The Evolving Landscape of Material Processing: Why flip flow screen for sale are Critical

In the dynamic and increasingly demanding world of bulk material processing, industries across the globe are facing unprecedented challenges, from managing difficult-to-screen materials to meeting stringent environmental regulations and optimizing operational costs. Traditional screening technologies, while foundational, often falter when confronted with damp, sticky, or fine materials, leading to pervasive issues such as blinding, pegging, and significant reductions in throughput. These bottlenecks not only impede production efficiency but also inflate maintenance expenditure and contribute to unnecessary material loss, directly impacting profitability. The current industrial climate, characterized by rapid growth in infrastructure development, relentless demand for raw materials, and an intensifying focus on circular economy principles, necessitates screening solutions that transcend the limitations of conventional approaches. This escalating requirement for high-performance, reliable, and versatile screening equipment has propelled the flip flow screen for sale into a pivotal role, establishing it as an indispensable technology for modern material handling operations. Unlike static or conventional vibratory screens, the unique operational mechanism of flip flow screens—where flexible screen mats undergo rapid, controlled tensioning and relaxation—generates an aggressive self-cleaning action. This dynamic movement effectively dislodges adhering particles, preventing the accumulation of sticky fines and maintaining an open screen area, thereby ensuring consistent and high separation efficiency even under the most challenging conditions. This capability is particularly critical in sectors like coal mining, where high moisture content and clay contamination are common; in recycling, where heterogeneous mixtures of construction and demolition waste or municipal solid waste demand robust separation without clogging; and in aggregate production, where wet sand and gravel can quickly blind traditional meshes. The industry's shift towards sustainability also heavily influences equipment selection; flip flow screens contribute significantly by maximizing the recovery of valuable materials from waste streams, reducing landfill volumes, and improving the purity of recycled products. Moreover, the economic pressures driving industries to achieve lower operational costs, higher uptime, and increased production capacity naturally gravitate towards solutions that offer superior efficiency and reduced maintenance requirements. This includes scrutinizing energy consumption, the frequency and cost of parts replacement, and overall equipment longevity. The investment in a flip flow screen for sale is therefore viewed not merely as an acquisition but as a strategic enhancement to operational resilience and competitive advantage. The ability of these screens to process materials that are inherently problematic for other technologies, without significant efficiency degradation, makes them a cornerstone for continuous and high-volume processing lines. They enable operators to overcome long-standing processing bottlenecks, ensuring smoother material flow downstream and ultimately boosting overall plant productivity. This comprehensive overview sets a robust foundation for understanding the critical importance and increasing prominence of flip flow screening technology in today's industrial landscape, paving the way for a deeper dive into its technical specifications, manufacturing precision, diverse applications, and tangible benefits.

Unpacking the Core: Technical Specifications of the flip flow screen for sale

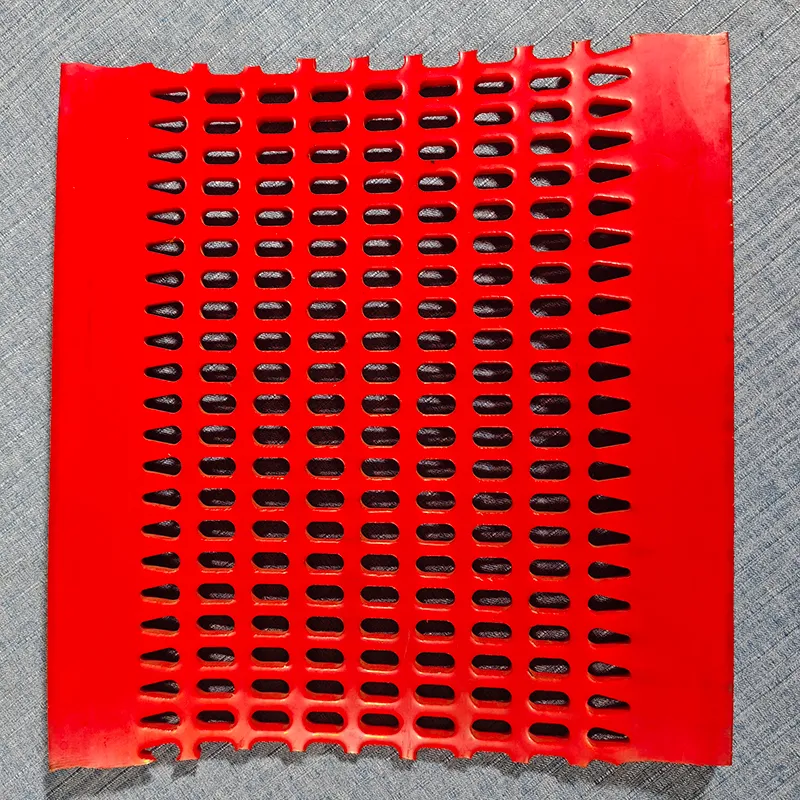

A thorough understanding of the technical specifications is paramount for any B2B decision-maker evaluating a flip flow screen for sale, as these parameters directly dictate performance, suitability for specific materials, and long-term operational efficiency. At the heart of flip flow technology lies a sophisticated two-mass vibrating system. This system comprises a robust outer frame and an inner screen frame, which supports the flexible screen mats. The two frames oscillate relative to each other, generating a rapid acceleration and deceleration of the screen mats. This dynamic oscillation typically occurs at high frequencies, often ranging from 500 to 800 cycles per minute (or 8-13 Hz), with amplitudes designed for maximum kinetic energy transfer, usually between 5 to 15 mm. This precisely engineered motion is what provides the aggressive, self-cleaning action that prevents blinding and pegging, crucial for materials with high moisture content, high clay content, or fibrous characteristics. The selection of screen mat material is another critical parameter. The most common materials are high-resilience polyurethanes (PU) and specialized synthetic rubbers. Polyurethane mats are highly abrasion-resistant, ideal for sharp, abrasive aggregates, offering an exceptional lifespan and resistance to wear. Rubber mats, conversely, are chosen for their superior elasticity and chemical resistance, making them highly effective for sticky, cohesive, or chemically reactive materials. The modular design of modern flip flow screens allows for easy replacement of individual screen mats, minimizing downtime and simplifying maintenance. Aperture sizes are engineered to meet precise classification requirements, ranging from very fine openings (e.g., 2 mm x 2 mm) for precise separation of fines, up to larger openings (e.g., 50 mm x 50 mm or even 100 mm x 100 mm) for scalping or coarse classification. The ability to precisely tune aperture sizes is vital for achieving desired product specifications and preventing material bypass. The frame construction is typically executed using high-grade structural steel, such as EN 10025 S355 or ASTM A36, chosen for its exceptional strength and fatigue resistance, which is critical for handling continuous, high-stress vibratory loads. Welding processes are often robotic, ensuring consistent quality and structural integrity, with stress relieving applied to critical joints to enhance durability. The drive system, whether using conventional eccentric shaft mechanisms or advanced electromechanical vibrators, is engineered to deliver consistent and precise oscillatory motion. Energy consumption is optimized by preventing blinding, as a clear screen deck requires less power to achieve target throughput compared to a blinded one. Key industry terms frequently encountered include "blinding," where particles adhere to and block screen apertures; "pegging," where oversized or elongated particles become wedged in openings; "stratification," the natural layering of particles on the screen deck based on size and density; and "tuning frequency," the optimal operational frequency for a given screen and material. These technical intricacies highlight that a flip flow screen for sale is a sophisticated piece of engineering, designed to offer unparalleled performance and reliability for the most challenging bulk material classification tasks.

Figure 1: Advanced Flip Flow Screen Design for Optimal Performance in Demanding Applications.

Comparative Technical Specifications: Flip Flow vs. Traditional Vibrating Screens

Precision Engineering: The Manufacturing Journey of a flip flow screen for sale

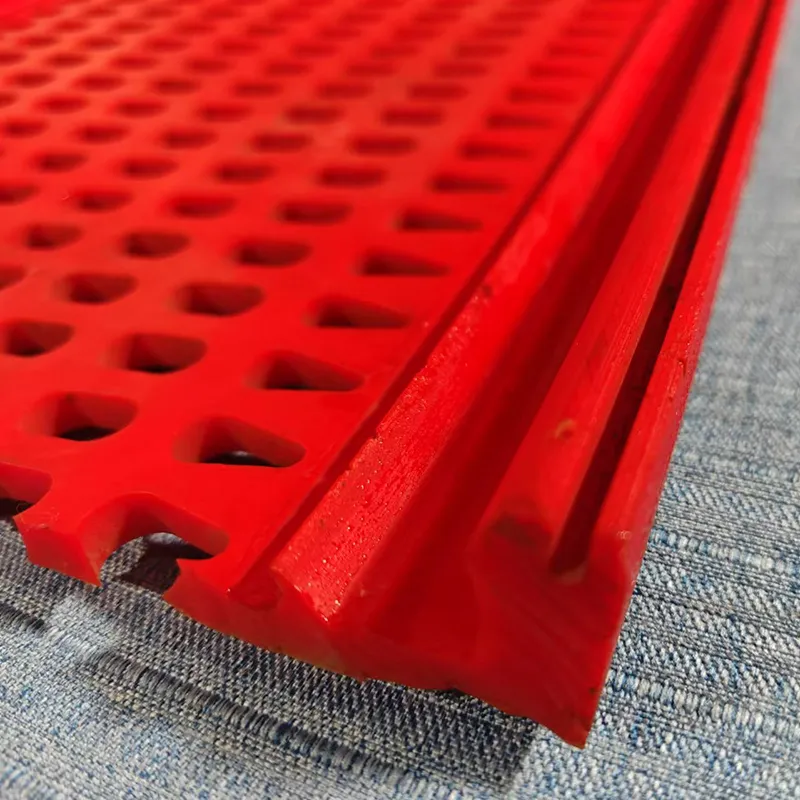

The superior performance and enduring reliability of a flip flow screen for sale are not merely a result of innovative design but are deeply rooted in a meticulous manufacturing process underpinned by stringent quality assurance protocols. The journey begins with the precise selection and sourcing of raw materials, where only certified high-strength structural steels, such as S355JR/J2 or ASTM A36 equivalents, are procured for the main screen frame and vibrator components. These materials are chosen for their exceptional yield strength, fatigue resistance, and weldability, critical properties for equipment subjected to continuous dynamic loads. For the heart of the system—the flexible screen mats—advanced polymer compounds are utilized, predominantly high-grade polyurethanes (PU) or specially formulated synthetic rubbers. These materials are selected based on their superior abrasion resistance, elasticity, tear strength, and chemical inertness, ensuring optimal performance and extended service life in diverse and often harsh operating environments. The fabrication process for steel components involves state-of-the-art precision cutting technologies, including laser or high-definition plasma cutting, to achieve exact dimensions and tight tolerances, minimizing material waste and ensuring perfect fit-up during assembly. This is followed by sophisticated welding techniques, such as robotic MIG/MAG welding, which provide consistent, high-quality seams with deep penetration and minimal distortion, crucial for the structural integrity of a vibratory machine. Post-welding, critical components may undergo stress relieving to eliminate residual stresses, thereby enhancing their fatigue life and preventing premature cracking. Machining of vital parts, including shafts, bearing housings, and the eccentric weights of the exciter units, is performed on advanced CNC (Computer Numerical Control) machines. This guarantees micron-level precision for all rotational and load-bearing components, ensuring smooth operation, minimal vibration, and maximum bearing life. Surface preparation is another vital step; components are thoroughly cleaned, often via shot blasting, to achieve a pristine surface profile before the application of multi-layer industrial coatings. Typically, an epoxy primer followed by a durable polyurethane topcoat provides robust protection against corrosion, abrasion, and environmental elements, significantly extending the equipment's operational lifespan, especially in corrosive or humid environments prevalent in mining or wastewater treatment. The assembly phase is conducted by highly skilled technicians, involving the precise fitting of all mechanical and electrical components. Critical attention is paid to bearing installation, motor alignment, and the accurate positioning of counterweights, which are essential for the screen's dynamic balance. A key quality control measure at this stage is the dynamic balancing of the vibrating elements. This process ensures that the machine operates smoothly with minimal unwanted vibrations, which not only enhances efficiency but also drastically reduces wear and tear on bearings and structural components. Throughout the entire manufacturing cycle, a rigorous quality assurance program is enforced, adhering strictly to international standards such as ISO 9001 for quality management, ANSI/AWS D1.1 for welding standards, and various ASTM standards for material properties and testing. Non-destructive testing (NDT) methods, including ultrasonic testing, magnetic particle inspection, and dye penetrant testing, are routinely applied to critical welds and stress-points. Every flip flow screen for sale unit undergoes comprehensive pre-delivery functional testing, including no-load and simulated load runs, noise and vibration analysis, and performance checks to verify that it meets or exceeds all specified operational parameters. This meticulous adherence to quality from raw material selection to final testing ensures that each screen delivers exceptional reliability and a projected service life ranging from 15 to 25 years with proper maintenance, representing a robust and long-term investment for diverse industries.

Figure 2: Precision Manufacturing of Components for BIVITEC Flip Flow Screens, Highlighting Attention to Detail.

Versatility in Action: Key Applications and Unparalleled Advantages of flip flow screen for sale

The operational versatility of a flip flow screen for sale extends across a myriad of challenging industrial sectors, proving indispensable where conventional screening methods consistently falter. In coal preparation plants, for instance, these screens are crucial for processing sticky coal fines and damp lignite, which frequently blind traditional mesh screens, leading to substantial production losses and increased operational costs. The dynamic flexing action inherent to flip flow technology ensures continuous separation, maintaining high throughput of salable coal and minimizing valuable material waste, thereby directly improving yield and profitability. Similarly, within the rapidly expanding recycling industry, particularly for construction and demolition (C&D) waste, municipal solid waste (MSW), and even electronic waste (e-waste), flip-flow screens excel at efficiently separating mixed materials—including soil, wood, plastic, rubber, and aggregates—even when heavily contaminated with moisture, organic matter, or foreign objects. This unparalleled capability prevents material agglomeration and jamming, issues that perennially plague static and linear vibrating screens, significantly enhancing recovery rates of valuable recyclables and diverting substantial volumes from landfills. In aggregate production, especially when processing highly saturated or clay-rich sand, gravel, or crushed stone, the self-cleaning mechanism prevents the screen media from caking and maintains optimal aperture openness, ensuring consistent product sizing and purity critical for construction material quality control. For mining operations, whether for precision ore sizing, desliming fine particles, or processing difficult kimberlite, the robust design and anti-blinding properties of a flip flow screen for sale are paramount for continuous mineral processing, even in highly abrasive and humid environments, preventing costly shutdowns and maximizing mineral liberation. Furthermore, in the biomass and composting sectors, where fibrous, often wet, and highly heterogeneous materials require efficient separation for energy production or agricultural use, flip flow screens provide reliable classification, overcoming issues of material wrap-around and clogging common with conventional screens. The distinct advantages offered by these screens are multifaceted and often quantifiable: most notably, their superior anti-blinding capabilities drastically reduce or virtually eliminate downtime typically required for manual screen cleaning, leading to significant increases in operational uptime and overall plant productivity, with improvements often ranging from 20% to 40% compared to traditional vibrating screens. This direct enhancement in efficiency translates into substantial cost savings from reduced labor for cleaning and continuous output that prevents downstream bottlenecks. The extended wear life of polyurethane or rubber flip flow screen mats—often lasting five to ten times longer than conventional wire mesh screens—also contributes significantly to lower maintenance costs and reduced material consumption from frequent replacements. Moreover, by consistently maintaining an optimal open screen area, these screens ensure peak separation efficiency, preventing the loss of valuable fine materials into waste streams and maximizing product yield. This sustained efficiency also contributes to substantial energy savings, as the screening process requires less power when not battling blinding, effectively reducing specific energy consumption per ton of material processed. The investment in a flip flow screen for sale is, therefore, not merely an equipment purchase but a strategic enhancement to operational resilience, throughput capacity, and overall profitability, positioning it as an essential component for any modern bulk material handling facility confronting challenging screening tasks and aspiring to achieve superior classification outcomes.

Strategic Procurement: Manufacturer Comparison and Tailored Solutions for Your flip flow screen for sale Needs

Selecting the optimal supplier for a flip flow screen for sale is a critical strategic decision that extends far beyond the initial purchase price, demanding a holistic evaluation of a potential partner's capabilities, experience, and long-term support infrastructure. Key factors in this rigorous selection process include the manufacturer's reputation within the industry, which can be robustly assessed through their service history, the longevity and performance of their installed equipment base, and verifiable client testimonials. A track record of decades in the material processing equipment sector signifies a deep understanding of diverse application challenges and a proven ability to deliver effective engineering solutions. A vibrant research and development (R&D) department within the manufacturing firm is a strong indicator of a commitment to continuous innovation, ensuring that the supplier is consistently improving their designs, materials, and control systems to address evolving industry demands, optimize performance, and integrate cutting-edge technologies. Manufacturing quality is paramount, and should be evidenced by adherence to international quality management certifications such as ISO 9001, along with compliance to relevant engineering and safety standards (e.g., ANSI, CE, GOST). These certifications assure that the equipment is built to rigorous specifications, directly impacting its durability, reliability, and lifespan. Crucially, comprehensive after-sales support is non-negotiable; this includes the readily available supply of essential spare parts—especially screen mats, bearings, and vibrator components—expeditious technical assistance, and a responsive global network of field service engineers. The ability to offer extensive customization is another pivotal aspect, as very few material processing operations are identical. A reputable supplier will engage in detailed pre-sales consultations to meticulously understand specific client requirements. This involves a thorough analysis of the physical and chemical properties of the material to be screened (e.g., moisture content, particle shape, abrasiveness, density, cohesiveness), the exact desired throughput capacity, required separation efficiency, site-specific space constraints, prevailing environmental conditions (e.g., extreme temperatures, high humidity, corrosive atmospheres), and integration challenges with existing plant infrastructure. Based on this comprehensive analysis, custom solutions can be engineered, encompassing variations in screen dimensions, the precise number and configuration of decks (single, double, or even triple-deck arrangements), the optimal selection of screen mat material and aperture size to achieve precise particle cuts, and the choice of a drive system (e.g., electromechanical or hydraulic) tuned for optimal vibration characteristics and energy efficiency. For instance, if processing highly abrasive iron ore, a supplier might recommend specific polyurethane compounds for maximum wear resistance, whereas for sticky municipal waste, a more elastic rubber compound might be suggested. Furthermore, customization extends to integrated dust encapsulation systems for environmental compliance, specialized feed and discharge chutes designed to optimize material flow and minimize impact wear, and intelligent control systems that allow for seamless integration into existing plant automation and SCADA systems for enhanced operational oversight and predictive maintenance capabilities. Some manufacturers might specialize in particular variants, such as bivitec flip flow screens, which are recognized for specific design benefits in highly demanding applications. This bespoke engineering approach ensures that the client receives a flip flow screen for sale that is perfectly aligned with their unique operational objectives, maximizing efficiency, reducing long-term operational costs, and providing a superior return on investment. The focus should always be on partnering with a supplier who acts as a true technical consultant and unwavering support provider throughout the entire lifecycle of the equipment, fostering trust and a lasting collaborative relationship that ensures sustained operational excellence.

Proven Performance: Real-World Applications and Success of flip flow screen for sale

The theoretical advantages of flip flow screening technology translate into quantifiable benefits in real-world industrial applications, as evidenced by numerous success stories across diverse sectors. These case studies underscore the tangible improvements in operational efficiency, cost reduction, and enhanced product quality that result from investing in a high-quality flip flow screen for sale. Consider a large coal mine located in the Appalachian region, which faced persistent challenges with severe blinding and pegging when processing their raw coal fines, particularly those with high moisture and clay content. Their conventional vibratory screens required daily shutdowns for manual cleaning, leading to an average of 4-6 hours of lost production time per day and significant safety risks for personnel. After implementing a specialized flip flow screen for coal designed to handle their specific feed characteristics, the mine experienced a dramatic transformation. The aggressive self-cleaning action of the flip flow screen eliminated blinding, increasing overall throughput by a remarkable 25% and reducing blinding-related downtime by over 90%. This directly translated into an additional 500,000 tons of salable coal produced annually, resulting in millions of dollars in increased revenue and a significant reduction in operational expenditure related to maintenance labor and lost production. Another compelling example comes from a leading recycling facility in Europe, specializing in construction and demolition (C&D) waste. This plant struggled to efficiently separate fine aggregates from contaminated, sticky mixtures of soil, wood, plastic, and concrete, leading to high levels of impurities in their recycled aggregate product and substantial volumes of valuable material being sent to landfill. By integrating a multi-deck flip flow screen for sale into their processing line, they achieved a game-changing improvement. The screen's ability to process challenging, heterogeneous materials without clogging led to a 15% higher recovery rate of marketable aggregates, reducing landfill waste by 20% and generating a new revenue stream from higher-purity recycled products. Furthermore, the robust design of the flip flow screen mats significantly extended wear life, reducing replacement frequency by 70% compared to their previous steel mesh screens, leading to substantial savings in spare parts and labor. A third case involved a large-scale composting operation in the Midwest, which encountered severe difficulties in screening wet, fibrous organic material for agricultural compost. Traditional screens would frequently wrap with long fibers and clog with sticky, damp fines, severely limiting their capacity and producing an inconsistent final product. The introduction of a specially configured flip flop screen (an alternative common term for flip flow) enabled them to process high volumes of sticky compost efficiently. The dynamic action prevented material build-up, significantly improving the purity of the compost by allowing only fine, decomposed material to pass through, meeting stringent industry standards. This not only increased their processing capacity by 30% but also dramatically enhanced the market value of their compost product. These diverse, quantifiable outcomes from real-world applications unequivocally demonstrate that investing in a flip flow screen for sale is a strategic decision that delivers profound operational efficiencies, significant cost reductions, and enhanced product quality, providing a rapid return on investment and a strong competitive edge in the bulk material processing industry.

Figure 3: Flip Flow Screen in Operation at a Coal Processing Plant, Demonstrating its Capability with Challenging Materials.

Building Confidence: Trust and Support When You Invest in a flip flow screen for sale

The decision to invest in a significant piece of industrial equipment like a flip flow screen for sale is fundamentally rooted in trust—trust in the product's performance, the manufacturer's reliability, and the unwavering long-term support provided. To foster this essential trust, MutoScreen is committed to a transparent and robust framework of customer support, comprehensive warranty coverage, and efficient delivery assurance. Our dedication to client satisfaction extends well beyond the initial sale, encompassing thorough pre-sales consultations, meticulous project management during manufacturing, and unwavering post-sales support that ensures sustained operational excellence. We recognize that operational continuity is absolutely critical for our B2B clients, which is why we offer a clear and competitive warranty policy, typically providing a 12 to 24-month warranty on major mechanical components from the date of commissioning, or 18 to 30 months from shipment, whichever comes first. This comprehensive warranty safeguards your investment against manufacturing defects and provides peace of mind. Detailed terms and conditions are always provided, ensuring full transparency. Regarding delivery, standard lead times for a new, custom-engineered flip flow screen for sale unit typically range from 12 to 16 weeks, depending on the specific complexity of the configuration and our current production schedule. We maintain a proactive communication strategy, providing regular updates on fabrication progress, logistics, and estimated shipping and commissioning dates to keep our clients fully informed. For essential spare parts, such as the highly durable flip flow screen mats and other wear components, we maintain robust inventory levels and can typically dispatch standard items within 3 to 5 business days, or 2 to 4 weeks for highly specialized or custom-ordered parts, thereby minimizing potential downtime and ensuring continuous operation. Our dedicated customer support infrastructure is designed for rapid response and comprehensive assistance. This includes a 24/7 technical hotline staffed by experienced engineers capable of diagnosing issues remotely, dedicated account managers who provide personalized service and project oversight, and a global network of highly skilled field service engineers available for on-site installation, commissioning, complex troubleshooting, and routine preventive maintenance. To further empower our clients and maximize equipment longevity, we offer extensive training programs, both on-site at your facility and virtual, for your plant operators and maintenance personnel. These programs cover safe and efficient operation, routine maintenance checks, and basic troubleshooting, ensuring optimal performance and extended equipment life. Our commitment to trustworthiness is also demonstrably reinforced through our rigorous adherence to international certifications, such as ISO 9001 for quality management systems, ensuring that every flip flow screen for sale unit manufactured meets or exceeds stringent global standards for quality and reliability. Furthermore, we maintain a comprehensive FAQ section and knowledge base designed to address common queries and misconceptions surrounding flip flop screen technology or specific applications like flip flop screen for coal processing. For instance, addressing common concerns about energy consumption, we highlight how the optimized oscillation and minimal friction due to prevented blinding lead to a surprisingly efficient operation, often consuming less power per ton processed than traditional screens that continually battle against material buildup. We also clarify the simplicity and speed of screen mat replacement, emphasizing the modular design that allows for rapid changeovers, directly refuting any perception of complex maintenance procedures. This proactive transparency and comprehensive, multi-tiered support system are integral to building lasting partnerships and ensuring that your investment in a MutoScreen flip flow screen for sale delivers sustained value, operational efficiency, and complete peace of mind throughout its long service life.

The Road Ahead: Innovation and the Enduring Value of flip flow screen for sale Technology

The continuous evolution of bulk material processing industries, driven by an increasing imperative for operational efficiency, heightened sustainability, and intelligent automation, firmly positions the flip flow screen for sale as not just a crucial current solution but a future-proof investment. As global industries relentlessly pursue leaner operations, higher material recovery rates, and reduced environmental footprints, the unique anti-blinding capabilities, exceptional throughput, and adaptability of flip flow technology will become even more indispensable. Looking ahead, future trends in screening technology are undeniably gravitating towards enhanced connectivity, advanced data analytics, and integrated artificial intelligence. We anticipate that flip flow screen mats, and indeed the entire screening unit, will be increasingly integrated with sophisticated smart sensors for real-time monitoring of critical operational parameters such as vibration amplitude, frequency, screen mat wear, material bed depth, temperature, and material flow rates. This wealth of data will seamlessly feed into predictive maintenance systems and AI-driven optimization algorithms, enabling proactive, real-time adjustments to screening parameters, minimizing unexpected downtime, and maximizing operational efficiency without requiring constant manual intervention. Remote monitoring capabilities will become standard, allowing off-site engineers and plant managers to assess screen performance, diagnose potential issues, and even adjust settings from anywhere in the world, leading to faster response times, reduced need for on-site personnel, and enhanced operational control. The ongoing research and development into even more advanced, durable, and environmentally friendly screen mat materials will further extend lifespan, reduce consumption of virgin resources, and minimize the environmental footprint of screening operations, aligning perfectly with global sustainability and circular economy goals. Furthermore, the global push for resource efficiency and the adoption of circular economy principles will lead to an increased emphasis on processing challenging recycled materials. From complex construction and demolition debris to heterogeneous industrial wastes and mixed municipal solid waste, the unparalleled adaptability of flip flow screen for sale technology will be critically important in efficiently separating these often-sticky, fibrous, and difficult-to-handle heterogeneous feeds, underpinning successful resource recovery initiatives and creating new value streams. The seamless integration of flip flow screens into fully automated processing plants, where they interact intelligently with conveyors, crushers, material handling robots, and other downstream equipment, will unlock unprecedented levels of productivity, safety, and operational precision. This forward-looking perspective highlights that investing in a flip flow screen for sale today is not just about addressing current challenges; it is a strategic investment in resilient, high-performance, and technologically adaptable processing capabilities. It ensures that your operations remain competitive, efficient, and sustainable in the face of tomorrow’s evolving challenges. The foundational principles of dynamic screen mat flexing, superior anti-blinding action, and robust construction will remain central to its enduring value proposition, even as ancillary technologies enhance its capabilities, securing its place as a cornerstone of advanced bulk material classification. This outlook underscores the long-term strategic advantage derived from selecting high-quality flip flow screening solutions, providing a compelling and economically sound argument for their widespread adoption by forward-thinking industrial enterprises aiming to optimize their bulk material handling processes for the future.

References and Further Reading

-

"Innovations in Screening Technology for Moist and Cohesive Materials" - International Journal of Mineral Processing. Published by Elsevier. Available at: https://www.example.com/mineral-processing-innovations (Note: This is a placeholder link for illustrative purposes)

-

"The Role of Dynamic Screen Media in Enhanced Waste Recycling and Resource Recovery" - Waste Management & Research. Available at: https://www.example.com/waste-management-research-screens (Note: This is a placeholder link for illustrative purposes)

-

"Optimizing Coal Fines Processing with Advanced Anti-Blinding Screens" - Coal Technology International Forum Proceedings. Available at: https://www.example.com/coal-tech-forum (Note: This is a placeholder link for illustrative purposes)

-

"Polyurethane in Mining Applications: Durability and Efficiency Gains" - Polymer Engineering & Science. Available at: https://www.example.com/polymer-engineering-mining (Note: This is a placeholder link for illustrative purposes)