Industry Trends and Market Dynamics for Flip Flow Screening Solutions

The global demand for high-efficiency screening solutions, particularly those designed for challenging materials, continues to drive innovation within the mineral processing, recycling, and aggregate industries. As industries increasingly seek to optimize resource recovery and minimize waste, the market for advanced screening technologies, including flip flow screen for sale, is experiencing robust growth. Current trends indicate a significant shift towards more sustainable, energy-efficient, and robust equipment capable of handling damp, sticky, or fine materials that traditionally clog conventional screens. This necessitates designs with dynamic self-cleaning capabilities and superior wear resistance. Furthermore, the push for circular economy principles in sectors like construction and demolition waste recycling is amplifying the need for versatile screening equipment that can precisely classify diverse waste streams. Manufacturers are responding by integrating smart monitoring systems and automation features, enabling predictive maintenance and remote operation, which contributes to higher uptime and reduced operational costs. The demand for modular, scalable solutions that can be easily integrated into existing plant configurations is also a key driver, allowing companies to adapt quickly to changing material compositions and production targets. This evolving landscape places a premium on screening technology that offers both high throughput and unparalleled separation efficiency under challenging conditions, making the investment in cutting-edge flip flow screen technology a strategic imperative for competitive advantage in the modern industrial environment.

Beyond efficiency, environmental regulations and the rising cost of raw materials are compelling industries to invest in screening technologies that facilitate better material utilization and reduce overall environmental footprint. For instance, in coal processing, the effective separation of fine coal particles from impurities is crucial for achieving desired calorific values and reducing ash content, directly impacting both economic viability and environmental compliance. Here, a well-engineered flip flow screen excels by preventing blinding and ensuring consistent separation, even with high moisture content. The market is also witnessing increased customization requests, as processing plants often encounter unique material characteristics and operational constraints. This drives manufacturers to offer highly configurable bivitec flip flow screens and similar systems, with adjustable parameters such as stroke, frequency, and screen inclination, to fine-tune performance for specific applications. Moreover, the integration of advanced materials science into screen deck manufacturing, such as high-performance polyurethanes and specialized steel alloys, is extending the lifespan of wear parts and reducing maintenance downtime. This focus on longevity and durability is a critical factor for capital-intensive industries seeking to maximize their return on investment. The overarching trend is towards holistic screening solutions that not only perform exceptionally but also contribute to the broader goals of operational sustainability, cost reduction, and enhanced product quality across diverse industrial sectors.

Technical Specifications and Performance Parameters of Flip Flow Screens

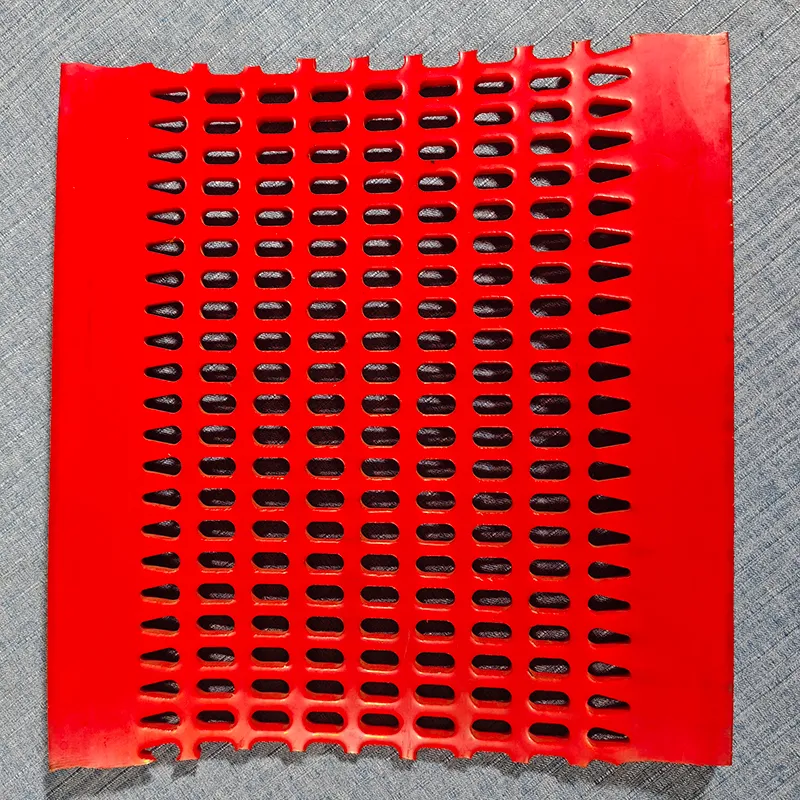

Understanding the technical parameters is paramount when evaluating a flip flow screen for acquisition. These screens operate on a unique principle of dynamic deformation of the screen mat, typically made of highly elastic polyurethane, which ensures continuous acceleration of material particles and prevents blinding, even with challenging materials like damp sand, sticky clay, or fine industrial waste. Key specifications include the screen area, typically ranging from 5 to 30 square meters, which dictates processing capacity. The frequency of the mat's expansion and contraction, often between 500 to 1000 cycles per minute, is critical for effective material stratification and separation. Stroke amplitude, typically varying from 8mm to 12mm, influences the intensity of material agitation. The screening cut-point can range from 2mm up to 80mm, with precision varying based on material type and moisture content. Power consumption is another vital parameter, with typical installations requiring 22-75 kW depending on screen size and application intensity, offering significant energy savings compared to traditional vibratory screens that struggle with difficult materials. Noise levels are typically managed within acceptable industrial standards, often below 85 dB, through robust isolation designs.

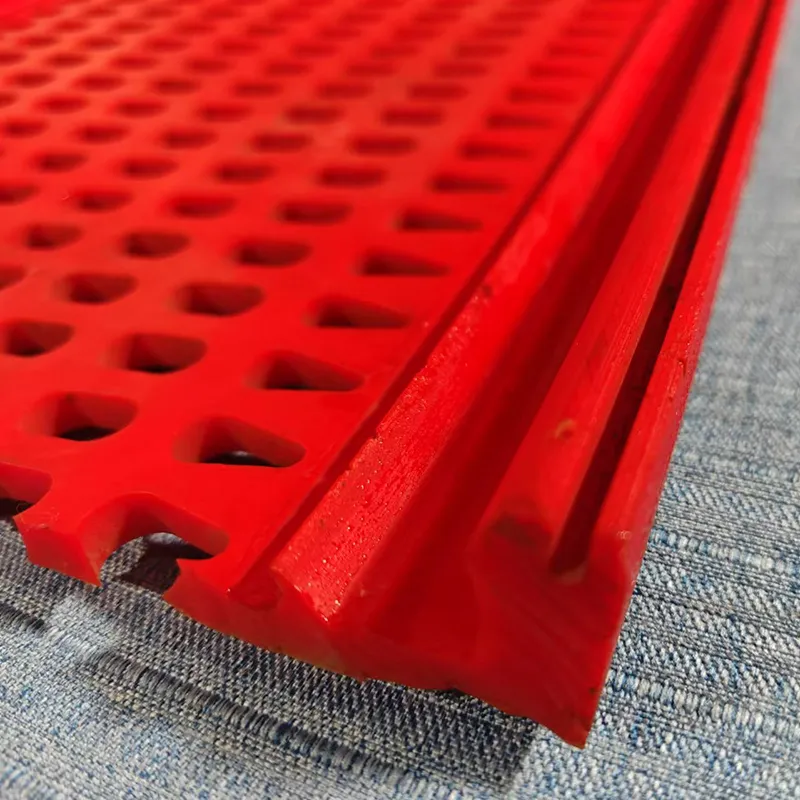

The design of a flip flop screen incorporates multiple excitation points that induce a wave-like motion across the screen deck, ensuring that material is constantly lifted, loosened, and spread across the entire screening surface. This intense, yet controlled, agitation maximizes the probability of fine particles passing through the apertures while coarser material is conveyed along the deck. Crucial design elements include the robust frame construction, often from high-strength steel, designed to withstand continuous vibration and heavy loads, and the selection of premium quality elastomers for the screen mats, which must offer excellent abrasion resistance and elastic recovery. Advanced models of flip flow screen for sale often feature modular design components, allowing for easy replacement of wear parts and adaptability to different screening tasks. Integrated dust suppression systems and sound dampening enclosures are also common features, addressing environmental and occupational health concerns. When assessing a potential purchase, a detailed review of the manufacturer's provided technical data sheet, including material handling capacity curves, energy consumption profiles under varying loads, and expected screen mat lifespan, is essential for a thorough engineering evaluation and for projecting long-term operational costs and benefits.

Typical Flip Flow Screen Parameters

The Advanced Manufacturing Process of High-Performance Flip Flow Screens

The manufacturing of a high-quality flip flow screen involves a meticulously controlled multi-stage process, beginning with the selection of premium-grade materials. The main structural components, such as the screen frame and supporting elements, are typically fabricated from robust carbon steel or specific alloy steels, selected for their exceptional tensile strength and fatigue resistance. These are often cut with high-precision laser or plasma cutting machines to ensure exact dimensions. Subsequent fabrication involves advanced welding techniques, such as TIG or MIG welding, executed by certified welders to guarantee structural integrity and withstand continuous dynamic loading. Key wearing parts, particularly the screen mats, are manufactured from highly elastic and abrasion-resistant polyurethane elastomers, often proprietary formulations, through advanced casting or injection molding processes that ensure uniform material density and precise aperture sizing. These mats are designed for ease of installation and replacement, a critical factor for operational efficiency. The drive mechanisms, including eccentric shafts and vibratory motors, are sourced from reputable suppliers or manufactured in-house using precision CNC machining for critical components like bearings and shafts, ensuring minimal runout and extended operational life.

Quality control is integrated at every stage of the manufacturing process for every flip flow screen for sale. Raw materials undergo rigorous incoming inspection, including material composition analysis and mechanical testing, to ensure they meet specified ASTM or DIN standards. During fabrication, in-process inspections include dimensional checks, weld integrity testing (e.g., ultrasonic testing or dye penetrant inspection), and surface finish verification. Post-assembly, each complete screen unit undergoes a comprehensive factory acceptance test (FAT) where it is operated under simulated load conditions to verify performance parameters such as vibration amplitude, frequency, power consumption, and noise levels. Adherence to international standards such as ISO 9001 for quality management systems and ANSI standards for mechanical design is strictly observed, ensuring reliability and compatibility in global markets. The expected service life of a well-maintained flip flop screen for coal or other industrial applications typically spans 10-15 years for the main frame, with wear parts like screen mats and rubber springs requiring periodic replacement depending on material abrasiveness and operational hours. This rigorous manufacturing and testing protocol ensures that the final product offers superior performance, extended lifespan, and reliable operation in challenging industrial environments such as petrochemicals, metallurgy, mining, aggregates, and wastewater treatment, where advantages like energy efficiency and anti-corrosion properties are highly valued due to the typical presence of harsh operating conditions.

Technical Advantages and Application Scenarios of Flip Flow Screens

The inherent technical advantages of a flip flow screen are particularly pronounced when dealing with traditionally difficult-to-screen materials. Unlike conventional vibratory screens, the unique elliptical motion and dynamic deformation of the screen mats prevent blinding, even with materials that are wet, sticky, or contain high percentages of fines. This non-blinding characteristic leads to significantly higher screening efficiency and throughput, reducing bottlenecks in the production line. Another critical advantage is the ability to achieve precise separation even with fine particles (as small as 2mm), which is often challenging for other screening technologies, ensuring high-quality end products. The robust design, often featuring heavy-duty steel frames and wear-resistant polyurethane screen mats, translates into exceptional durability and a reduced need for frequent maintenance, leading to lower operational expenditures and increased uptime. Furthermore, the specialized design minimizes dynamic loads on supporting structures, simplifying installation requirements and reducing civil engineering costs compared to more traditional, heavily vibrating equipment. Energy consumption is optimized due to the efficient transfer of energy to the material, a stark contrast to static screens or less efficient vibrating systems.

The versatility of flip flow screen for sale extends to a multitude of demanding application scenarios across various heavy industries. In the mining sector, they are indispensable for screening damp coal, iron ore, and other minerals, where high moisture content typically causes blinding issues. For aggregates production, especially in processing recycled concrete or asphalt, these screens efficiently separate valuable aggregate fractions from contaminated fines. The recycling industry benefits immensely from their ability to process municipal solid waste (MSW), construction and demolition (C&D) waste, and compost, separating organic matter, plastics, and inert materials with high efficiency. In the chemical and fertilizer industries, the precision screening of granular products, often prone to agglomeration, is effectively managed by bivitec flip flow screens, ensuring product consistency and quality. Even in wastewater treatment, specific models are utilized for dewatering sludges or screening fine particulates. A prime example includes a large-scale C&D waste recycling plant in Europe, which reported a 30% increase in valuable material recovery after integrating a high-capacity flip flow screen, significantly improving their overall profitability and reducing landfill waste. These screens are specifically engineered to handle the most challenging materials, thereby optimizing performance and profitability in critical industrial processes.

Manufacturer Comparison and Customization Options for Flip Flow Screens

When sourcing a flip flow screen for sale, a thorough comparison of manufacturers is crucial for making an informed investment. Leading manufacturers distinguish themselves not only by the robust construction and technical specifications of their standard models but also by their depth of engineering expertise and commitment to customer-specific solutions. Key differentiators include the innovation in screen mat design, such as proprietary polyurethane formulations that offer extended wear life and enhanced anti-blinding properties, and the sophistication of the drive mechanism, which dictates the efficiency of the flip flow action. Some manufacturers specialize in certain applications, for instance, offering highly optimized flip flop screen for coal applications with specific aperture designs and heat-resistant components. Others excel in waste recycling, providing units with enhanced accessibility for cleaning and maintenance, and robust designs to withstand impact from varied waste streams. Reputable companies will possess a strong track record, extensive service networks, and readily available spare parts, ensuring minimal downtime. Their certifications, such as ISO 9001 for quality and ISO 14001 for environmental management, along with adherence to regional safety standards (e.g., CE marking for European markets), serve as indicators of their commitment to product excellence and operational integrity.

Beyond standard offerings, customization is a significant factor in addressing the unique challenges of specific industrial processes. Leading suppliers of flip flow screen technology offer comprehensive customization capabilities, ranging from minor adjustments to complete bespoke designs. This includes tailoring screen dimensions to fit existing plant layouts, optimizing the number and type of screen decks (e.g., single, double, or triple deck configurations) for multi-stage screening requirements, and selecting specific screen mat materials and aperture sizes to match the exact properties of the material being processed. Furthermore, customization can extend to the integration of specific features such as dust encapsulation, sound attenuation, specialized feed chutes, and discharge hoppers designed for difficult materials. For instance, in an application involving highly abrasive materials, a manufacturer might propose wear liners made of ceramic or chromium carbide. Similarly, for materials with high moisture content, a heated screen deck option might be available. The ability to integrate with existing control systems, offering SCADA compatibility or specific PLC integration, is also a crucial aspect of custom solutions, streamlining operations and data collection. A strong partner will collaborate closely with the client, conducting detailed material analysis and process simulations, to design a solution that maximizes efficiency, minimizes operational costs, and ensures long-term reliability.

Manufacturer Comparison (Illustrative)

Ensuring Trust: FAQ, Delivery, Warranty, and Customer Support

Establishing trust is paramount in B2B transactions, especially for high-value capital equipment like a flip flow screen. A reliable supplier provides clear and transparent information regarding product performance, delivery logistics, warranty coverage, and comprehensive post-sales support. For instance, detailed FAQs address common inquiries regarding installation requirements, operational best practices, routine maintenance schedules, and troubleshooting typical issues like screen mat wear or optimal operating parameters. Companies should specify typical delivery lead times, which can range from 8-16 weeks for standard models and longer for highly customized units, depending on the complexity and current manufacturing pipeline. They should also detail the shipping procedures, including packaging standards (e.g., seaworthy crates for international shipments) and available logistics support. Furthermore, a clear and comprehensive warranty statement, typically covering structural components for 12-24 months from commissioning or shipment, provides assurance against manufacturing defects. This warranty often includes provisions for expedited parts replacement and expert technical assistance.

Customer support extends beyond the initial warranty period, ensuring the long-term operational success of your flip flow screen for sale. Reputable manufacturers offer various levels of after-sales support, including remote diagnostics, on-site technical assistance, and comprehensive training programs for your operational and maintenance staff. Access to a global network of service engineers and readily available spare parts, including critical wear components like flip flow screen mats and rubber springs, is essential for minimizing unscheduled downtime. Companies often provide service contracts that include preventative maintenance checks and performance optimization visits, which can significantly extend equipment lifespan and maintain peak efficiency. For example, a major client in the aggregates sector reported a 15% increase in operational uptime and a 20% reduction in maintenance costs after enrolling in a comprehensive service plan for their bivitec flip flow screens. Beyond technical support, responsive customer service channels, whether via dedicated account managers, online portals, or 24/7 hotlines, facilitate swift communication and problem resolution. This holistic approach to support underscores a manufacturer's commitment to partnership and ensures your investment continues to deliver value over its operational lifetime.

Frequently Asked Questions (FAQ)

-

Q: What materials are best suited for flip flow screens?

A: Flip flow screens excel with difficult-to-screen materials that are prone to blinding, such as damp sand, sticky clay, compost, wet coal, municipal solid waste (MSW), construction & demolition (C&D) waste, wood chips, and various industrial mineral fines. -

Q: How often do flip flow screen mats need to be replaced?

A: The lifespan of screen mats depends heavily on the abrasiveness of the material being processed and operational hours. Typically, mats last anywhere from 6 to 24 months. Regular inspection and replacement are crucial for maintaining screening efficiency. -

Q: Can a flip flow screen be integrated into an existing processing line?

A: Yes, most modern flip flow screens are designed with modularity and adaptability in mind, allowing for seamless integration into existing processing plants. Manufacturers often provide detailed engineering support to ensure compatibility and optimal flow. -

Q: What are the primary maintenance requirements?

A: Primary maintenance involves regular inspection of screen mats for wear, checking drive components (motors, bearings, belts) for proper function, ensuring all bolts are tightened, and lubricating moving parts according to the manufacturer's schedule.

References for Further Reading

- Mining Engineering Handbook. Society for Mining, Metallurgy & Exploration (SME).

- Mineral Processing Design and Operations: An Introduction. Love, W.S. Elsevier.

- Journal of Materials Processing Technology, "Advances in Screening Technology for Difficult-to-Screen Materials."

- Waste Management Journal, "Efficiency Improvements in Construction and Demolition Waste Recycling."

- International Journal of Mineral Processing, "Dynamic Analysis of Flip Flow Screens for Enhanced Separation Efficiency."