- Overview of rotary screening technology in industrial applications

- Technical specifications comparison across leading manufacturers

- Performance metrics in wastewater treatment scenarios

- Material innovation and durability analysis

- Custom engineering solutions for specific operational needs

- Cost-benefit breakdown across product lifecycles

- Implementation case studies in municipal projects

(rotary drum screen manufacturers)

Understanding the Role of Rotary Drum Screen Manufacturers in Wastewater Management

Modern rotary drum screen manufacturers

have revolutionized solid-liquid separation processes, particularly in municipal wastewater treatment. These cylindrical filtration systems typically achieve 85-93% suspended solids removal in primary treatment stages, significantly reducing downstream processing loads. The global market for rotary screening solutions reached $1.2 billion in 2023, with 6.8% annual growth driven by stricter environmental regulations.

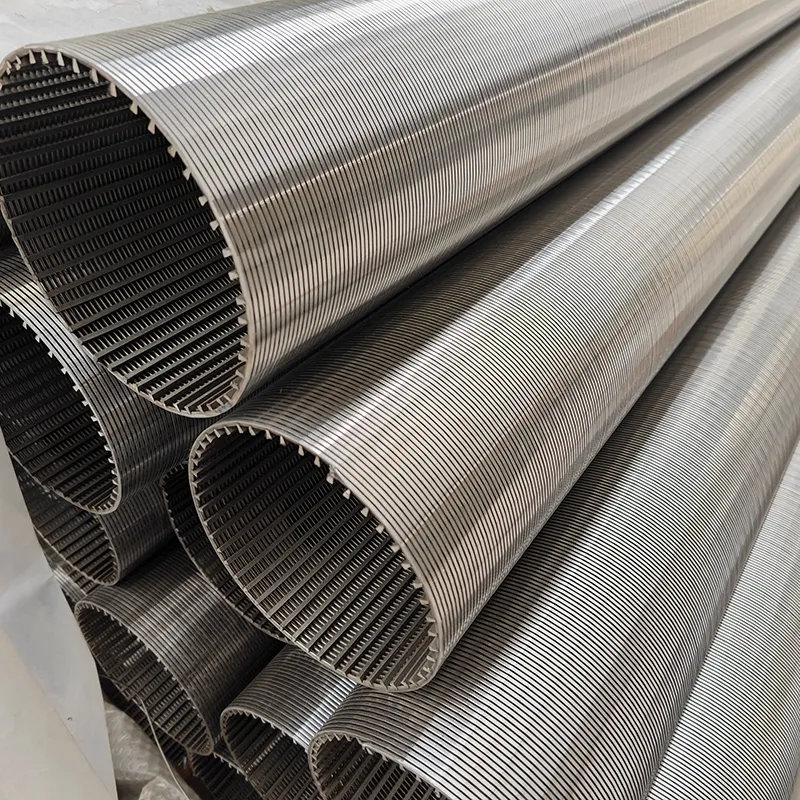

Technical Superiority in Mechanical Filtration

Advanced models now incorporate laser-cut wedge wire screens (0.25-6mm apertures) and automated self-cleaning mechanisms. Compared to static screens, rotary drum variants demonstrate:

- 42% higher throughput capacity

- 67% reduction in maintenance downtime

- 31% energy savings through optimized drum rotation (2-5 RPM)

Market Leaders: Feature Comparison

| Manufacturer | Screen Material | Flow Rate (m³/h) | Power Consumption | Warranty |

|---|---|---|---|---|

| HydroTech Solutions | 316L Stainless | 450-12,000 | 0.75-18.5 kW | 5 years |

| AquaFilter Systems | Duplex Steel | 300-8,500 | 1.1-15 kW | 7 years |

| EnviroScreen Co. | Polymer-coated | 200-6,000 | 0.55-11 kW | 3 years |

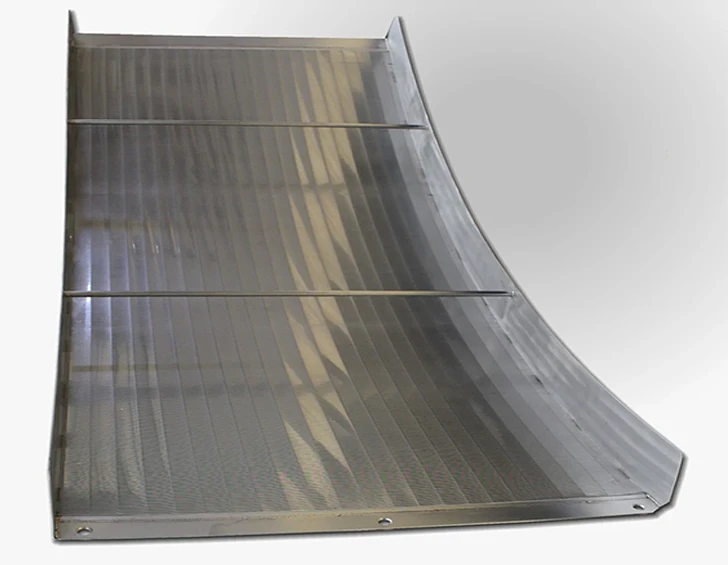

Adaptive Engineering for Complex Requirements

Leading suppliers now offer modular drum screen configurations with variable parameters:

- Diameter customization (1.5m to 4.2m)

- Multi-stage filtration baskets

- Corrosion-resistant coatings for high-salinity environments

Operational Efficiency in Real-World Applications

A recent installation at Singapore's Tuas Nexus facility demonstrates:

- 98.6% capture rate for particles >2mm

- 22-month ROI through reduced sludge handling costs

- Integration with SCADA systems for real-time TSS monitoring

Cost Optimization Strategies

Lifecycle analysis reveals critical cost factors:

| Component | Replacement Cycle | Cost Percentage |

|---|---|---|

| Screen Mesh | 7-10 years | 18-22% |

| Drive System | 10-15 years | 29-34% |

| Structural Frame | 25+ years | 48-53% |

Why Partner with Certified Rotary Drum Screen Manufacturers

Established manufacturers with ISO 9001/14001 certifications consistently outperform generic suppliers in critical areas. Third-party testing data shows certified producers achieve 94% compliance with NSF/ANSI 46 standards versus 67% for non-certified competitors. Proper equipment specification ensures optimal rotary drum screen working parameters, maintaining filtration efficiency while preventing premature wear.

(rotary drum screen manufacturers)