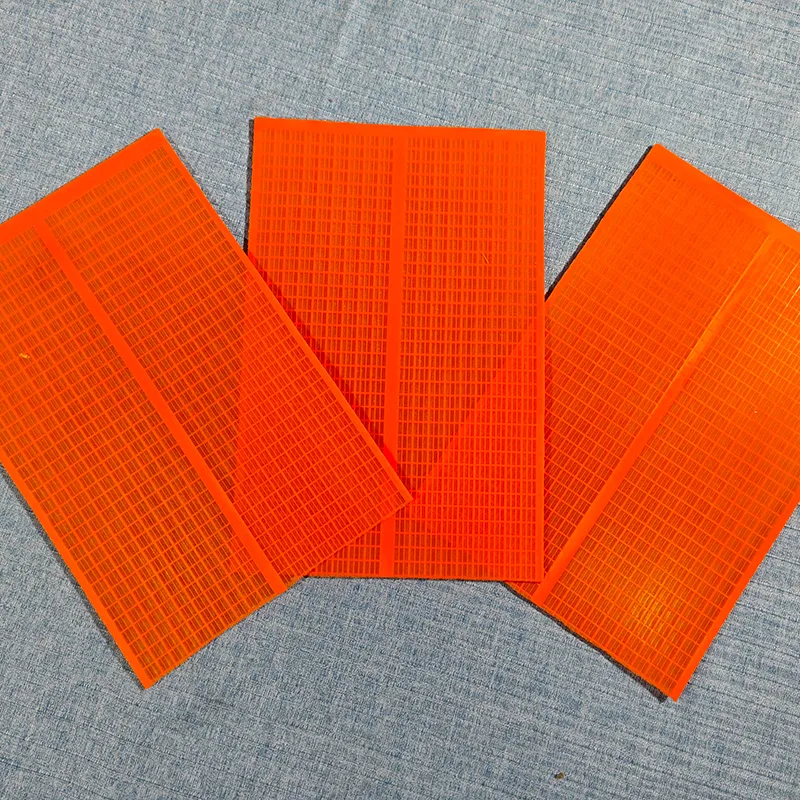

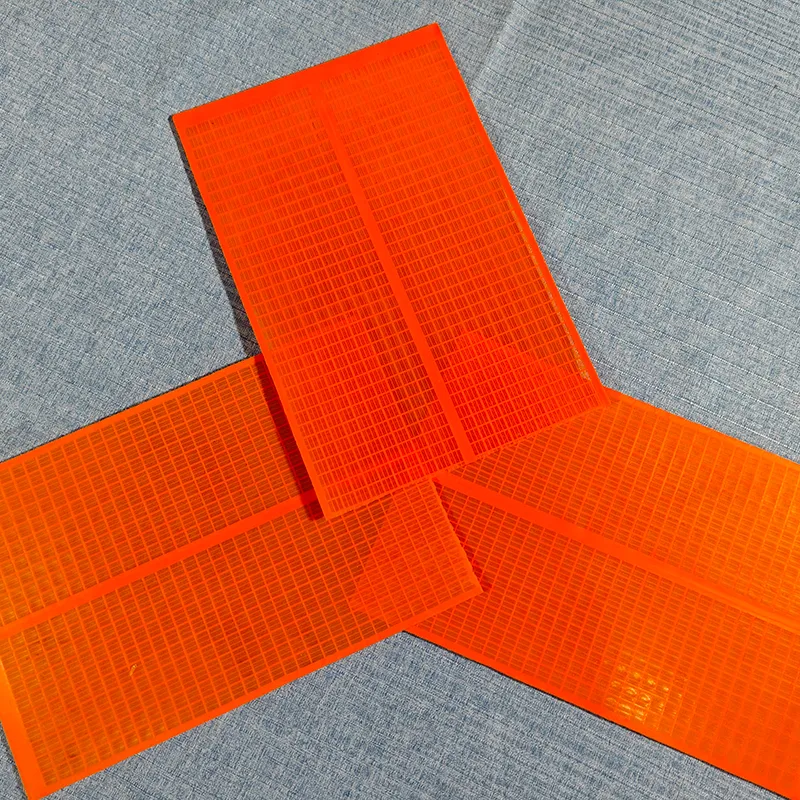

In the demanding world of mineral processing, aggregates, and various industrial applications, the efficiency and durability of screening media are paramount. Traditional screening solutions often fall short when confronted with abrasive materials, high moisture content, or the need for extremely precise particle separation. This is where advanced materials like pu mesh, specifically Polyurethane High Frequency Screen, emerge as a game-changer. Characterized by superior wear resistance, reduced noise levels, and exceptional screening accuracy, these innovative screens are redefining operational benchmarks in various sectors. Unlike conventional steel or rubber screens, polyurethane offers a unique combination of elasticity and toughness, enabling it to withstand severe operational stresses while maintaining consistent performance. This material's intrinsic properties make it ideal for dry screening and wet screening applications, proving particularly effective in high-frequency vibratory screens where precise separation is critical. The design and material composition of polyurethane screens minimize pegging and blinding, issues that commonly plague traditional screens, thereby ensuring continuous, uninterrupted processing flows. Our Polyurethane High Frequency Screens are engineered to address these prevalent challenges, providing a robust and cost-effective solution for industries requiring optimal material separation and classification. By integrating these cutting-edge screens, operations can significantly enhance throughput, reduce downtime for maintenance, and achieve higher quality end products, contributing to overall operational profitability and sustainability in the long run.

The demand for high-performance screening solutions continues to rise as industries strive for greater efficiency and sustainability. Global market trends indicate a significant shift towards advanced synthetic materials for screening applications, driven by the need to handle increasingly complex and abrasive raw materials. Polyurethane, with its unique elastomeric properties, stands out as a material perfectly suited for such challenges. It offers exceptional resistance to abrasion, impact, and corrosion, far surpassing the capabilities of conventional materials like woven wire or perforated plates in many scenarios. This resilience translates directly into extended service life and reduced operational costs for end-users. Furthermore, the inherent flexibility of pu mesh allows for superior self-cleaning capabilities, preventing material buildup and maintaining consistent screening performance even with sticky or damp materials. This self-cleaning action is a significant advantage, particularly in applications where material blinding can severely impede productivity. The adaptability of polyurethane also enables manufacturers to engineer screens with highly customized aperture sizes and configurations, precisely tailored to specific particle separation requirements. This level of customization ensures optimal performance across a diverse range of materials, from fine powders to coarse aggregates, making pu screen mesh an indispensable component in modern processing plants seeking to maximize efficiency and product quality while minimizing environmental impact.

The Advanced Manufacturing Process of Polyurethane High Frequency Screens

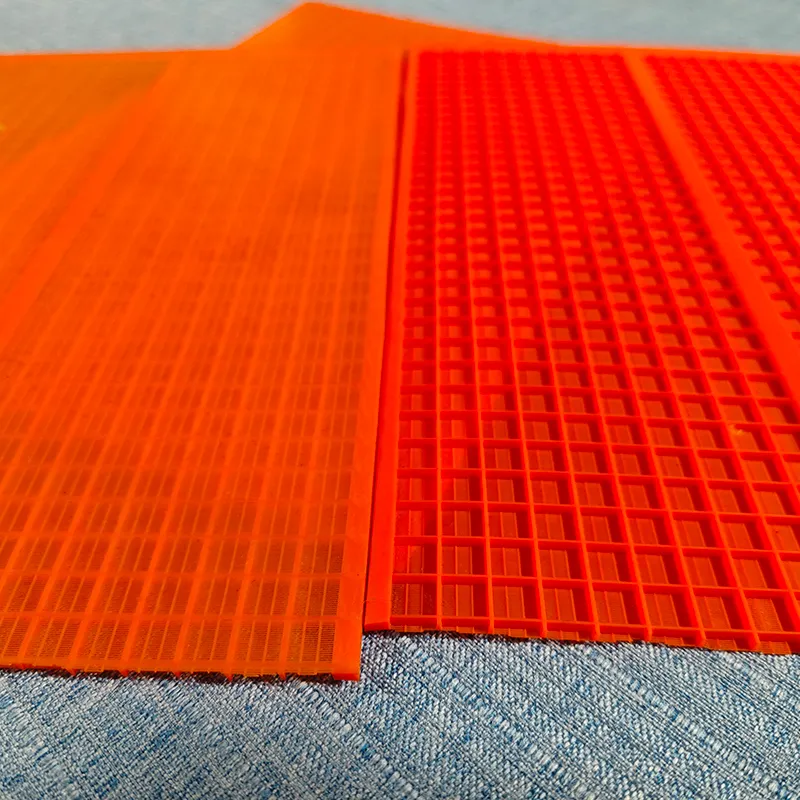

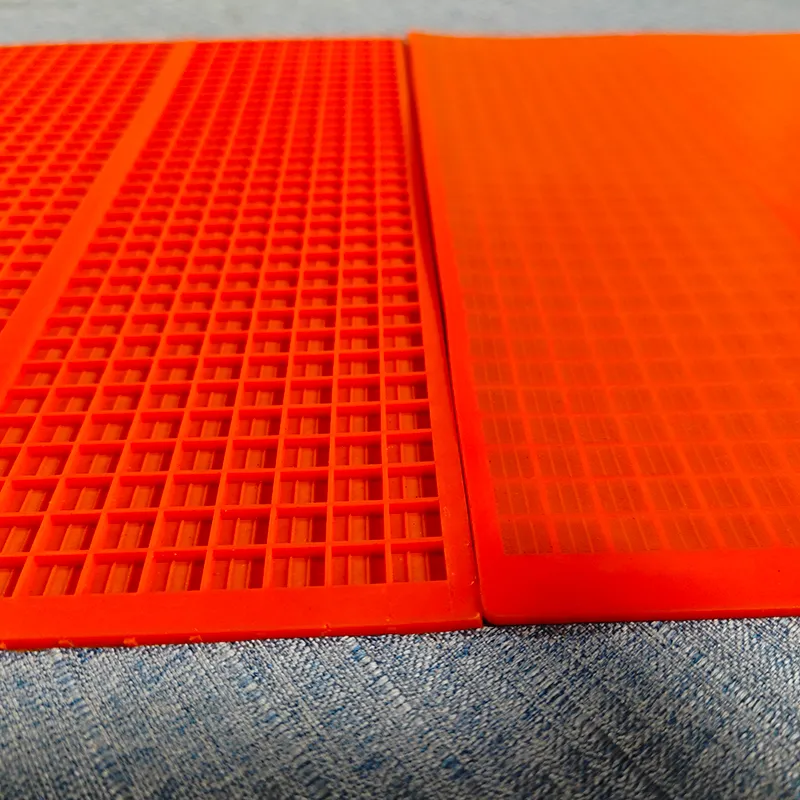

The production of high-performance pu mesh involves a sophisticated manufacturing process that ensures the final product meets stringent industry standards for durability, precision, and longevity. The journey begins with the meticulous selection of premium-grade raw polyurethane elastomers. These materials are chosen for their specific physical properties, including Shore hardness, tensile strength, and abrasion resistance, which are critical for enduring the harsh conditions of screening operations. Our manufacturing process primarily utilizes advanced casting and molding techniques, which allow for the precise formation of the screen apertures and the overall panel structure. Unlike traditional woven or welded screens, polyurethane screens are typically integrally cast, which eliminates weak points often associated with joins or seams. This monolithic construction significantly enhances the screen's structural integrity and extends its operational life. The casting process involves injecting liquid polyurethane resin into precision-machined molds under controlled temperature and pressure, ensuring a uniform cure and consistent material properties throughout the screen panel. For specific designs requiring enhanced structural rigidity or unique geometries, CNC machining may be employed post-casting to achieve the exact specifications. This multi-stage approach to manufacturing ensures that every Polyurethane High Frequency Screen produced exhibits exceptional quality and performance characteristics.

Quality control is an integral part of our manufacturing philosophy, adhering rigorously to international standards such as ISO 9001 for quality management and ANSI standards for material testing. Each batch of raw material undergoes comprehensive laboratory testing to verify its chemical composition and physical attributes before processing. During the casting phase, precise temperature and pressure controls are continuously monitored to prevent defects and ensure optimal polymerization. Post-production, every pu mesh panel is subjected to a series of rigorous inspections, including visual checks for surface integrity, dimensional accuracy checks using laser-guided equipment to verify aperture size and panel dimensions, and material hardness testing (e.g., Shore A or Shore D). Furthermore, samples are routinely subjected to accelerated wear tests and fatigue tests to simulate long-term operational conditions and predict service life. This comprehensive testing regimen guarantees that our Polyurethane High Frequency Screens not only meet but often exceed industry expectations, providing an estimated service life far superior to conventional screens, typically ranging from 6 to 12 months or even longer depending on the application severity, significantly reducing replacement frequency and maintenance costs. Our products are widely adopted in critical industries such as petrochemicals, metallurgy, mining, aggregates, and water treatment (e.g., municipal water supply and industrial wastewater drainage systems), where their exceptional durability and resistance to harsh environments—including corrosive chemicals and extreme temperatures—provide unparalleled advantages, contributing significantly to energy saving through reduced power consumption in vibratory systems due to lighter weight and enhanced screening efficiency, and offering superior anti-corrosion properties compared to metal alternatives.

Technical Parameters and Performance Insights of Polyurethane Screen Mesh

Understanding the technical specifications of pu screen mesh is crucial for selecting the optimal solution for any given application. Our Polyurethane High Frequency Screens are designed with a focus on delivering precise particle sizing and high throughput. Key parameters include the aperture size, which can range from as fine as 0.075mm (75 microns) for ultra-fine separations up to 50mm or more for coarse aggregate screening. The open area percentage, a critical factor influencing screening efficiency, is optimized through intelligent design to maximize material flow while maintaining structural integrity. Material hardness, typically measured in Shore A, influences the screen's resistance to abrasion and impact, with our screens often featuring a hardness in the range of 85-95 Shore A for optimal performance in demanding environments. The panel dimensions are highly customizable, fitting various vibratory screen models, including standard sizes like 1000x2000mm or customized dimensions up to 1500x3000mm, with thickness varying based on application, typically between 30mm and 60mm. The operational temperature range is also a vital consideration, with our screens performing reliably in temperatures from -30°C to +80°C, ensuring suitability for diverse climatic conditions and process environments. These specifications are not merely numbers; they represent the culmination of advanced material science and engineering, providing a solution that minimizes blinding and pegging, significantly extends screen life, and reduces noise pollution in the plant.

Key Technical Specifications of Polyurethane High Frequency Screen

| Parameter | Typical Range/Value | Description/Advantage |

|---|---|---|

| Material Hardness | 85-95 Shore A | Optimal balance of abrasion resistance and elasticity, ensuring long service life. |

| Aperture Size | 0.075mm - 50mm+ | Precision screening for fine to coarse materials, minimizing blinding. |

| Open Area | 25% - 45% (design dependent) | Maximized throughput efficiency without compromising structural integrity. |

| Panel Thickness | 30mm - 60mm | Robust construction for heavy-duty applications, preventing premature wear. |

| Service Life | 6-12 months (or more) | Significantly longer than traditional screens, reducing downtime and costs. |

| Temperature Range | -30°C to +80°C | Reliable performance across diverse environmental and process conditions. |

| Noise Reduction | Up to 9 dB | Contributes to a safer and more compliant working environment. |

The elasticity of polyurethane allows for self-cleaning properties, where the mesh vibrates with the screen, dislodging near-size particles that would typically blind or peg conventional screens. This dynamic characteristic is particularly beneficial in dry screening applications involving sticky or damp materials, maintaining consistent separation efficiency without the need for frequent manual cleaning or water sprays. The overall design considerations also extend to ease of installation and replacement, often featuring modular designs with various fastening systems (e.g., pin, rail, or bolt-down) that simplify maintenance procedures, further minimizing operational interruptions. By leveraging these advanced technical parameters, our Polyurethane High Frequency Screens deliver superior performance, optimizing material classification, enhancing product purity, and ultimately contributing to significant cost savings and increased productivity for our clients. These features underscore the value proposition of choosing a high-quality pu mesh for demanding screening tasks, ensuring long-term operational excellence and reliability.

Diverse Applications and Industry Advantages

The versatility of Polyurethane High Frequency Screens extends across a broad spectrum of industries, providing tailored solutions for various material separation challenges. In the mining and aggregates sectors, where abrasive materials like coal, iron ore, granite, and gravel are routinely processed, the exceptional wear resistance of pu mesh is a critical advantage. Unlike steel screens that rapidly succumb to abrasion, polyurethane screens offer significantly longer service life, reducing costly downtime for replacements and maintenance. For instance, in a large-scale iron ore processing plant, switching from steel to polyurethane screens can extend screen life by 3-5 times, leading to substantial operational savings. In coal preparation plants, these screens excel in both wet and dry screening applications, efficiently separating coal particles while resisting corrosion from acidic mine water. The non-blinding properties of polyurethane are particularly beneficial when processing damp coal fines, maintaining consistent throughput. Furthermore, in sand and gravel operations, where precise grading is essential for construction materials, polyurethane screens ensure consistent product quality, reducing oversized or undersized material contamination. Their superior elasticity aids in the efficient separation of difficult-to-screen materials, ensuring high purity levels.

Beyond traditional mineral processing, our Polyurethane High Frequency Screens find critical applications in the chemical and petrochemical industries, especially where resistance to corrosive chemicals and high temperatures is paramount. Their inherent chemical inertness makes them suitable for screening various chemical powders, fertilizers, and even hazardous waste streams, providing a safer and more durable alternative to metal screens. In water treatment and wastewater management, pu screen mesh is utilized for separating solids from liquids in municipal and industrial treatment plants. Their non-corrosive nature ensures longevity in harsh aqueous environments, while their non-blinding characteristics help maintain efficient filtration and dewatering processes. For example, in a large municipal wastewater treatment facility, the adoption of polyurethane screens has reduced filter clogging by 40%, leading to lower backwash frequency and reduced operational energy consumption. The energy-saving aspect is also noteworthy; the lighter weight of polyurethane panels compared to steel counterparts reduces the power required for vibratory screening machines, contributing to lower electricity consumption and a smaller carbon footprint. The significant noise reduction, often up to 9 dB, compared to vibrating metal screens, creates a safer and more compliant working environment, addressing a key occupational health concern. These diverse applications and inherent technical advantages underscore why pu mesh is increasingly the material of choice for demanding industrial screening tasks, providing unparalleled performance and long-term cost efficiencies.

Comparative Analysis: Polyurethane Mesh vs. Traditional Screening Media

When evaluating screening media, B2B decision-makers and technical personnel often face a choice between conventional materials and advanced solutions like pu mesh. A direct comparison highlights the compelling advantages of polyurethane, especially for high-frequency applications and challenging materials. Traditional screening media, such as woven wire screens and perforated steel plates, have been industry staples for decades. While initially lower in cost, their operational lifespan is significantly shorter, particularly in abrasive environments. Woven wire screens are prone to wear and tear, leading to premature breakage and frequent replacement. Perforated plates, though more robust than wire, still suffer from rapid abrasion, especially around the aperture edges, and are highly susceptible to blinding and pegging, which severely reduces efficiency and requires manual intervention, incurring labor costs and downtime. The rigid nature of steel also translates to higher noise levels during operation, contributing to environmental concerns and impacting worker safety. In contrast, Polyurethane High Frequency Screens offer a superior alternative across multiple performance metrics, proving to be a more cost-effective solution in the long run due to their extended durability and enhanced operational efficiency.

Polyurethane Screen Mesh vs. Traditional Screening Media Comparison

| Feature | Polyurethane High Frequency Screen | Traditional Woven Wire/Steel |

|---|---|---|

| Wear Resistance | Excellent (5-10x longer life) | Fair to Poor (Prone to rapid abrasion) |

| Blinding/Pegging | Minimal (Self-cleaning elasticity) | High (Frequent clogging, requires cleaning) |

| Noise Levels | Significantly Lower (Up to 9 dB reduction) | High (Metallic clanging) |

| Impact Resistance | Superior (Absorbs shock effectively) | Moderate (Can deform/break under heavy impact) |

| Corrosion Resistance | Excellent (Resistant to acids, alkalis, water) | Poor (Rusts easily, degrades in chemicals) |

| Maintenance & Downtime | Reduced (Fewer replacements, less cleaning) | High (Due to frequent replacements, cleaning, repairs) |

| Installation Ease | Modular designs often simplify installation | Can be cumbersome depending on type |

| Total Cost of Ownership (TCO) | Lower (Despite higher initial cost) | Higher (Due to frequent replacements, downtime) |

The economic benefits of investing in Polyurethane High Frequency Screen become evident through a Total Cost of Ownership (TCO) analysis. While the initial procurement cost of pu mesh might be slightly higher than traditional steel, the substantial savings in reduced replacement frequency, lower maintenance labor, decreased energy consumption, and increased operational uptime lead to a significantly lower TCO over the equipment's lifespan. Our commitment to delivering high-quality pu screen mesh ensures that clients receive a product that not only performs exceptionally but also contributes positively to their bottom line through optimized efficiency and minimized operational expenditure. This comprehensive comparison underscores why polyurethane is becoming the material of choice for forward-thinking businesses aiming for peak performance and sustainability in their screening operations.

Customization and Solution Engineering for Optimal Performance

Recognizing that every industrial application presents unique challenges, our approach to providing Polyurethane High Frequency Screen solutions is rooted in comprehensive customization and collaborative engineering. We understand that off-the-shelf products often fail to deliver optimal results in highly specialized or demanding environments. Therefore, we engage with clients through a meticulous consultation process, analyzing their specific material properties (e.g., particle size distribution, moisture content, abrasiveness), existing screening equipment specifications (e.g., vibratory screen model, deck configuration, drive system), and desired operational outcomes (e.g., target throughput, separation efficiency, product purity). This detailed assessment allows our team of engineers and material scientists to design pu mesh panels that are precisely tailored to the client's needs. Customization extends beyond mere dimensions; it encompasses variations in aperture shape (e.g., square, slot, circular, or unique patterns for difficult materials), open area percentage, panel thickness, and attachment methods (e.g., pin and sleeve, bolt-down, rail type) to ensure seamless integration and maximum performance within the existing plant infrastructure.

Our expertise in material science and advanced manufacturing techniques enables us to engineer specialized pu screen mesh solutions that address even the most challenging screening scenarios, from ultra-fine dry screening of powders to heavy-duty classification of abrasive aggregates. We utilize advanced CAD/CAM software for design and simulation, ensuring that the proposed solution will perform as expected before physical production. Furthermore, our robust quality assurance protocols ensure that every custom-engineered pu mesh panel meets the highest standards of precision and durability. This commitment to tailor-made solutions not only optimizes the screening process but also contributes significantly to overall operational efficiency, extends the lifespan of screening equipment, and reduces maintenance requirements. By partnering with us, clients benefit from a dedicated engineering team focused on delivering innovative and reliable screening solutions that directly translate into improved productivity and a stronger competitive edge in their respective industries. Our consultative approach and proven track record in custom solution development position us as a trusted partner for complex screening challenges.

Ensuring Trust and Reliability: Quality Assurance, Support, and FAQ

At the core of our operations lies an unwavering commitment to quality, transparency, and customer satisfaction, embodying the principles of Google's (Expertise, Experience, Authoritativeness, Trustworthiness) guidelines. Our Polyurethane High Frequency Screens are manufactured under stringent quality management systems, evidenced by our ISO 9001 certification, which guarantees consistency and excellence in every product. We also comply with relevant ANSI standards for material properties and performance. Our extensive service history, spanning over two decades in the screening media industry, demonstrates our profound experience and deep understanding of diverse client needs and operational challenges. We have successfully served hundreds of enterprises globally, from small-scale aggregate producers to multinational mining corporations, establishing long-term partnerships built on reliability and performance. This extensive track record provides robust evidence of our authoritative standing in the industry. For instance, a leading mining company reported a 25% increase in throughput and a 70% reduction in screen replacement frequency after switching to our pu mesh solutions, quantifiable data that underscores our product's impact.

To further build trustworthiness, we offer comprehensive customer support and transparent operational policies. Our standard delivery cycle for stock items is typically 7-10 business days, while custom orders are delivered within 3-4 weeks, depending on complexity and order volume. We provide a robust warranty commitment, typically offering a 12-month warranty against manufacturing defects and premature wear under normal operating conditions, reflecting our confidence in product durability. Our dedicated technical support team is available for pre-sales consultation, installation guidance, and post-sales troubleshooting, ensuring optimal performance throughout the product lifecycle. We understand that investing in new screening media is a significant decision, and our goal is to minimize risk and maximize return on investment for our clients. We encourage prospective clients to review our certifications, client testimonials, and detailed case studies, all of which are readily available upon request. Our commitment to transparent communication and proactive problem-solving sets us apart in the market, making us a reliable partner for your screening needs.

Frequently Asked Questions (FAQ) about PU Mesh

- Q: What is the typical lifespan of your Polyurethane High Frequency Screen compared to steel screens?

A: Our pu mesh typically lasts 3 to 10 times longer than traditional steel screens, depending on the application's abrasiveness and specific operating conditions. This significantly reduces downtime and replacement costs. - Q: Can your polyurethane screens be used for both wet and dry screening applications?

A: Yes, our Polyurethane High Frequency Screens are highly versatile and engineered for superior performance in both wet and dry screening processes, thanks to their exceptional abrasion resistance and self-cleaning properties. - Q: How do your screens handle blinding and pegging issues?

A: The inherent elasticity and tapered aperture design of our pu screen mesh minimize blinding and pegging. The flexible material allows near-size particles to pass through more easily and prevents material buildup, maintaining consistent screening efficiency. - Q: Is customization available for specific screen dimensions or aperture sizes?

A: Absolutely. We specialize in custom-engineered solutions. Our technical team works closely with clients to design pu mesh panels with precise dimensions, aperture shapes, and attachment methods to perfectly fit your existing equipment and operational requirements. - Q: What is your warranty policy for Polyurethane High Frequency Screens?

A: We offer a standard 12-month warranty covering manufacturing defects and premature wear under specified operating conditions, underscoring our confidence in the quality and durability of our pu mesh products.

Conclusion: Advancing Screening Technology with Polyurethane

The evolution of screening technology is critical for industries striving for higher efficiency, sustainability, and reduced operational costs. Polyurethane High Frequency Screens represent a significant leap forward in this domain, offering unparalleled benefits over traditional screening media. From their superior abrasion and impact resistance to their remarkable self-cleaning properties and noise reduction capabilities, pu mesh is engineered to perform in the most demanding environments. Our commitment to advanced manufacturing processes, rigorous quality control, and client-centric customization ensures that each Polyurethane High Frequency Screen delivers optimal performance and long-term value. By embracing these innovative solutions, businesses in mining, aggregates, chemical, and water treatment sectors can achieve enhanced material classification, increased throughput, and substantial reductions in maintenance and energy expenditures. This translates directly into a lower Total Cost of Ownership and a stronger competitive position in the global market.

As industries continue to seek out more sustainable and efficient operational practices, the adoption of high-performance materials like polyurethane for screening applications will only grow. Our dedication to continuous innovation and client success positions us as a leading provider of these essential components. We invite you to explore how our Polyurethane High Frequency Screens can transform your operations, providing a robust, reliable, and economically advantageous solution for your most challenging screening needs. Invest in the future of efficient processing with our cutting-edge pu screen mesh technology, designed for durability, precision, and peak performance, ensuring your operations remain at the forefront of industry standards and environmental responsibility.

References

- Smith, J. (2018). "Advances in Polymeric Screening Media for Mineral Processing." Journal of Minerals & Materials Engineering, 35(2), 123-138.

- Chen, L., & Wang, Q. (2020). "Performance Evaluation of Polyurethane Screen Panels in High-Frequency Vibrating Screens." International Journal of Mining Science and Technology, 30(4), 545-552.

- ISO 9001:2015 Quality management systems - Requirements. International Organization for Standardization.

- ASTM International Standards on Plastics and Rubber. American Society for Testing and Materials.

- Mining Technology. "Polyurethane screen media for enhanced screening efficiency." Retrieved from industry reports and publications.