The Crucial Role of Sieve Bend Screens in Industrial Separation

In industrial solid-liquid separation, efficiency and reliability are paramount. Among the most effective solutions, the sieve bend screen stands out for its high capacity and precise separation capabilities. These innovative devices, often referred to simply as sieve bends, utilize a unique curved screen design to achieve superior dewatering, sizing, and recovery of solids from slurries. This article delves into the technical intricacies, vast applications, and strategic advantages of Wedge Wire Sieve Bend Screens, providing an essential guide for B2B decision-makers seeking optimized processing solutions. We will explore everything from design principles and manufacturing excellence to real-world performance metrics and customization options, ensuring a comprehensive understanding of their critical role across various industries.

The demand for efficient and environmentally sound industrial processes continues to drive innovation in filtration and separation technologies. Current trends highlight a move towards more durable materials, enhanced design for higher throughput, and intelligent systems that minimize operational costs and maintenance. Sieve bend technology aligns perfectly with these trends, offering a passive, energy-efficient solution that delivers consistent performance, even in challenging environments. Understanding the core principles of a sieve bend is the first step toward appreciating its widespread utility and the significant impact it can have on operational efficiency and product quality.

Unpacking the Wedge Wire Sieve Bend Screen Design and Functionality

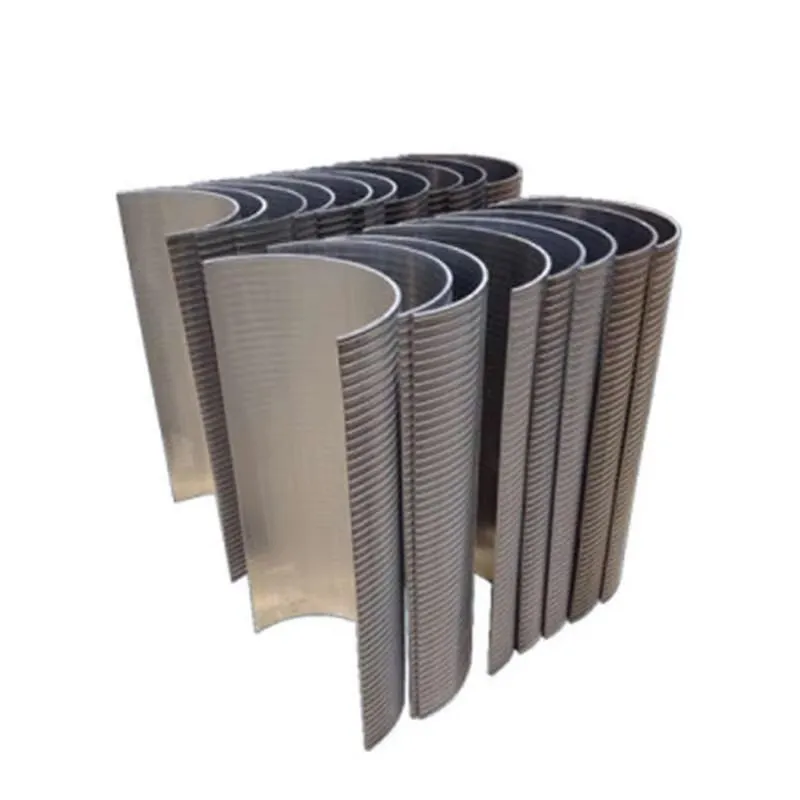

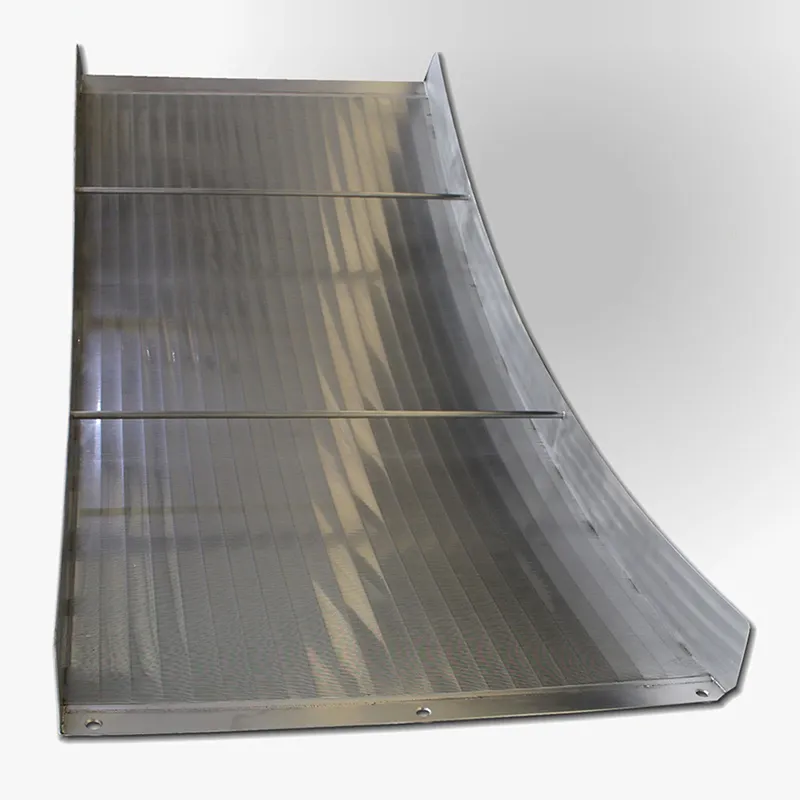

At its core, a sieve bend screen is a curved stationary screen that employs a unique wedge wire profile to achieve efficient separation. The design features a series of parallel V-shaped wires, or wedge wires, that are resistance welded to support rods. This creates a continuous slot opening, which is narrower at the top surface and widens downwards. When a slurry flows tangentially across the curved surface, the liquid passes through the slots while solids are retained and slide down the screen. This "Coanda effect" enhances separation efficiency and prevents blinding, making the sieve bend screen design remarkably effective for high-flow applications.

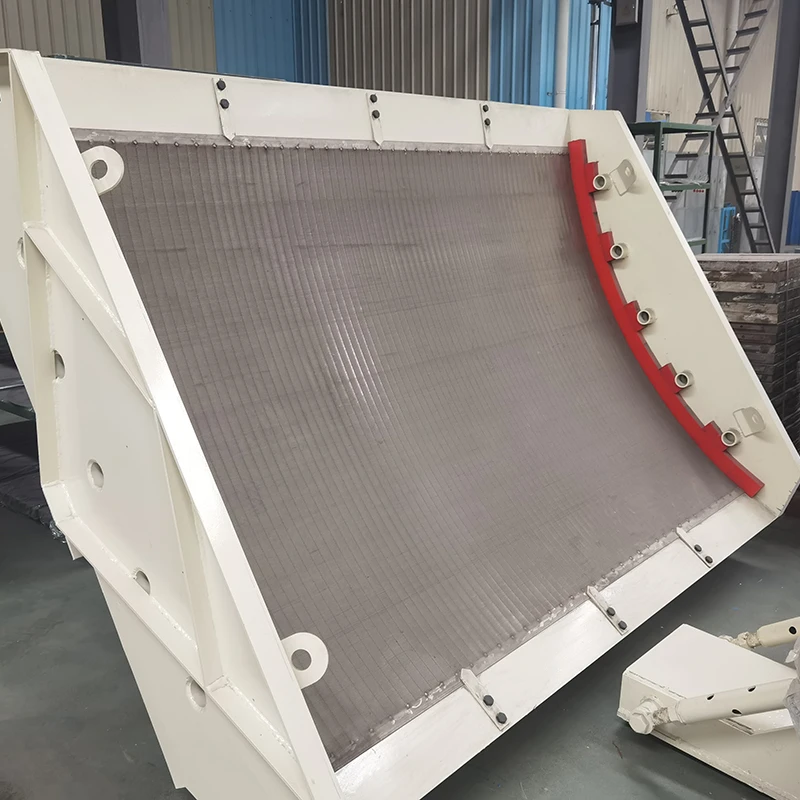

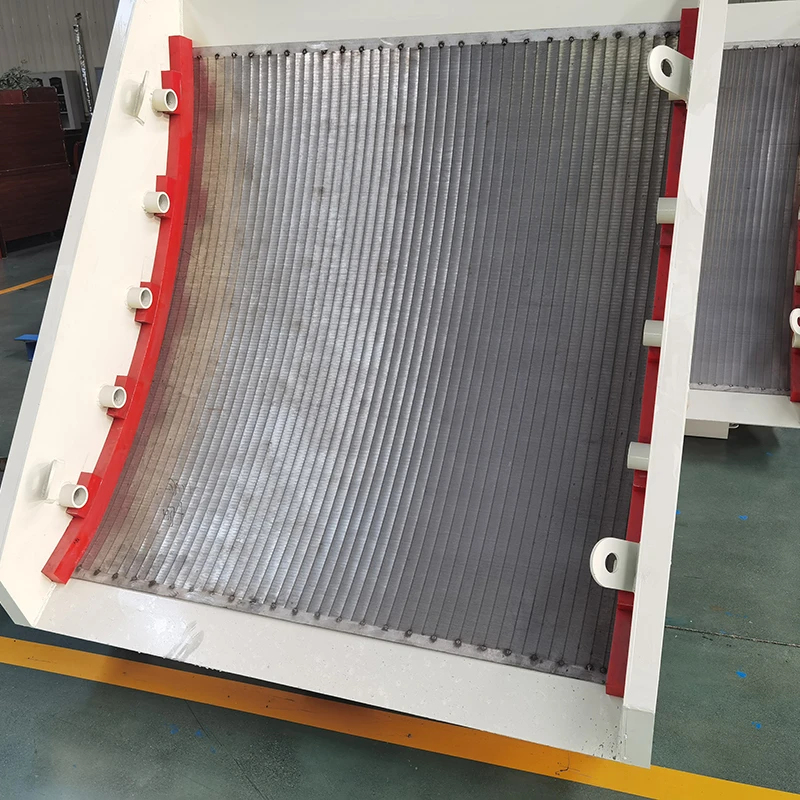

The curvature of the screen, typically ranging from 45 to 60 degrees, plays a vital role in optimizing the separation process. The feed slurry enters a header box and is distributed evenly over the screen’s surface. As the liquid drains through the wedge wire slots, the solids are dewatered and discharged from the bottom lip of the screen. This passive filtration system requires no moving parts, significantly reducing energy consumption and maintenance needs compared to vibrating screens or centrifuges. The inherent simplicity and robust nature of the sieve bend make it an indispensable tool for a wide array of industrial separation challenges, from wastewater treatment to mineral processing.

The Meticulous Manufacturing Process of Wedge Wire Sieve Bend Screens

The manufacturing of high-quality Wedge Wire Sieve Bend Screens involves a sophisticated process designed to ensure precision, durability, and optimal performance. The primary material choice is crucial, with stainless steel grades like 304, 316, and 316L being predominant due to their superior corrosion resistance and strength. For highly corrosive or abrasive environments, duplex stainless steels or specialized alloys may be employed. The manufacturing process typically begins with the selection of high-grade wedge wires and support rods. These are then precisely arranged and joined using resistance welding, a method that creates strong, uniform bonds without external filler materials, ensuring consistent slot openings and structural integrity.

Following the welding, the flat panels undergo a precise bending process to achieve the required curvature, which is critical for the Coanda effect to function optimally. This may involve specialized CNC bending machines to ensure accuracy across various radii and angles. Post-bending, each sieve bend screen is subjected to rigorous quality control measures. This includes visual inspections, slot width verification using precise gauges, and material composition analysis. Compliance with international standards such as ISO 9001 for quality management and ANSI standards for dimensional accuracy is non-negotiable, ensuring product reliability and extended service life, often exceeding 10 years with proper maintenance. This meticulous approach guarantees that each screen can withstand the demanding conditions of industrial use, providing consistent and efficient separation for applications in petrochemicals, metallurgy, and water treatment.

Precision engineering ensures the superior performance of Wedge Wire Sieve Bend Screens.

Key Technical Parameters and Performance Metrics

Understanding the technical parameters is essential for selecting the appropriate sieve bend screen for a specific application. Key specifications include the slot opening, wire profile, material grade, screen dimensions (width, length, radius of curvature), and screen angle. The slot opening, typically ranging from 0.25mm to 3mm, dictates the particle size that can pass through, directly impacting separation efficiency. The wire profile, often triangular (V-shaped), maximizes open area and minimizes blinding. Factors such as the feed slurry's solid concentration, viscosity, and particle size distribution significantly influence the achievable sieve bend screen capacity.

Performance is commonly measured by parameters like throughput rate, solids capture efficiency, and dewatering effectiveness. For instance, a well-designed sieve bend screen can dewater slurries containing high concentrations of solids (e.g., up to 40% solids by weight) and achieve solid capture efficiencies exceeding 90% for particles larger than the slot size. The energy efficiency is a significant advantage, as these screens operate solely on gravity, eliminating the need for motors or complex controls. Below is a table detailing common specifications and performance ranges for typical Wedge Wire Sieve Bend Screens, showcasing their versatility and robust operational capabilities across various industrial demands.

| Parameter | Typical Range/Value | Impact on Performance |

|---|---|---|

| Slot Opening | 0.25 mm to 3.0 mm (0.010" to 0.120") | Determines separation cut point; finer slots for smaller particles. |

| Screen Angle | 45° to 60° (from horizontal) | Influences dewatering rate and solids discharge; higher angles for drier solids. |

| Radius of Curvature | Typically 1.5 to 2.5 times screen width | Affects centrifugal force and liquid separation efficiency. |

| Material | SS304, SS316L, Duplex SS, Hastelloy | Corrosion and abrasion resistance; impacts lifespan. |

| Throughput Capacity (Water) | Up to 150 m³/hr per meter of width (varies by slot size) | Indicates liquid processing volume; critical for high-flow applications. |

| Solids Removal Efficiency | Typically 50% to 90%+ for particles > slot size | Measures effectiveness in removing suspended solids. |

| Pressure Drop | Minimal (gravity-fed system) | Contributes to energy savings; no external power required. |

These specifications allow engineers and procurement specialists to precisely match a sieve bend screen to their operational needs, ensuring optimal performance and cost-effectiveness. The robust construction and simple operational principle contribute to minimal downtime and reduced operating expenses, making them a wise investment for long-term industrial use.

Diverse Application Scenarios and Industry Advantages

Wedge Wire Sieve Bend Screens are exceptionally versatile, finding critical applications across a broad spectrum of industries where efficient solid-liquid separation is required. In the wastewater treatment sector, they are extensively used for primary screening, removing solids from municipal and industrial effluents, protecting downstream equipment like pumps and clarifiers. For food and beverage processing, these screens are invaluable for dewatering fruit pulp, spent grain from breweries, or processing starch, ensuring product purity and reducing waste. The non-blinding nature of the sieve bend design is particularly advantageous in these industries where fouling can be a major issue.

Furthermore, in mineral processing, they are utilized for dewatering various slurries, classifying fine particles, and recovering valuable minerals like coal, iron ore, and sand. Their robust construction allows them to withstand abrasive slurries common in mining operations. The paper and pulp industry benefits from sieve bend screens for fiber recovery and white water clarification. Beyond these, applications extend to chemical processing for catalyst recovery, sugar processing for juice clarification, and agriculture for manure separation. The inherent technical advantages, such as low energy consumption, minimal maintenance due to no moving parts, and superior corrosion resistance when manufactured from appropriate materials like stainless steel, translate directly into significant operational savings and enhanced productivity for businesses.

A sieve bend screen in action, showcasing its robust industrial application.

Industry Trends and Innovations: Beyond the Traditional Sieve Bend

The separation technology landscape is continuously evolving, driven by the need for greater efficiency, sustainability, and adaptability. While the fundamental principles of the sieve bend screen remain effective, advancements are being made in material science, design optimization, and integration into smart systems. There's a growing trend towards modular designs, allowing for easier installation, scaling, and maintenance. Manufacturers are also exploring advanced surface treatments and coatings to further enhance corrosion resistance and reduce fouling in challenging applications, thereby extending the service life of these critical components and minimizing operational interruptions.

Furthermore, the concept of run down screens, which are essentially flat or slightly inclined wedge wire screens, sometimes complements or serves as an alternative in specific separation scenarios. While they lack the inherent self-cleaning advantage of the curved sieve bend, their simpler design makes them suitable for certain low-headroom or preliminary screening applications. The future of separation technology points towards integrating IoT sensors for real-time monitoring of flow rates and solids loading, enabling predictive maintenance and dynamic optimization of the separation process. These innovations promise to further cement the position of the sieve bend as a cornerstone technology in industrial separation, adapting to the ever-increasing demands for precision and resource efficiency.

Why Choose MutoScreen for Your Wedge Wire Sieve Bend Screen Needs

Selecting the right manufacturer for industrial screening solutions is as critical as choosing the technology itself. MutoScreen stands as a leader in the design and production of high-performance Wedge Wire Sieve Bend Screens, backed by years of specialized experience and a commitment to engineering excellence. Unlike many general fabricators, MutoScreen focuses on precision wedge wire products, ensuring unparalleled quality, durability, and performance tailored to specific industrial requirements. Our dedication to superior craftsmanship is evident in every screen we produce, from material selection to the final inspection, adhering strictly to international quality benchmarks like ISO 9001.

Our advantage lies in our deep technical expertise and advanced manufacturing capabilities, allowing for bespoke solutions that perfectly match complex operational parameters. Whether it's a unique slot size, a specialized material for highly corrosive media, or a custom radius for optimal sieve bend screen capacity, MutoScreen offers comprehensive customization services. Our engineers work closely with clients to develop solutions that not only meet but exceed expectations, ensuring maximum efficiency and longevity. We pride ourselves on transparent communication, reliable delivery schedules, and robust post-sales support, building long-term partnerships based on trust and mutual success. This client-centric approach, combined with our technical prowess, distinguishes MutoScreen as the preferred partner for demanding separation challenges.

MutoScreen's commitment to custom engineering for precise sieve bend screen applications.

Ensuring Trust and Reliability: MutoScreen's Commitment to Clients

At MutoScreen, trustworthiness is foundational to every interaction and product we deliver. Our commitment is underpinned by transparent processes, verifiable quality, and unwavering customer support. We adhere to stringent quality management systems, evidenced by our ISO certifications, ensuring that every Wedge Wire Sieve Bend Screen meets the highest international standards for performance and durability. Our extensive service history, spanning several years and serving diverse global clients, reflects our proven reliability in the industrial screening sector. We are proud of our client testimonials and repeat business, which stand as testaments to our consistent delivery of high-quality products and services.

We understand the critical nature of industrial operations, which is why we offer robust support from initial consultation through to post-installation. Our typical delivery cycles are meticulously managed to ensure timely arrival, minimizing potential project delays. Each product comes with a comprehensive warranty, affirming our confidence in its longevity and performance. Should any questions or issues arise, our dedicated customer support team is readily available to provide expert assistance. We also offer comprehensive technical documentation and maintenance guidelines, empowering our clients to maximize the lifespan and efficiency of their sieve bend screen installations.

Frequently Asked Questions (FAQ) about Sieve Bend Screens

Q1: What are the primary benefits of using a sieve bend screen over other separation technologies?

A1: Sieve bend screens offer numerous advantages including low energy consumption (gravity-fed), minimal maintenance due to no moving parts, non-blinding wedge wire design, high throughput capacity, and effective dewatering. They are also highly durable, especially when constructed from corrosion-resistant materials like stainless steel.

Q2: How do I determine the correct slot opening for my application?

A2: The ideal slot opening depends on the desired particle separation size, the nature of the slurry (solids concentration, particle shape), and the required effluent quality. Our engineering team can assist in selecting the optimal slot size based on a detailed analysis of your specific process parameters and target separation efficiency.

Q3: What materials are available for sieve bend screens, and why?

A3: Commonly available materials include Stainless Steel 304, 316, and 316L for general corrosion resistance. For highly aggressive or abrasive environments, Duplex Stainless Steels (e.g., 2205), Hastelloy, or other specialized alloys are used to ensure maximum lifespan and chemical compatibility. The choice of material directly impacts the screen's resistance to corrosion, abrasion, and high temperatures.

Q4: What is the typical lifespan of a Wedge Wire Sieve Bend Screen?

A4: With proper material selection for the application and regular cleaning, a high-quality Wedge Wire Sieve Bend Screen can have a service life exceeding 10 years. Factors such as abrasive solids, chemical aggressiveness, and frequency of backwashing influence longevity. MutoScreen's screens are designed for maximum durability in challenging industrial environments.

Q5: Can MutoScreen provide customized sieve bend screen design solutions?

A5: Absolutely. MutoScreen specializes in custom engineering solutions. We can manufacture sieve bend screens with specific dimensions, radii, angles, slot openings, and material grades to perfectly integrate with your existing systems and meet unique process requirements. Our experienced team works closely with clients to deliver optimal custom designs.

MutoScreen's commitment to supporting client queries on sieve bend screen applications.

Conclusion: The Enduring Value of Sieve Bend Screens

Wedge Wire Sieve Bend Screens represent a highly effective, energy-efficient, and low-maintenance solution for solid-liquid separation across a multitude of industrial applications. Their robust design, coupled with precision manufacturing, ensures reliable performance and an extended operational lifespan. By understanding the intricate details of their design, manufacturing processes, and diverse application benefits, industrial operators can make informed decisions that significantly enhance their process efficiency, reduce operational costs, and contribute to sustainable practices. As industries continue to seek advanced separation solutions, the fundamental efficacy and adaptability of the sieve bend ensure its continued prominence as a cornerstone technology, delivering exceptional value and consistent results.

References

- American Water Works Association (AWWA). (2017). Water Treatment Plant Design. 5th Ed. McGraw-Hill Education.

- Perry, R. H., & Green, D. W. (Eds.). (2007). Perry's Chemical Engineers' Handbook. 8th Ed. McGraw-Hill.

- National Research Council. (2008). Water Reuse: Potential for Expanding the Nation's Water Supply Through Reuse of Municipal Wastewater. The National Academies Press.

- International Organization for Standardization (ISO). ISO 9001:2015 Quality management systems – Requirements.