Optimizing Separation: The Advanced Wedge Wire Sieve Bend Screen

In industrial solid-liquid separation, efficiency and reliability are paramount. The sieve bend screen stands out as a critical component, engineered to provide high-capacity dewatering, classification, and solids recovery across diverse sectors. MutoScreen's Wedge Wire Sieve Bend Screen embodies precision engineering, offering a robust and highly efficient solution for challenging applications. This article delves into the technical intricacies, manufacturing excellence, diverse applications, and competitive advantages of these essential industrial screens, addressing the needs of technical specifiers and procurement professionals seeking optimized performance and long-term value.

Understanding the Core: Sieve Bend Technology

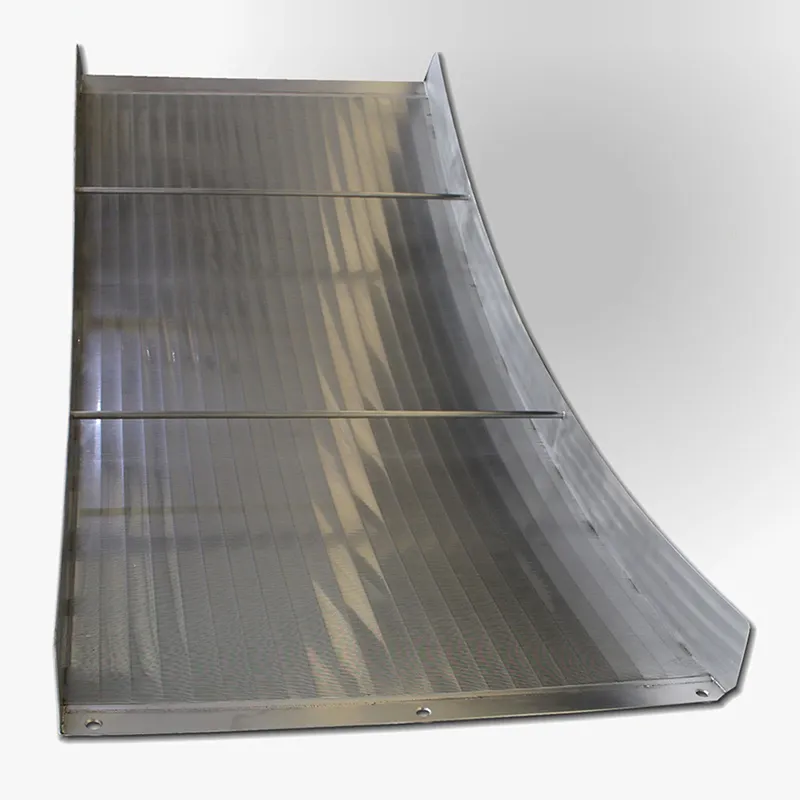

A sieve bend, also known as a static screen or run down screen, utilizes gravity and the Coanda effect for effective separation. It consists of a curved, wedge wire screen surface over which slurry flows. As the slurry travels down the screen, the liquid passes through the precisely sized slots, while solids continue to slide down the screen surface, separating due to their larger particle size and momentum. This passive separation mechanism leads to significant energy savings and reduced operational costs compared to dynamic screening systems. The inherent simplicity and effectiveness of the sieve bend screen design make it a preferred choice for pre-screening, dewatering, and fiber recovery applications where robust, low-maintenance performance is critical. Its ability to handle high flow rates with minimal blinding ensures consistent process efficiency.

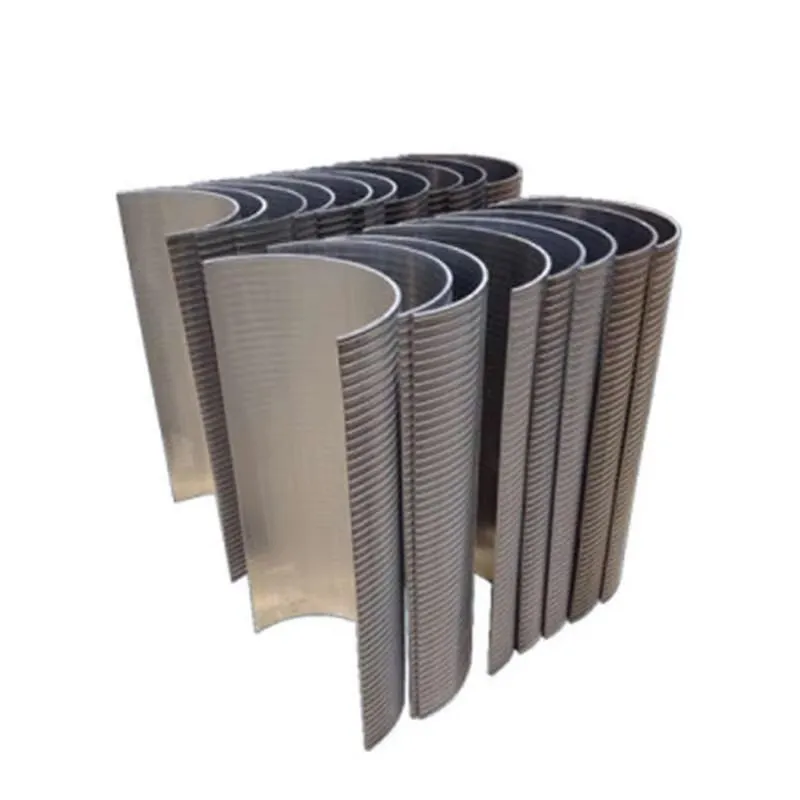

The key to a sieve bend screen's efficiency lies in its profile wires and support rods, typically constructed from high-grade stainless steel. These wires are precisely spaced to create V-shaped slots, which are wider at the bottom to prevent clogging and promote efficient material passage. The curved profile allows for optimal fluid dynamics, maximizing the capture of fine solids while enabling rapid liquid drainage. Understanding the nuanced interplay between the screen's radius, slot size, and wire configuration is fundamental to achieving optimal separation performance for specific industrial challenges.

The MutoScreen Manufacturing Process: Precision and Durability

At MutoScreen, the manufacturing of our Wedge Wire Sieve Bend Screen involves a meticulous process designed to ensure superior performance and longevity. We begin with the selection of premium-grade materials, primarily Stainless Steel 304, 316, and 316L, known for their excellent corrosion resistance and mechanical strength, making them ideal for harsh industrial environments. For highly corrosive or abrasive applications, specialized alloys like Duplex Stainless Steel are utilized to extend the product's lifespan significantly.

Our manufacturing process integrates advanced techniques such as precision welding (often V-shaped continuous slot welding) and state-of-the-art CNC machining. These methods ensure exact slot openings and a uniform screen surface, which are critical for consistent separation efficiency and maximizing the sieve bend screen capacity. Each screen undergoes rigorous quality control, adhering to international standards like ISO 9001 for quality management and ANSI B16.5 for flange dimensions and material specifications, where applicable. Our testing protocols include visual inspection, slot size verification, pressure testing, and material composition analysis, guaranteeing that every unit meets stringent performance criteria and a projected operational lifespan of 5-10 years, depending on application severity and maintenance.

Technical Parameters and Performance Metrics

Optimizing the performance of a sieve bend screen requires a thorough understanding of its key technical parameters. These specifications directly influence the separation efficiency, throughput, and overall operational viability for specific applications. The slot size, typically ranging from 0.05 mm to 2.0 mm, is critical for defining the particle separation cut point. Wire and rod dimensions determine the screen's mechanical strength and open area, impacting flow rate and blinding resistance. Below is a table outlining typical specifications for MutoScreen's Wedge Wire Sieve Bend Screens:

| Parameter | Typical Range / Specification |

|---|---|

| Material Grade | SS304, SS316, SS316L, Duplex SS, Other Alloys |

| Slot Opening (mm) | 0.05 mm - 2.0 mm (Customizable) |

| Profile Wire Size (mm) | 1.0 mm x 2.0 mm to 3.0 mm x 6.0 mm |

| Support Rod Size (mm) | 3.0 mm x 4.0 mm to 6.0 mm x 8.0 mm |

| Open Area (%) | 20% - 40% (depending on slot/wire config) |

| Radius of Bend | Typically 45°, 60°, 120°, 300° (Customizable) |

| Screen Length/Width | Up to 3000 mm length, 2000 mm width (Customizable) |

The actual sieve bend screen capacity is a function of the flow rate, solids concentration, particle size distribution, and the viscosity of the slurry. For instance, a 1-meter wide sieve bend screen with a 0.5 mm slot can process upwards of 200 m³/hr of dilute slurry, while for thicker slurries or higher solids content, the capacity will adjust accordingly. Proper sieve bend screen design considers these variables to ensure optimal throughput and separation efficiency. Engineers leverage computational fluid dynamics (CFD) modeling to predict and optimize flow patterns, enhancing overall system performance and preventing issues like short-circuiting or premature blinding.

Diverse Applications and Key Advantages

Wedge Wire Sieve Bend Screens are indispensable across a multitude of industries due to their versatility and efficiency. In the wastewater treatment sector, they are extensively used for primary screening, grit removal, and dewatering sludge, contributing to significant energy savings by reducing the load on downstream processes. The pulp and paper industry relies on them for fiber recovery and thickening, ensuring resource optimization and minimizing environmental impact. In mining and mineral processing, these screens excel in classifying ores, dewatering concentrates, and recovering valuable minerals, even in highly abrasive conditions.

Other prominent sectors include food and beverage processing for solid-liquid separation in brewing, fruit juice production, and sugar refining, where hygienic design and ease of cleaning are paramount. The petrochemical industry utilizes them for catalyst recovery and effluent treatment. Key advantages of employing Wedge Wire Sieve Bend Screens include their robust construction ensuring long service life, high open area for maximum flow and minimum blinding, efficient dewatering due to the unique profile wire design, and significant energy savings due to their passive, gravity-driven operation. Their resistance to corrosion, particularly when manufactured from SS316L or Duplex Stainless Steel, further enhances their suitability for aggressive chemical environments, providing a cost-effective and low-maintenance separation solution.

Custom Solutions and Manufacturer Comparison

While standard sieve bend screens cater to many applications, complex industrial processes often demand tailored solutions. MutoScreen excels in providing custom sieve bend screen design and manufacturing, adapting parameters such as curvature radius, slot size, material grade, and frame configuration to precisely meet unique operational requirements. This customization is critical for optimizing separation efficiency for unusual particle sizes, high-viscosity slurries, or specific corrosive environments. Our engineering team works closely with clients to develop solutions that seamlessly integrate into existing systems or form the core of new installations, ensuring peak performance and extended product life.

When comparing manufacturers, several factors differentiate a superior Wedge Wire Sieve Bend Screen supplier. MutoScreen stands out through our unwavering commitment to material quality, precision manufacturing processes (ISO 9001 certified), and rigorous testing protocols that often exceed industry norms. While some manufacturers may offer lower initial costs, this often comes at the expense of material integrity, inconsistent slot sizes, or inferior welding, leading to reduced lifespan and frequent replacements. Our focus on certified materials and advanced welding techniques minimizes downtime and maintenance, offering a demonstrably lower total cost of ownership over the product's operational life. Our extensive experience, spanning over 20 years in industrial filtration, underpins our authoritative position in the market.

Real-World Impact: Application Case Studies

Our Wedge Wire Sieve Bend Screens have consistently delivered exceptional results in challenging industrial environments. For example, a major municipal wastewater treatment plant faced significant issues with dewatering primary sludge, leading to high energy consumption and reduced efficiency of downstream processes. By implementing a custom-designed MutoScreen sieve bend screen with optimized slot openings, the facility achieved a 30% reduction in dewatering time and a 15% decrease in polymer consumption, resulting in substantial operational savings.

In another instance, a leading food processing company required a highly hygienic and efficient solution for separating fruit pulp from juice. Standard screens were prone to clogging and difficult to clean, impacting production cycles. MutoScreen provided a polished 316L Stainless Steel sieve bend screen with specific profile wires that minimized particle adhesion and facilitated rapid, thorough cleaning. This not only improved product quality but also reduced cleaning time by 40%, directly increasing daily production capacity. These cases underscore our product's reliability and our commitment to solving complex industrial challenges through expert engineering and robust solutions, building long-term trust with our clients.

Ensuring Trust and Reliability: MutoScreen's Commitment

At MutoScreen, our commitment to trust and reliability is foundational to our operations. We back our Wedge Wire Sieve Bend Screens with comprehensive quality assurance and robust customer support. Our manufacturing facilities are ISO 9001:2015 certified, affirming our dedication to consistent quality management systems. Each product undergoes stringent testing, including material certification, dimensional verification, and weld integrity checks, ensuring adherence to specifications and industry benchmarks. We pride ourselves on transparent communication regarding our delivery cycles, which typically range from 3-6 weeks depending on customization and order volume, with expedited options available for urgent requirements.

We offer a comprehensive warranty, typically 12-24 months from installation, covering manufacturing defects and material failures, providing our clients with peace of mind. Our dedicated technical support team is available for pre-sales consultation, installation guidance, and post-sales troubleshooting, ensuring optimal performance throughout the product's lifespan. Our long-standing relationships with global partners and a history of successful deployments reinforce our authoritative standing in the industrial filtration market. We provide detailed engineering drawings and performance data, backed by internal testing and, where applicable, third-party validation, enhancing the credibility of our product claims.

Frequently Asked Questions (FAQ)

- Q: How do I determine the correct slot size for my application?

A: The optimal slot size depends on the particle size distribution of the solids to be separated and the desired separation efficiency. Our technical team can assist you in selecting the most appropriate slot size based on your specific slurry characteristics and process goals, often requiring a sample analysis or detailed process data. - Q: What materials are available for sieve bend screens?

A: We primarily use Stainless Steel grades (SS304, SS316, SS316L) due to their excellent corrosion resistance. For highly corrosive or abrasive conditions, Duplex Stainless Steel and other specialized alloys are available upon request to ensure maximum lifespan and performance. - Q: What is the typical lifespan of a Wedge Wire Sieve Bend Screen?

A: The lifespan varies based on the application's abrasiveness, corrosiveness, and operational practices. With proper material selection and maintenance, our screens typically last 5 to 10 years, often significantly longer in less demanding environments. Regular cleaning and inspection can extend service life. - Q: Can MutoScreen provide custom sieve bend screen designs?

A: Absolutely. Customization is a core strength. We can tailor the screen's dimensions, curvature, slot size, wire type, and frame configuration to precisely match your unique process requirements and equipment specifications.

Conclusion

The Wedge Wire Sieve Bend Screen represents a pinnacle of efficient, low-maintenance solid-liquid separation technology. MutoScreen's commitment to precision manufacturing, superior material quality, and comprehensive customer support ensures that our products deliver exceptional performance and value in the most demanding industrial applications. From optimizing sieve bend screen capacity in wastewater treatment to achieving fine classification in mineral processing, our custom-engineered solutions are designed to meet the unique challenges of modern industry, providing reliable, long-lasting separation solutions. Partner with MutoScreen for your industrial filtration needs and experience the difference that expertise and quality make.

References

- Smith, J. (2018). Principles of Solid-Liquid Separation. Academic Press.

- International Organization for Standardization (ISO) official publications on Quality Management Systems.

- American National Standards Institute (ANSI) B16.5 standards for pipe flanges and flanged fittings.

- Jones, R. (2020). Advances in Wastewater Treatment Technologies. Environmental Science & Technology Journal.

- Mining & Mineral Processing: Global Market Trends and Technologies Report. (2022). Industry Analytics.