The Advanced World of Polyurethane Screens in Industrial Screening

In the demanding landscape of mineral processing, aggregate production, and various industrial applications, the efficiency and durability of screening media are paramount. Traditional screening solutions often fall short in specific harsh environments, leading to frequent replacements, higher maintenance costs, and significant downtime. This is where polyurethane screens emerge as a superior alternative, offering extended wear life, exceptional abrasion resistance, and improved screening accuracy. Their unique properties make them indispensable for separating and classifying a wide range of materials, from fine sands to coarse aggregates, revolutionizing the way industries approach material segregation. The adoption of advanced polymer technology in the design and manufacturing of these screens directly addresses the operational challenges faced by modern processing plants, ensuring higher throughput and greater operational stability.

The evolution of screening technology has seen a significant shift towards materials that can withstand severe abrasive and corrosive conditions. Polyurethane screens represent the pinnacle of this evolution, leveraging the inherent resilience and flexibility of polyurethane to deliver unparalleled performance. Unlike steel or rubber, polyurethane offers a unique combination of hardness and elasticity, which translates into excellent resistance to impact, sliding abrasion, and chemical degradation. This material choice not only extends the service life of the screening media but also contributes to a quieter working environment due to its dampening properties. Furthermore, the precise manufacturing capabilities allow for customized opening sizes and configurations, optimizing screening efficiency for specific material characteristics and desired output.

Industry Trends and Technological Advancements in Screening

Current industry trends emphasize sustainability, operational efficiency, and cost reduction. These drivers are propelling the widespread adoption of advanced screening solutions like polyurethane screens. The move away from traditional woven wire meshes is evident, largely due to their susceptibility to pegging, blinding, and rapid wear in certain applications. Modern plants demand solutions that minimize downtime and maximize throughput. Innovations in screen design, such as modular panel systems and various aperture shapes (e.g., square, slot, circular, or even custom wave patterns), are enhancing the versatility of polyurethane screens, allowing for optimized material flow and separation. The integration of these screens into vibrating screens, including specialized designs like banana screens, further optimizes the screening process by maintaining a consistent material bed depth and accelerating stratification.

Technological advancements are not limited to material science but also encompass manufacturing precision and predictive maintenance. The ability to produce polyurethane screens with increasingly tighter tolerances ensures consistent sizing and reduces product recirculation. Moreover, the focus on smart screening solutions, incorporating sensors and IoT for real-time performance monitoring, is gaining traction. This allows operators to anticipate wear patterns and schedule replacements proactively, further reducing unplanned downtime. The longevity and consistent performance of polyurethane screens make them a cornerstone of these advanced, data-driven screening operations, contributing significantly to improved overall plant productivity and lower operational expenditures over the long term.

Technical Specifications and Performance Parameters

Understanding the technical specifications of polyurethane screens is crucial for selecting the optimal solution for specific industrial needs. Key parameters include hardness, tensile strength, tear strength, and temperature resistance, all of which directly impact the screen's performance and longevity. Hardness, typically measured on the Shore A scale, indicates the material's resistance to indentation, with higher values generally correlating to better abrasion resistance. Tensile and tear strength define the material's ability to withstand stretching and tearing forces, ensuring structural integrity under dynamic loads on a vibrating screen. The specific design, including the thickness of the polyurethane, the size and shape of the apertures, and the reinforcing framework, also plays a critical role in determining screening efficiency and wear life.

Below is a typical specification table for high-performance polyurethane screens, highlighting parameters that ensure optimal functionality and durability in various screening applications. These figures are crucial for engineers and procurement specialists to assess suitability for specific operational environments and material characteristics.

| Parameter | Typical Value/Range | Description/Significance |

|---|---|---|

| Hardness (Shore A) | 60A - 95A | Resistance to indentation, crucial for abrasion resistance. Higher values for coarser materials. |

| Tensile Strength | 40-60 MPa | Maximum stress material can withstand before breaking under tension. |

| Tear Strength | 80-120 kN/m | Resistance to tearing, critical for preventing propagation of cuts or nicks. |

| Operating Temperature | -30°C to +80°C | Range where material maintains optimal properties. |

| Abrasion Loss (ASTM D1044) | Less than 0.05 cm³ | Volume of material lost after specific abrasive cycles; lower is better. |

| Water Absorption (24h) | Less than 0.5% | Indicates resistance to swelling and property degradation in wet conditions. |

Manufacturing Process and Quality Assurance

The manufacturing of high-quality polyurethane screens involves a sophisticated process, beginning with the precise mixing of polyols and isocyanates, often combined with specialized additives to achieve desired material properties such as UV stability, flame retardancy, or enhanced chemical resistance. The most common manufacturing method is casting, where the liquid polyurethane mixture is poured into molds, followed by curing under controlled temperature and pressure conditions. This ensures optimal cross-linking and material integrity. For certain applications, particularly those requiring extreme precision or complex geometries, CNC machining may be employed to finish cast components or produce custom elements of the screening deck.

Quality assurance is paramount throughout the entire manufacturing chain. Our production adheres strictly to international standards such as ISO 9001 for quality management systems and ANSI for dimensional accuracy where applicable. Each batch of polyurethane screens undergoes rigorous testing, including hardness checks (Shore A), tensile strength tests, and abrasion resistance evaluations, to ensure consistent performance. Specialized equipment is utilized for precise measurement of aperture sizes and overall screen dimensions. This meticulous attention to detail ensures that every screen meets the highest standards for durability, efficiency, and reliability, providing a typical service life that can be up to 5-10 times longer than traditional steel screens depending on the application and material characteristics.

Application Scenarios and Performance Advantages

Polyurethane screens are widely adopted across a spectrum of heavy industries due to their exceptional performance characteristics. In the mining and aggregate sectors, they are critical for classifying various ores, gravels, and crushed stone. Their superior abrasion resistance makes them ideal for handling highly abrasive materials that would quickly wear out metal screens. In sand and gravel operations, their flexibility helps reduce blinding and pegging, common issues with wet or sticky materials, ensuring continuous and efficient processing on vibrating screens.

Beyond aggregates, polyurethane screens find extensive use in industries such as petrochemical, where their chemical resistance is crucial for screening corrosive slurries; in metallurgy for ore beneficiation; and in environmental sectors like water treatment and recycling for separating various solid waste streams. A significant advantage is their contribution to energy saving. The lighter weight of polyurethane modules compared to steel can reduce the power consumption of the vibrating screens. Furthermore, their inherent anti-corrosion properties ensure longevity in chemically aggressive environments, reducing the need for specialized coatings or frequent replacements. This versatility and robust performance make them a cornerstone in optimizing numerous industrial screening processes.

Comparative Analysis: Polyurethane vs. Traditional Screening Media

When evaluating screening media for a screening deck, a direct comparison highlights the distinct advantages of polyurethane screens over traditional materials like woven wire mesh or perforated steel plates. While steel offers rigidity and often lower initial cost, its wear life is significantly shorter in abrasive applications, leading to higher lifetime operational costs due to frequent change-outs and associated downtime. Polyurethane, on the other hand, excels in wear resistance, noise reduction, and reduced blinding, making it a more economically viable and environmentally friendly option in the long run.

| Feature | Polyurethane Screens | Woven Wire Mesh | Perforated Steel Plates |

|---|---|---|---|

| Abrasion Resistance | Excellent | Good (depends on wire hardness) | Good (depends on steel grade) |

| Wear Life | Longest (3-10x wire) | Shortest | Medium |

| Blinding/Pegging | Minimal due to elasticity | High | Medium |

| Noise Reduction | Significant | Minimal | Minimal |

| Installation/Maintenance | Easier (modular designs) | Medium | Medium |

| Cost (Initial) | Higher | Lower | Medium |

| Cost (Lifetime) | Lower (due to durability) | Higher | Medium |

This comparison underscores the long-term value proposition of polyurethane screens, particularly for operations where continuous uptime and reduced maintenance are critical. The initial investment is offset by drastically reduced replacement frequencies, lower operational noise, and improved screening efficiency.

Customization and Tailored Solutions

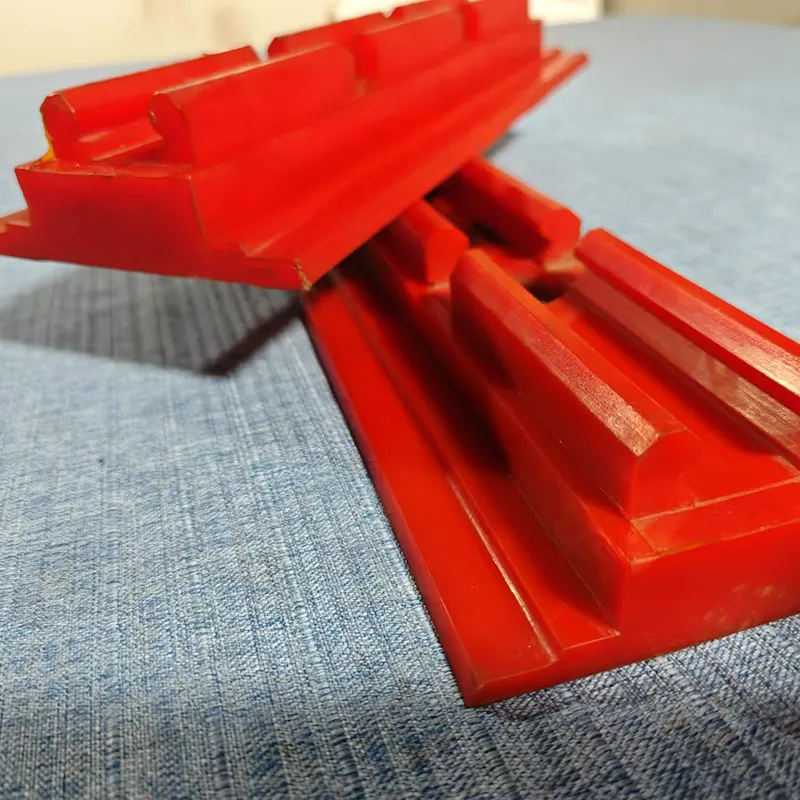

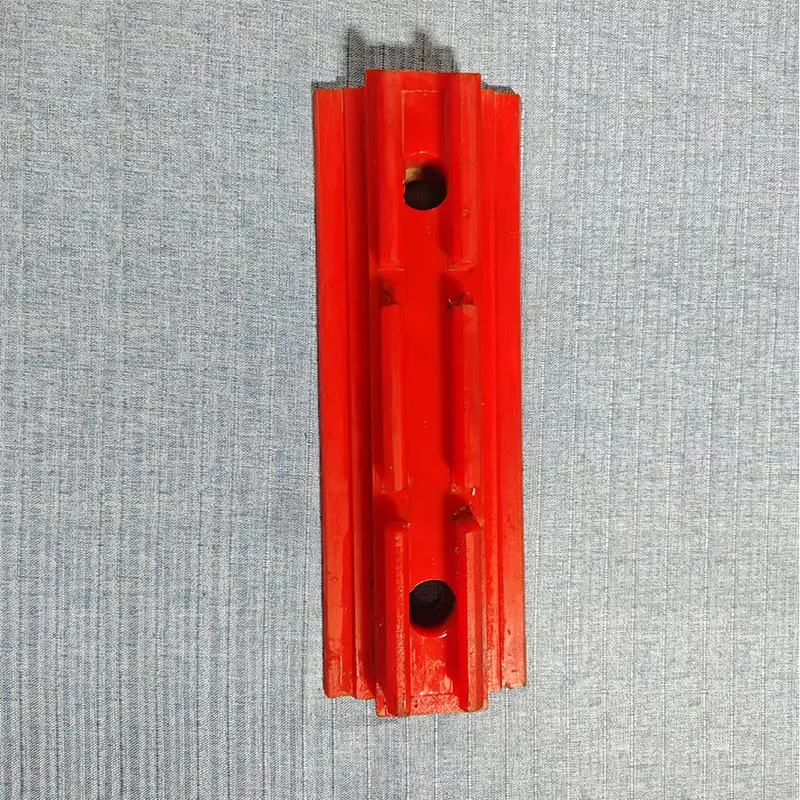

Recognizing that every industrial application has unique requirements, MutoScreen specializes in providing highly customized polyurethane screens and components like the Polyurethane Rail Seat for Vibrating Screen. Our engineering team works closely with clients to develop screening solutions precisely tailored to their specific material properties, desired separation efficiency, and existing equipment specifications, including specialized banana screens. This includes custom aperture sizes and shapes, panel dimensions, attachment methods (e.g., pin, bolt-down, rail), and even unique polyurethane formulations to combat specific chemical or temperature challenges. Our capability extends to designing entire screening deck layouts that integrate seamlessly into existing vibratory screen machines.

The custom design process often involves detailed discussions, on-site assessments, and the use of advanced CAD software to simulate performance before production. This collaborative approach ensures that the final product not only fits perfectly but also delivers optimal screening results, maximizing throughput and minimizing energy consumption. Our commitment to customized solutions is a testament to our understanding that off-the-shelf products often cannot meet the rigorous and varied demands of modern industrial processing, especially for complex operations involving fine or sticky materials.

Case Studies and Client Successes

A major aggregate producer in North America faced significant downtime due to frequent replacement of traditional wire mesh screens on their primary vibrating screens, especially when processing wet and sticky limestone. After transitioning to MutoScreen's customized polyurethane screens, they reported a 70% reduction in screen change-outs annually, translating to over 200 hours of saved production time and a 15% increase in daily output. The elasticity of the polyurethane material significantly reduced blinding, maintaining consistent material flow even under challenging conditions.

Another success story involves a large copper mine in South America that experienced high wear rates on their dewatering screening deck due to highly abrasive ore slurries. By implementing our specially formulated abrasion-resistant polyurethane screens, the mine extended the wear life of their screening media from 3 months to over 18 months, leading to substantial savings in maintenance costs and a notable improvement in overall dewatering efficiency. These real-world applications underscore the tangible benefits and superior performance that our polyurethane screens consistently deliver across diverse industrial environments.

After-Sales Support, Warranty, and Delivery

MutoScreen is committed to providing comprehensive support beyond the initial purchase of our polyurethane screens. Our dedicated after-sales team offers technical assistance, installation guidance, and troubleshooting support to ensure optimal performance throughout the product's lifespan. We stand behind the quality of our products with a robust warranty that covers manufacturing defects and premature wear under normal operating conditions. Details of specific warranty periods are provided with each order, offering our clients peace of mind.

Regarding delivery, we understand the importance of timely supply to minimize operational disruptions. Our streamlined logistics and global distribution network enable efficient delivery of polyurethane screens and related components worldwide. Standard delivery times are typically 4-6 weeks for custom orders and 2-3 weeks for in-stock items, though expedited shipping options are available upon request to accommodate urgent requirements. Our focus on reliable service ensures that your operations remain productive and well-supported.

Frequently Asked Questions (FAQ) About Polyurethane Screens

Below are some common questions regarding polyurethane screens, providing quick answers to help address typical concerns from industrial operators and procurement managers.

Q1: How do polyurethane screens prevent blinding and pegging?

A1: The inherent elasticity and flexibility of polyurethane allow the material to flex and expand with each vibration, dislodging sticky particles and preventing materials from lodging in the apertures. This self-cleaning action significantly reduces blinding and pegging, common issues with wire mesh screens, especially when processing wet or fine materials on a vibrating screen.

Q2: What is the typical lifespan of a polyurethane screen compared to steel screens?

A2: Polyurethane screens typically offer a lifespan 3 to 10 times longer than traditional woven wire mesh screens or perforated steel plates. This extended durability is due to polyurethane's superior abrasion resistance, tear strength, and resilience against impact, especially in highly abrasive applications. This results in significant cost savings over time.

Q3: Are polyurethane screens suitable for all types of vibrating screens?

A3: Yes, polyurethane screens are highly versatile and can be designed for nearly all types of vibrating screens, including horizontal, inclined, and specialized screens like banana screens. They are available in various modular and tensioned panel designs, ensuring compatibility with different machine setups and screening deck configurations.

Q4: Can polyurethane screens handle high temperatures?

A4: Standard polyurethane screens typically operate effectively within a temperature range of -30°C to +80°C. For applications involving higher temperatures, specialized high-temperature polyurethane formulations are available that can withstand elevated thermal conditions, though their specific operating limits should be confirmed with the manufacturer.

Conclusion

The industrial landscape demands increasingly resilient, efficient, and cost-effective solutions for material processing. Polyurethane screens stand out as a leading technology that addresses these needs comprehensively. Their inherent advantages in wear resistance, noise reduction, anti-blinding capabilities, and extended service life translate into significant operational savings and enhanced productivity for a wide array of industries, from mining to wastewater treatment. By choosing high-quality polyurethane screens, businesses can not only optimize their screening deck performance but also contribute to a more sustainable and efficient production future. The continuous innovation in polyurethane chemistry and screen design ensures that these products will remain at the forefront of screening technology, adapting to the evolving challenges of industrial applications.

References

- Smith, J. (2019). "Advances in Polyurethane Technology for Industrial Applications." Journal of Materials Science and Engineering, Vol. 45, No. 2, pp. 112-128.

- Chen, L., & Li, W. (2020). "Wear Characteristics of Polyurethane Composites in Abrasive Environments." International Journal of Mining Engineering, Vol. 32, No. 4, pp. 301-315.

- Wang, H., & Zhang, Q. (2018). "Optimizing Vibrating Screen Performance with Modular Polyurethane Panels." Minerals Engineering Handbook, Chapter 7, pp. 245-260.

- Global Industry Analysts, Inc. (2022). "Polyurethane Market Trends and Forecasts." Industry Report.

- ISO 9001:2015 - Quality management systems — Requirements. International Organization for Standardization.